PEAK COMMUNICATIONS DBUH Series User manual

Handbook Issue 3.20, 12th March 2017

1997

EN 55022 CLASS B

EN 50082-1

EN 60950

PEAK COMMUNICATIONS Ltd.

Unit 1, The Woodvale Centre, Woodvale Road,

Brighouse, West Yorkshire

HD6 4AB, England

Phone 01484 714200

Fax 01484 723666

IMPORTANT NOTE: THE INFORMATION AND SPECIFICATIONS CONTAINED IN THIS

DOCUMENT SUPERCEDE ALL PREVIOUSLY PUBLISHED INFORMATION CONCERNING

THIS PRODUCT

PEAK COMMUNICATIONS Ltd maintains a continuing programme of product improvement

and therefore reserves the right to change specifications without notice

Installation and Operating Handbook

DBUH / DLAH / DTLH Dual Hot Swappable

Converters/ Line Amplifiers /Test Loop

Translators

Issue 3.20 DBUH / DLAH / DTLH Installation and Operation Handbook Page 2

Table of Contents

INTRODUCTION.................................................................................................................................................................... 3

EMC AND SAFETY................................................................................................................................................................ 3

EMC...................................................................................................................................................................................... 3

Safety................................................................................................................................................................................... 4

INSTALLATION ...................................................................................................................................................................... 4

UNIT DESCRIPTION............................................................................................................................................................. 5

Front Panel Description......................................................................................................................................................... 5

Keyboard ............................................................................................................................................................................ 5

LCD display........................................................................................................................................................................ 5

LED Indicator..................................................................................................................................................................... 5

REAR PANEL DESCRIPTION ............................................................................................................................................. 5

REAR PANEL PINOUTS....................................................................................................................................................... 6

OPERATION........................................................................................................................................................................... 7

Menu Structure........................................................................................................................................................................ 7

Operating display............................................................................................................................................................. 7

Status .................................................................................................................................................................................. 7

Configure............................................................................................................................................................................ 8

Attenuation......................................................................................................................................................................... 8

Remote control.................................................................................................................................................................. 8

Log..................................................................................................................................................................................... 10

Service............................................................................................................................................................................... 10

REDUNDANCY / MUTE...................................................................................................................................................... 11

WEBSITE PASSWORDS / SNMP COMMUNITIES........................................................................................................ 12

Setup.................................................................................................................................................................................. 13

REMOTE CONTROL........................................................................................................................................................... 14

Serial Communications RS232 / 485.......................................................................................................................... 14

Ethernet............................................................................................................................................................................. 21

Issue 3.20 DBUH / DLAH / DTLH Installation and Operation Handbook Page 3

INTRODUCTION

The equipment’s covered by this manual are high grade units which can be applied to many

situations where good stability and phase noise etc are required.

The specification for the particular model purchased can be found at the end of this manual.

EMC AND SAFETY

EMC

The equipment has been designed to comply with the following standards;

Emissions : EN 55022 Class B; Limits and methods of measurement of radio interference

characteristics of Information Technology Equipment.

Immunity : EN 50082 Part 1; Generic immunity standard, part 1: Domestic, commercial and

light industrial environment.

The equipment must be operated with its lid on at all times. If it is necessary to remove the lid for

routine servicing or fault finding then it is essential that the lid is fitted back correctly before normal

operation.

For the Alarm and Remote Control data interfaces all 'D' type connectors must have grounding

fingers on the plug shell to guarantee continuous shielding. The back-shells must comply to the

requirements of VDE 0871 and FCC 20708, providing at least 40 dB of attenuation from 30 MHz

to 1 GHz.

Connecting cables must be of the shielded type

Operation of the equipment in a non standard manner will invalidate compliancy to these

standards.

Issue 3.20 DBUH / DLAH / DTLH Installation and Operation Handbook Page 4

Safety

To ensure safety of the operator the equipment has been designed to comply with the following

safety standard;

EN 60950 Safety of information technology equipment, including electrical business machines.

Before operation the user must ensure that the installation complies with the information given.

The equipment is designed to operate in a static 19 inch rack system conforming to IEC 297-2.

Operation of the equipment in transportable vehicles equipped with the means of providing a

stable environment is permissible. Operation of the equipment on board vehicles, ships or aircraft

without means of environmental conditioning will invalidate the safety compliancy; please contact

the factory for further advice. Operation of the equipment in an environment other than that stated

in the specifications will also invalidate the safety compliancy. The equipment must not be

operated above 2000 metre altitude, extremes of temperature; excessive dust, moisture or

vibration; flammable gases; corrosive or explosive atmospheres.

INSTALLATION

The equipment is classified in EN 60950 as a pluggable equipment class A for connection to the

mains supply, as such it is provided with a mains inlet cord suitable for use in the country of

operation. In normal circumstances this will be of an adequate length for installation in the rack. If

the mains cord proves to be too short then any replacement must have a similar type fuse (if

fitted) and be manufactured to similar specification: check for HAR, BASEC or HOXXX-X ratings

on the cable. The connector ends should be marked with one of the following : BS1636A (UK free

plug 13 amp); BSI, VDE, NF-USE, UL, CSA, OVE, CEBEC, NEMKO, DEMKO, SETI, IMQ, SEV

and KEMA-KEUR for the IEC 6 amp free socket. Schuko and North American free plugs must

have similar markings.

