FOOD DRYING APPLICATIONS (e.g. SAUSAGES) - HEATING MODE WITH COUNTDOWN

When the parameter rHC = 2, the relay operates in heating mode based on the parameter Hod while “SET”is displayed. By pressing the relay is activated and the

indication “rUn” is displayed. By pressing the remaining time is displayed. When timeρelapses, the relay is deactivated and “End” is displayed on screen. By pressing

again, the procedure starts over. The thermostat constantly controls the relay based on the adjusted Set Point (SPo). If SPo changes during “rUn”, automatically the

control of the relay is adjusted. If timer “Hod”changes during “rUn”mode, it will not change until the next running cycle.

ATTENTION: according to safety standards, the device must be properly positioned and protected from any contact with electrical parts. The device must be fastened in such a way that it cannot

be removed without the use of tools. Disconnect the main safety switch of the installation before proceeding to any maintenance. Disconnect the power supply of the device before proceeding to

any maintenance. Do not place the device near heat sources, equipment containing strong magnets, in areas affected by direct sunlight or rain. Prevent electrostatic discharges and sharp objects

from been inserted to the device. Separate signal cables from power supply cables to prevent electromagnetic disorders. Signal cables must never be in the same pipe with the power supply cables.

ATTENTION: Read carefully the technical specifications and make sure that the working conditions are appropriate. According to safety standards, the device must be fastened in such a way that

it cannot be removed without the use of tools.

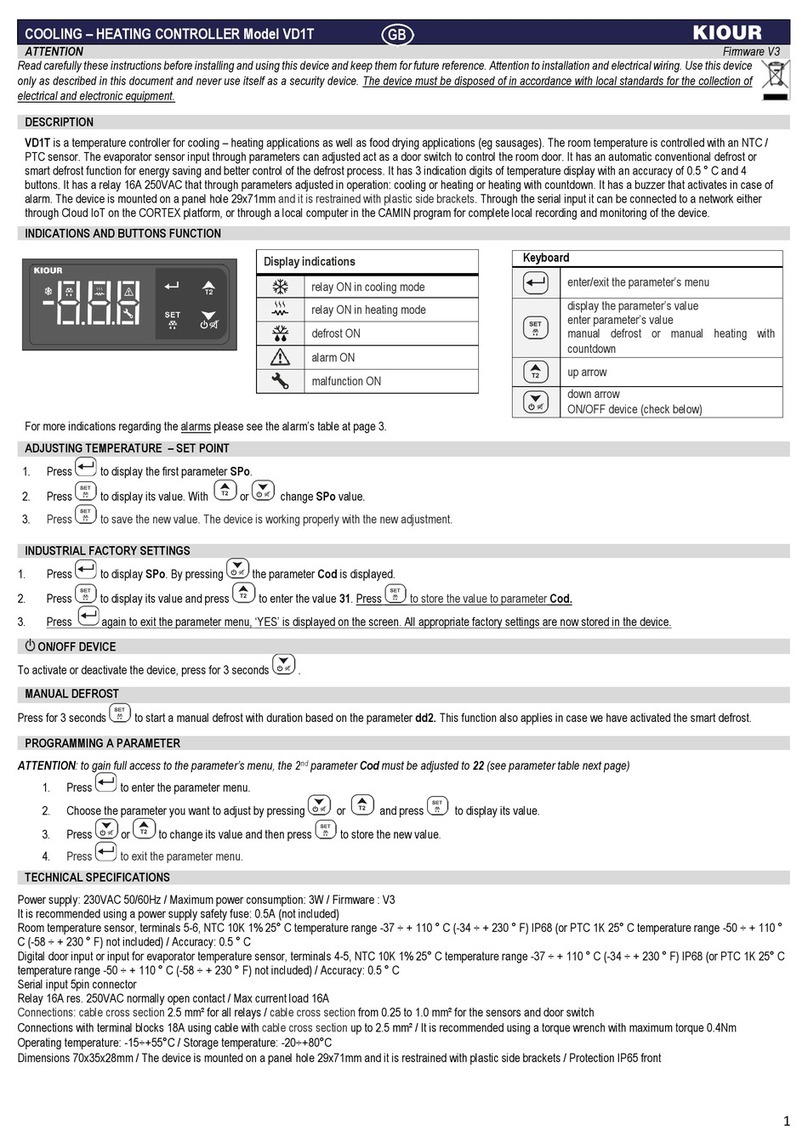

Dimensions are in mm. The device is mounted on panel hole with cut 29x71mm and restrained with plastic side brackets.

