VC-1F-240 SINGLE ZONE TEMPERATURE CONTROLLER

Installation, Operation, & Maintenance Manual

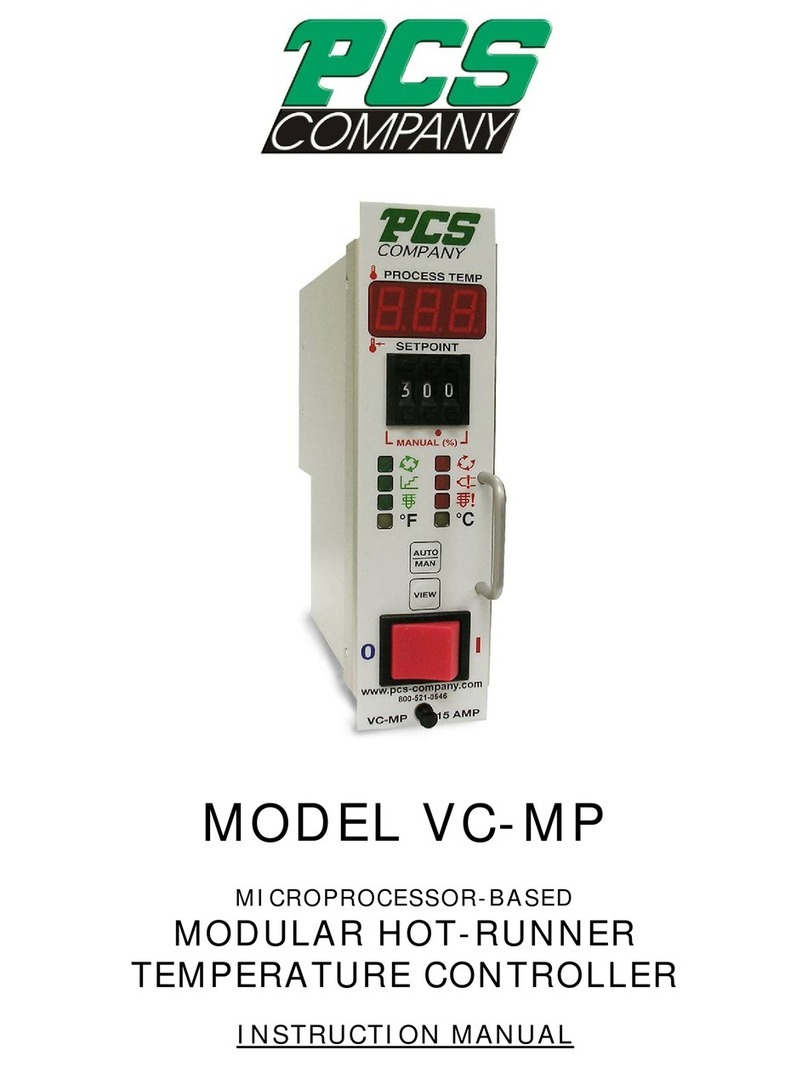

PRODUCT SPECIFICATIONS:

Voltage................................................................. 208 to 240vac, single phase

Current............................................................................. 15amps

Frequency............................................................. 50/60 Hz

Wattage............................................................................ 3600

Physical Configuration ........................................ An inclusive self-contained system

Size .................................................................. 6-1/2” Wide, 1-1/2” High, 10” Deep,

Weight ........................................................................ 3 #

DC Power Supply ................................................ Internally generated regulated and compensated

Control Systems Power Usage ............................ Less than 5 watts, excluding load

Set point Range .............................................................. 0oto 999oF (537oC)

Control Accuracy................................................. +/- 1oF (0.5oC) dependent on total thermal system

Calibration Accuracy ........................................... Better than 0.2% of full range

Operating Temperature Range............................. 32 to 120 degrees F

Thermocouple ...................................................... Type J, or Type K grounded or ungrounded

External Thermocouple Resistance..................... .High impedance potentiometer input allows long distance T/C

wiring

Thermocouple Isolation........................................Isolate from ground & supply voltage

Output Drive ........................................................ Internal solid state triac, zero crossing AC pulses

High/Low Te mperature Alarm............................ Factory set @ +/- 30 degrees F

Overload Protection ............................................. Fuses on both sides of AC line

Transient Protection ............................................ dv/dt and transient pulse suppression

Shorted Triac Heater Protection .......................... Highly sensitive, fast acting relays cut power to load

Power Line Isolation ........................................... Optically and transformer isolated from AC lines. Isolation voltage

greater than 2500 volts

Display................................................................. Dual LED displays, 3-digit, 7-segment

Manual Mode........................................................Maintains constant output power to within 1% of manual set power.

Adjustable from 0 to 100%

Soft Start .............................................................. Variable stepped voltage, phase fired

Soft Start Duration............................................... 5 Minutes (Adjustable) up to 212 degrees F

Soft Start Override Temperature........................... 212oF

Operational Modes ............................................. ..Soft Start precedes Auto Mode.

Thermocouple break overrides Soft Start and Auto Mode.

Reversed or shorted thermocouple overrides Soft Start and Auto

Mode.

Manual Mode overrides thermocouple break, reversed, shorted

thermocouple and Auto Mode.

Output is disabled during all fault conditions.

Cold Junction Compensation ............................... Automatic, better than 0.02oF/Fo(0.01oC/C)

Open Thermocouple Protection .......................... Automatically disables power to heater or Average Power Output

(APO). Selectable

Reversed Thermocouple Protection..................... Automatically disables power to heater.

Shorted Thermocouple Protection ....................... . Automatically disables power to heater or Average Power Output

(APO). Selectable

Warranty.......................................................................... 2-Years (exclude fuses and triac)

Phone: 800-521-0546 E-mail: sales@pcs-company.com Fax: 800-505-3299

www.pcs-company.com