The installation of the equipment and the connection to the mains supply must be made in

compliance to local or national wiring regulations for a category II impulse over voltage

installation. The positioning of the equipment must be such that the mains supply socket outlet for

the equipment should be near the equipment and easily accessible or that there should be

another suitable means of disconnection from the mains supply.

The equipment is designed to operate from a TN type power supply system as specified in EN

60950. This is a system that has separate earth, line and neutral conductors. The equipment is

not designed to operate with an IT power system which has no direct connection to earth.

Issue 3.20 DBUH / DLAH / DTLH Installation and Operation Handbook Page 5

UNIT DESCRIPTION

STATUS

CANCEL

NO / 6 7 8 9 0

ENTER

YES / 1 2 3 4 5

DUAL BLOCK UNIT

DLAH200

115/230 VOLTS AC

PSU1

MODEL NO.:

A2

UB1

50/60 Hz UA1 SERIAL NO.:

OutputInput 1

MODEL NO.:

Ethernet 2

Interface

Input Output

SERIAL NO.:

UB2

A2

UA2

Ext Ref.

50 Watts Max

PSU2

Front Panel Description

Keyboard

The keyboard is of the membrane type and is an integral part of the front panel assembly. The

front panel overlay and is completely sealed against penetration of liquids but caution should

be taken especially with solvents which may damage the front screen.

There are 16 keys in total - number keys in the range 0 to 9, YES/ENTER and NO/CANCEL

and a 4 way arrow block of keys

LCD display

The backlit display is a graphic display and characters are scaled to incorporate as much

information as possible on the screen. It provides detailed information about the status and

configuration of the unit, and when appropriate, prompts the user to enter data via the keypad.

LED Indicator

Only one tricolour LED is present, marked STATUS. This shows GREEN when the unit is OK,

RED when an internal fault is present and AMBER when in STANDBY (Redundancy operation)

An Internal alarm is caused by Power failure, Amplifier failure or Unit out of lock.

REAR PANEL DESCRIPTION

EXT. Ref External Reference input.

Interface Alarms connection.

Ethernet Ethernet connection if option is fitted.

Other rear panel connections maybe applicable to the specific unit purchased please check the

specification.