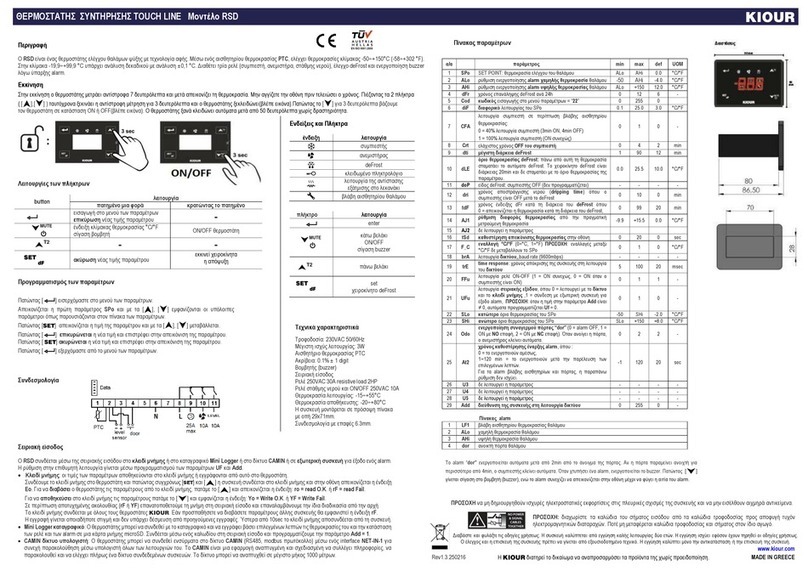

SET POINT: room temperature setting

Lower setting limit of SPo

Maximum setting limit of SPo

Differential of room temperature SPo (thermostat delay)

Access code to the following parameters Cod = 22.

Compressor’s minimum time OFF

Compressor’s operation in case of sensor’s malfunction (LF1) and in cooling mode:

0 = 40% compressor’s operation (3min ΟΝ, 4min OFF) / 1 = compressor is ΟΝ continuously.

In heating mode the relay is deactivated.

Time between two successive defrost: where dFr = 0 or relay in heating mode, the defrost is deactivated.

Defrost duration (manual and automatic)

Defrost end temperature is the room temperature

Automatic defrost stops if room temperature is greater than defrost end temperature dE5.

Manual defrost starts regardless of the room’s temperature and ends after time adjusted in parameter dd2 elapses.

Dripping timer, where the compressor is OFF after defrost

Display indication during defrost

0 = indication of room’s temperature

1 to 40 min = indication of “dFr” from 1 to 40 min counting from the beginning of defrost

Time delay for refreshing the temperature indication on screen

Temperature measurement unit: toggling between °C/°F do not adjust the SPo automatically, it must be changed by the user

0 = °C / 1 = °F

Countdown timer when the relay is in heating mode with countdown, adjust also parameter rHC = 2

Response time of the device on network

Time delay in activating “AΗi”, “ΑLo” and the buzzer among them.

This setting does not apply to sensor failure “LF1” and door alarm “dor”.

High alarm room threshold

Door switch operation

0=OFF / 1 = NC (normally close) / 2 = NO (normally open)

In heating mode, the door switch is deactivated.

Time delay in activating the high temperature alarm “AHi” after defrost.

During deFrost, the alarm “AHi” is deactivated.

Time delay when the doors open, for the deactivation of the compressor and the activation of open door alarm “dor”

When the door closes, the compressor starts to operate and the alarm disappears.

Relay operation, where 0 = cooling / 1 = heating / 2 = heating with countdown based on timer Hod

Temperature indication as integer or decimal, where 0 = integer / 1 = decimal

Device address on network. To connect with Mini Logger enter Add=1.

Sensor type NTC/PTC

0 = PTC / 1 = NTC

Error in memory RAM: re-enter the SPo (see ADJUSTING TEMPERATURE –SET POINT back page)

The alarms are automatically deactivated when the cause of the alarm disappears.

Made in Greece.

The device is under two year’s guarantee. The guarantee is valid only if the manual instructions have been applied. The control and service of the device must be done by an authorized technician.

The guarantee covers only the replacement or the service of the device. KIOUR preserves the right to adjust its products without further notice.