Issue 3.20 DBUH / DLAH / DTLH Installation and Operation Handbook Page 6

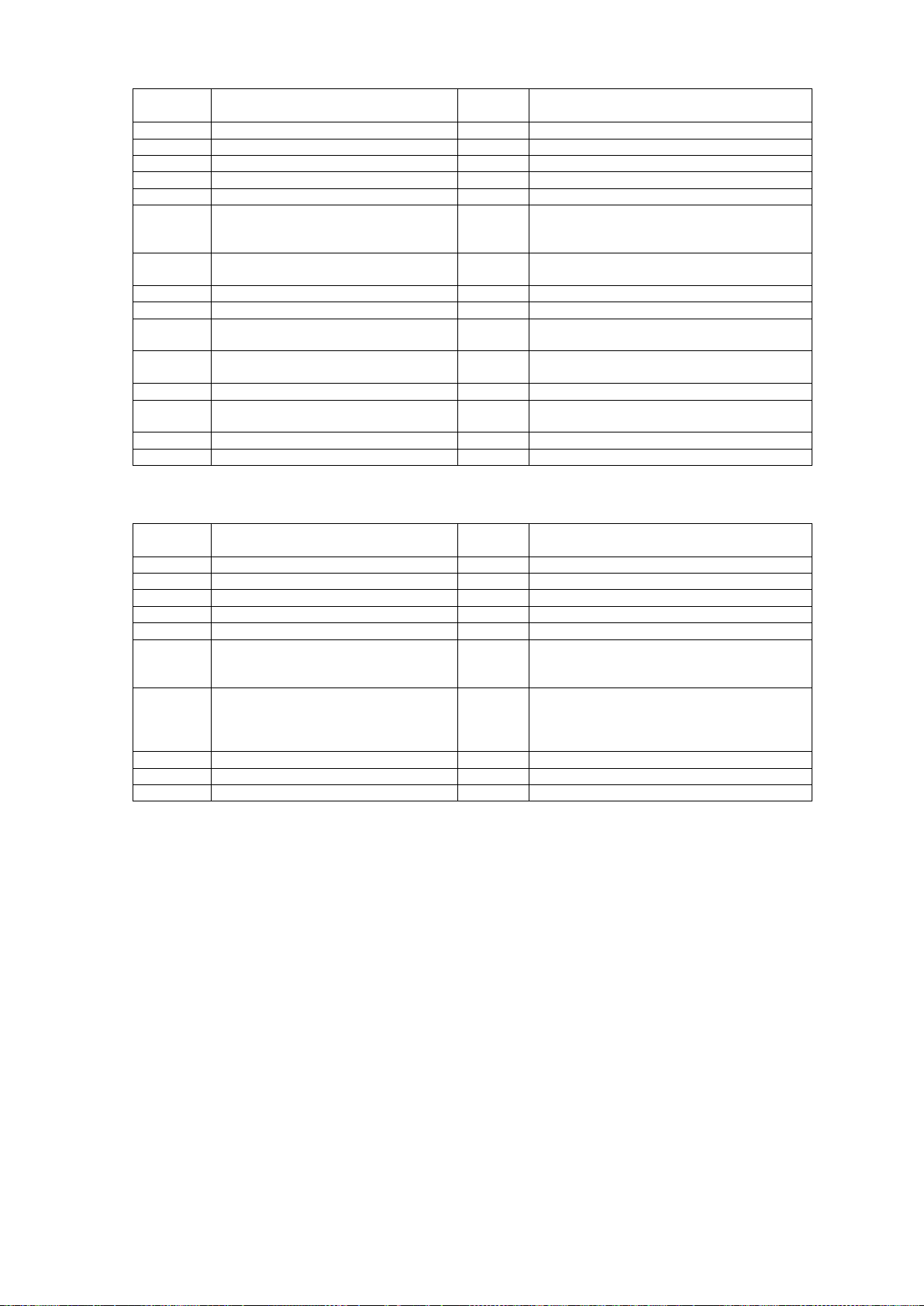

REAR PANEL PINOUTS

INTERFACE Alarms monitoring and control of the units.

REMOTE (If Ethernet option is not fitted) Alarms monitoring and control of the units.

Ethernet (If option fitted)

RJ45 8P8C female connector

Module 2 Amplifier N/C

1

Module 2 Amp Common

2

Module 2 LO N/O

3

Module 2 LO Common

4

Module 2 Summary Alm N/O

5

Module 2 Summary Alm

Common

6

Module 2 Online

7

Ground

8

9

Module 1 Amplifier N/C

10

Module 1 Amp Common

11

Module 1 LO N/O

12

Module 1 LO Common

13

Module 1 Summary Alm N/O

14

Module 1 Summary Alm

Common

15

Module 1 Online

RS485 Rx +

1

RS485 Tx +

2

Not used

3

Not used

4

Not used

5

Not used

6

RS232 Rx In

7

Not used

8

9

RS485 Rx -

10

RS485 Tx -

11

Not used

12

Not used

13

Not used

14

GROUND

15

RS232 Tx Out

Issue 3.20 DBUH / DLAH / DTLH Installation and Operation Handbook Page 7

OPERATION

On switching on the unit the STATUS indicator on the front of the unit should turn GREEN if all

is OK.

The modules are inserted from the rear of the DBUH/DLAH, please refer to the DBUH/DLAH

datasheet for the inserted modules’ performance.

Menu Structure

On Power up the unit will start in HOME mode displaying the following options.

Generally YES will select/enable an item and NO will step back one step with no changes.

The unit’s HOME screen has 5 main menu options as shown in Figure 1 below:

Operating display

This menu shows a graphical representation of the RF path and attenuation values, the screen

is different if the unit is fitted with the redundancy option.

Figure 2

Status

This menu shows an immediate summary of all settings and alarm conditions, more details

may be available by pressing the down arrow, left and right arrows cycle through the attached

trays.