392

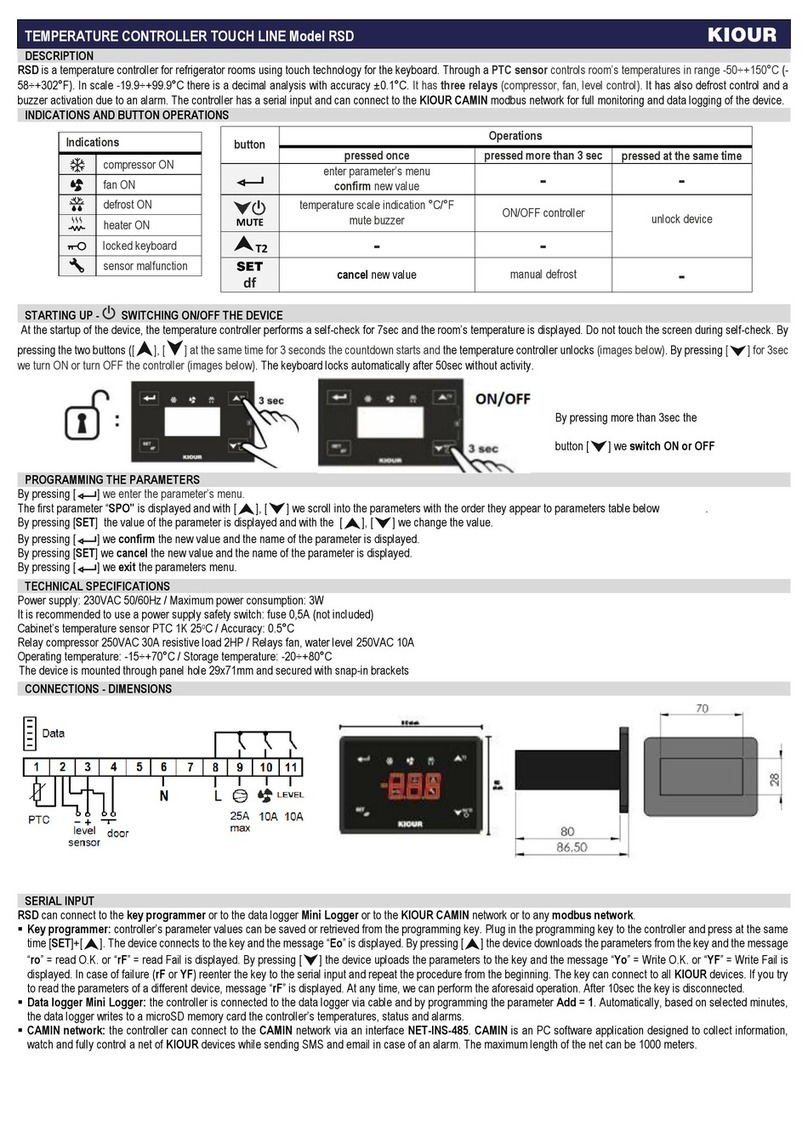

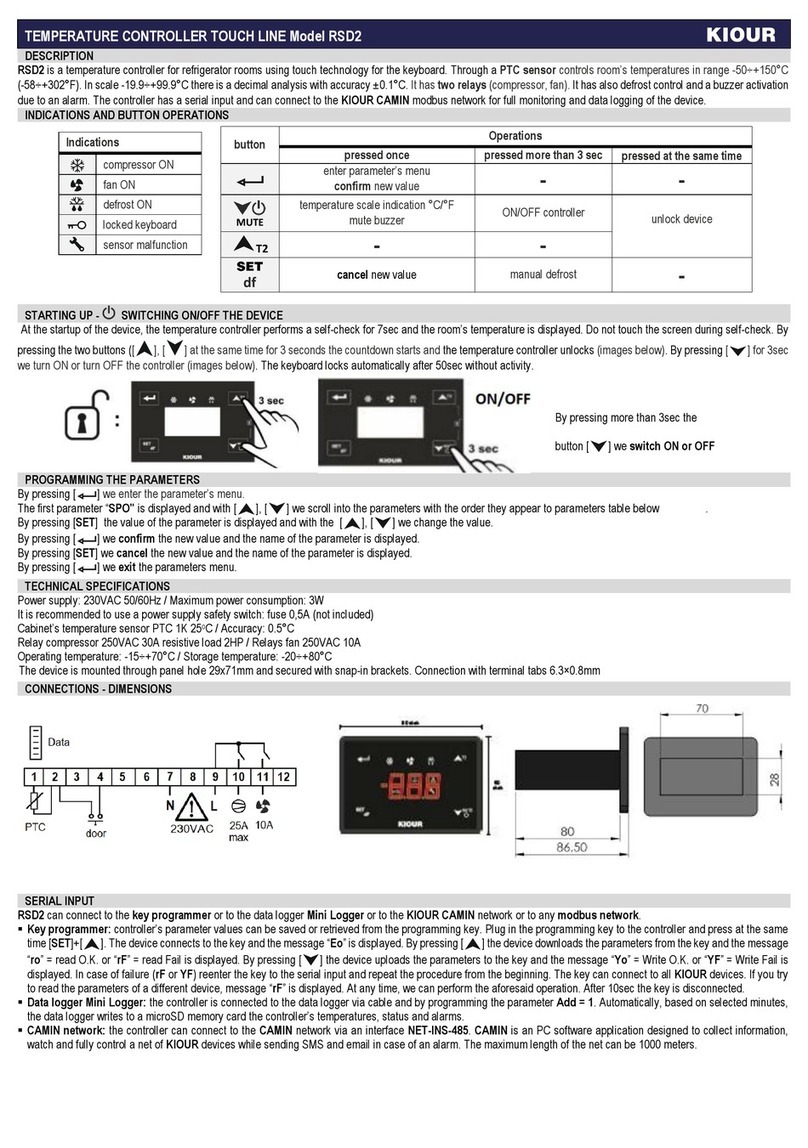

Mesogeion Avenue Agia Paraskevi 153 41 Τ: 210 6533730 F: 210 6546331 [email protected] www.kiour.com ELECTRICAL DIAGRAM - DIMENSIONS