Figure 1

Figure 3

Issue 3.20 DBUH / DLAH / DTLH Installation and Operation Handbook Page 8

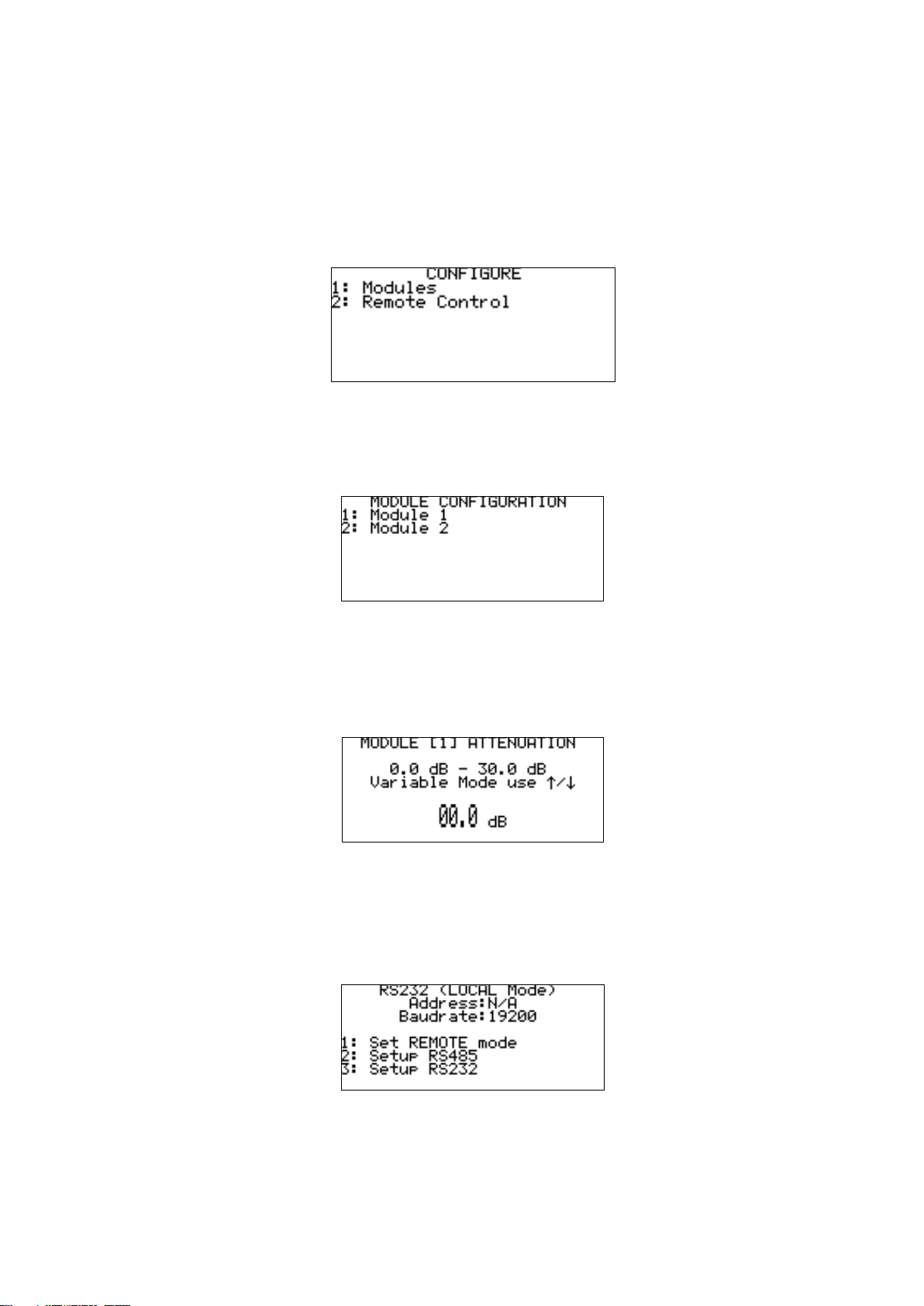

Configure

This menu allows the user to configure different parts of the unit, the menu choice change

depending on the unit, its options, and whether the unit is in remote or local mode.

When in local mode all the menu items are available to the user to change, when in remote

mode only the REMOTE CONTROL menu option is available.

Figure 3, below, shows a basic configure menu, however as stated above the menu choices

change depending on the unit, the installed trays and their options.

The possible list of tray options that have their own configure menu items and associated

configuration screens including:

Figure 5

Attenuation

Allows the attenuation of the RF path of the selected tray to be changed, the step size and

range are tray/option specific.

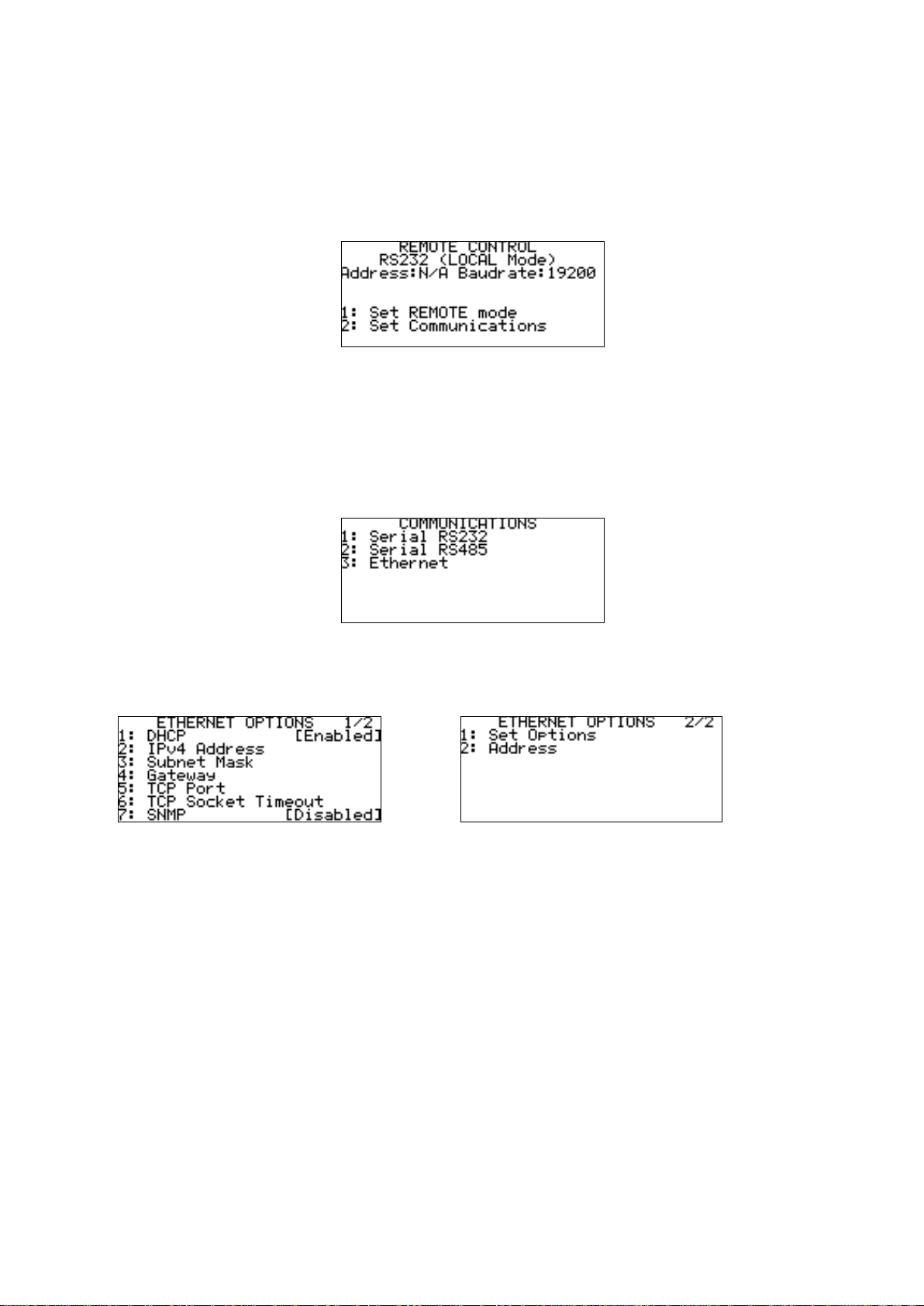

Remote control

Selects a sub-menu with further menus. If the Ethernet module is not installed then the

following menu will be shown:

Figure 4

Figure 7

Figure 6

Issue 3.20 DBUH / DLAH / DTLH Installation and Operation Handbook Page 9

1 Set REMOTE mode - Sets the unit to allow control from a remote source. Pressing 1 again

returns the unit to local mode.

2 SETUP RS485 - Allows the selection of RS485 UNIT ADDRESS and BAUD RATE.

3 SETUP RS232 - Allows selection of BAUD RATE for RS232 communication.

If the Ethernet module is fitted then the menus change slightly to:

1 Set REMOTE mode - Sets the unit to allow control from a remote source. Pressing 1 again

returns the unit to local mode.

2 Setup Communications - Allows the selection of RS485, RS232 or Ethernet communication.

RS232, RS485 menus work in the same way as shown above.

3 Ethernet –This brings up a further menu as shown below in figures 11 and 12, these are

accessed by using the up/down buttons

The menu choices (1-4) shown in figure 11 allow the user to change the relevant Ethernet

settings of the unit.

5 TCP Port –Sets the TCP port number used that allows serial comms messages to be sent,

via Ethernet, to the unit.

6 TCP Socket Timeout –Sets the timeout value, after which time if no communication is

received on the open TCP socket it is closed.

7 SNMP –Allows the SNMP protocol to be turned Disabled/Enabled.

1 SNMP Trap Address –Sets the IP address of the device that will receive any SNMP trap

error messages from the unit.

Set Options in figure 12 is used to set the Ethernet data all at once on the device, this must be

used when trying to change the Ethernet settings.

Figure 8

Figure 9

Figure 10

Figure 11

Issue 3.20 DBUH / DLAH / DTLH Installation and Operation Handbook Page 10

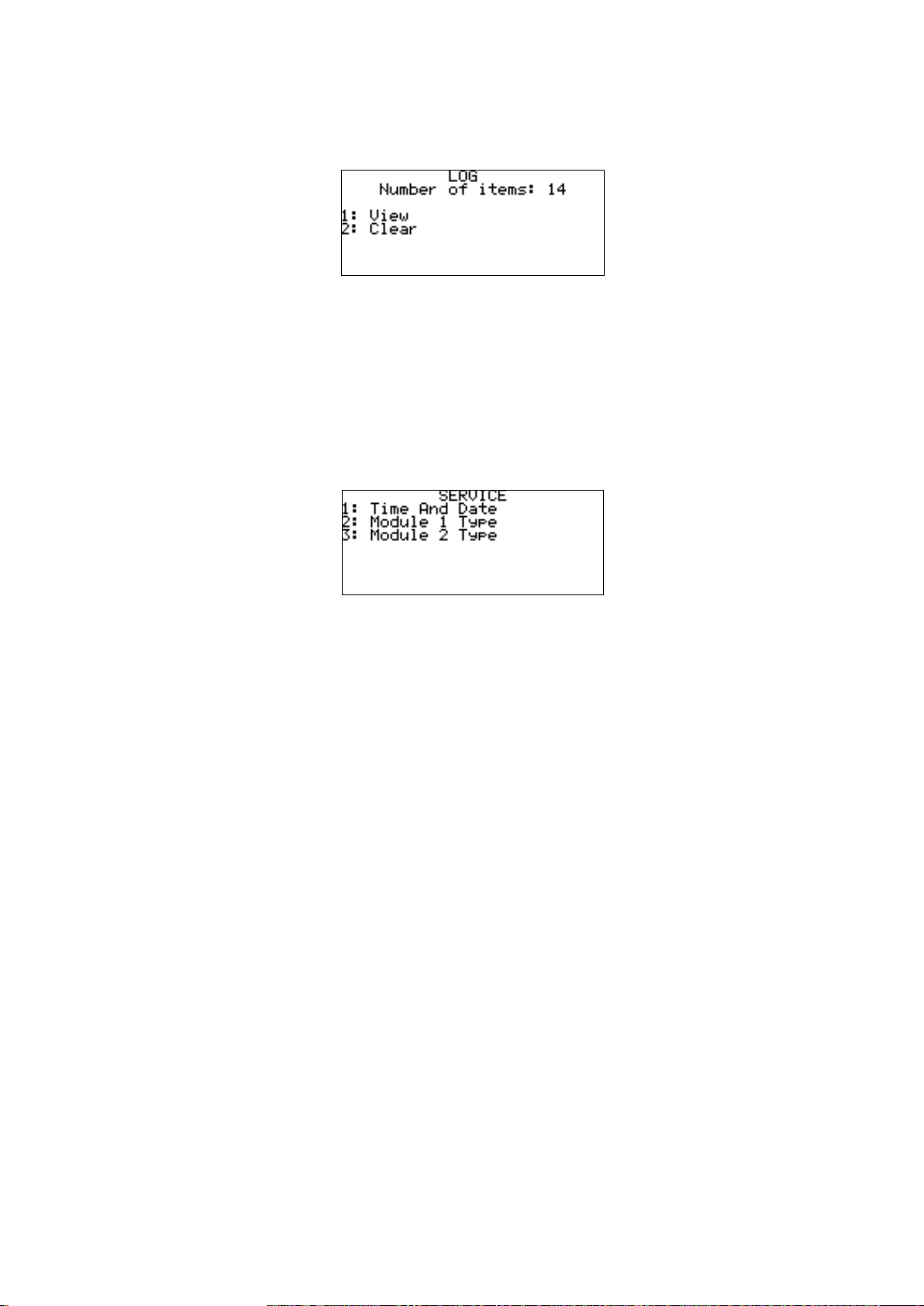

Log

This provides an event log of any ‘errors’or ‘events’that have occurred.

1 View - Displays the stored logs.

2 Clear - Allows the user to clear the log.

Service

This menu has 3 submenus as shown below in figure 13.

1 Time And Date - Allows setting of current time and date

2 Module 1 Type - Allows selection of installed module type

3 Module 2 Type - Allows selection of installed module type

Figure 12

Figure 13

Issue 3.20 DBUH / DLAH / DTLH Installation and Operation Handbook Page 11

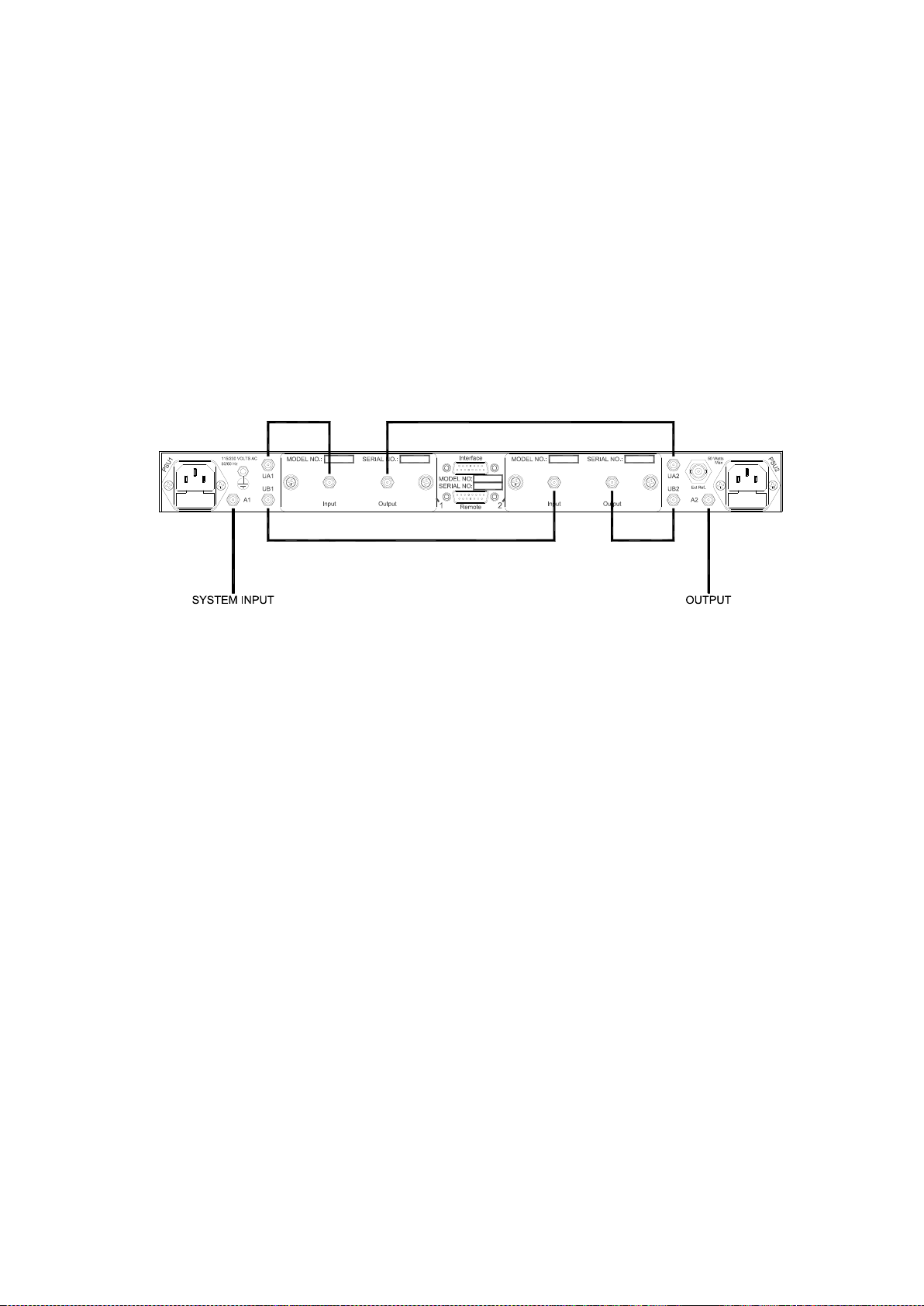

REDUNDANCY / MUTE

The redundancy option allows the user to select which tray is online, either A or B. Alternatively,

Auto mode can be selected, allowing the automatic switching in/out of faulty trays.

If the unit also has the mute option fitted, then the output of the redundancy system can be

muted via one of the unit’s user interfaces e.g. menu.

Where the DBUH/ DLAH/ DTLH is purchased as a redundant system with two identical MBUH/

MBDH/ MLAH/ MTLH modules, the rear panel cabling configuration is shown below.

The customer is required to supply the system input and output cables. Peak Communications

will supply the interconnecting cables unless instructed otherwise.

Issue 3.20 DBUH / DLAH / DTLH Installation and Operation Handbook Page 12

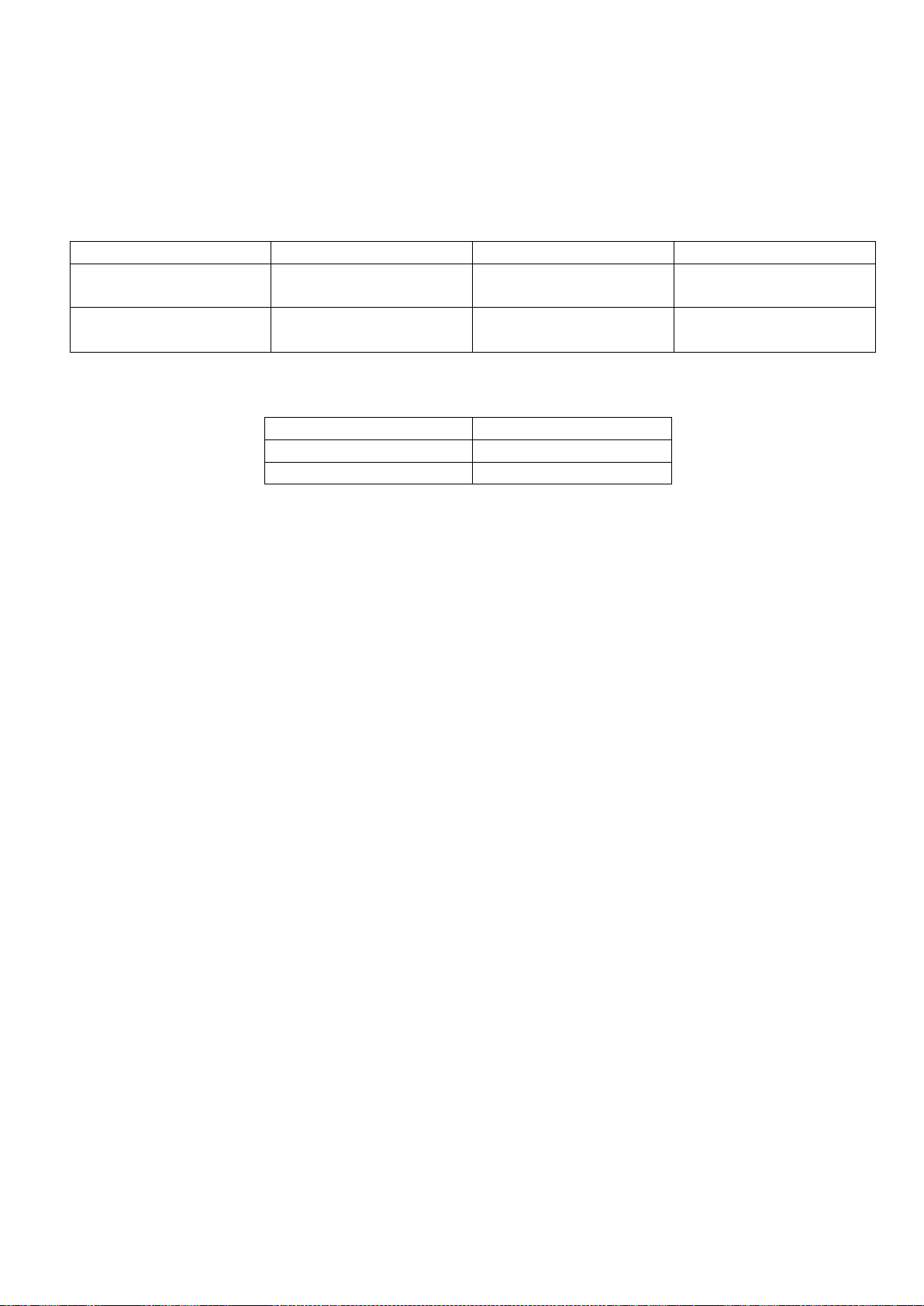

WEBSITE PASSWORDS / SNMP COMMUNITIES

From DXXH software version 1.32 onwards the website offers a simple form of password

protection for the webpages, as well as the ability to change the SNMP community names.

There are two user logins for the webpages, these are shown in the table below, along with

their default user names and passwords:

Type

User Name

Password

Description

Read only

readonly

readonly

Access to status

pages only.

Read write

readwrite

readwrite

Access to status and

config pages.

The default SNMP community names are shown in the table below:

Community

Name

Read

public

Set / write

private

In order for webpages to be accessible the user must login, using one of the above usernames.

The logged in user name and password can be changed via the website.

When using the read write user, the SNMP community names can also be changed.

The passwords are as standard disabled, they can be enabled via the front panel of the unit.

The default passwords / SNMP community names can also be reset to their default via the front

panel.

Issue 3.20 DBUH / DLAH / DTLH Installation and Operation Handbook Page 13

Setup

This menu, as shown in figure 14, is hidden and shouldn’t normally be used by operators.

However this is the menu that allows the resetting of passwords / communities, as well as

toggling the passwords on / off.

In order to get to this setup menu, the user presses keys 0 then 9 from the HOME menu.

1 Initial Setup –Allows the initial setup of the unit, this SHOULD NOT BE USED BY

CUSTOMERS AS A BAD SETUP MAY CAUSE PERMANENT UNIT DAMAGE.

2 Serial Number –Allows the setting of the unit’s serial number.

3 Modify Parameters - Allows modification of certain unit parameters. DO NOT USE

4 Program Checksum –Calculates the firmware checksum.

5 Reset Passwords –Resets all the passwords and community names back to their default

values, and turns the passwords / security off.

6 Toggle Passwords –Toggles the passwords / security on / off.

Menu items 5 & 6 are not available in Non Ethernet based units.

Figure 14

Issue 3.20 DBUH / DLAH / DTLH Installation and Operation Handbook Page 14

REMOTE CONTROL

Serial Communications RS232 / 485

The unit transmits and receives data serially in an asynchronous format using the standard

ASCII character set. The serial data consists of message frames composed of the following

message characters: STX, BYTE COUNT, UNIT ADDRESS, INSTRUCTION, BODY,

CHECKSUM, ETX. All characters are compulsory except for the message body. The presence

of a message body is determined by the message type (INSTRUCTION). The total number of

message characters in a message frame may range from a minimum of 6 to a maximum of

255.

The remote control follows the following protocol: (in byte form)

[STX] start of message character #02.

[B] char defining how many characters are in the message including the STX & ETX parts.

[A] Address of unit. Address ranges from ASCII character 001 to 255. If in RS232 Mode

this address can be anything in the 001 to 255 range.

[I] Instruction number. See List below

[MESSAGE]

Numerous characters from length 0 upwards.

[CHKSUM]

The checksum is used to verify the accuracy of the message frame. The checksum is

defined as the summation of all the bytes in the message, beginning with the 3rd byte

(DEVICE ADDRESS) and extending through the body of the message, ending with the

last byte before the checksum. The total of the bytes is then ANDed with 255 so that the

checksum is truncated to a single byte.

[ETX] End of transmission character #03

All message to and from the unit follow the above protocol with a character format of 8 data

bits, one stop bit, no parity, baud rate 19200, 9600, 4800, 2400, 1200 or 300. Note; that all

numeric values are shown as decimal.

Issue 3.20 DBUH / DLAH / DTLH Installation and Operation Handbook Page 15

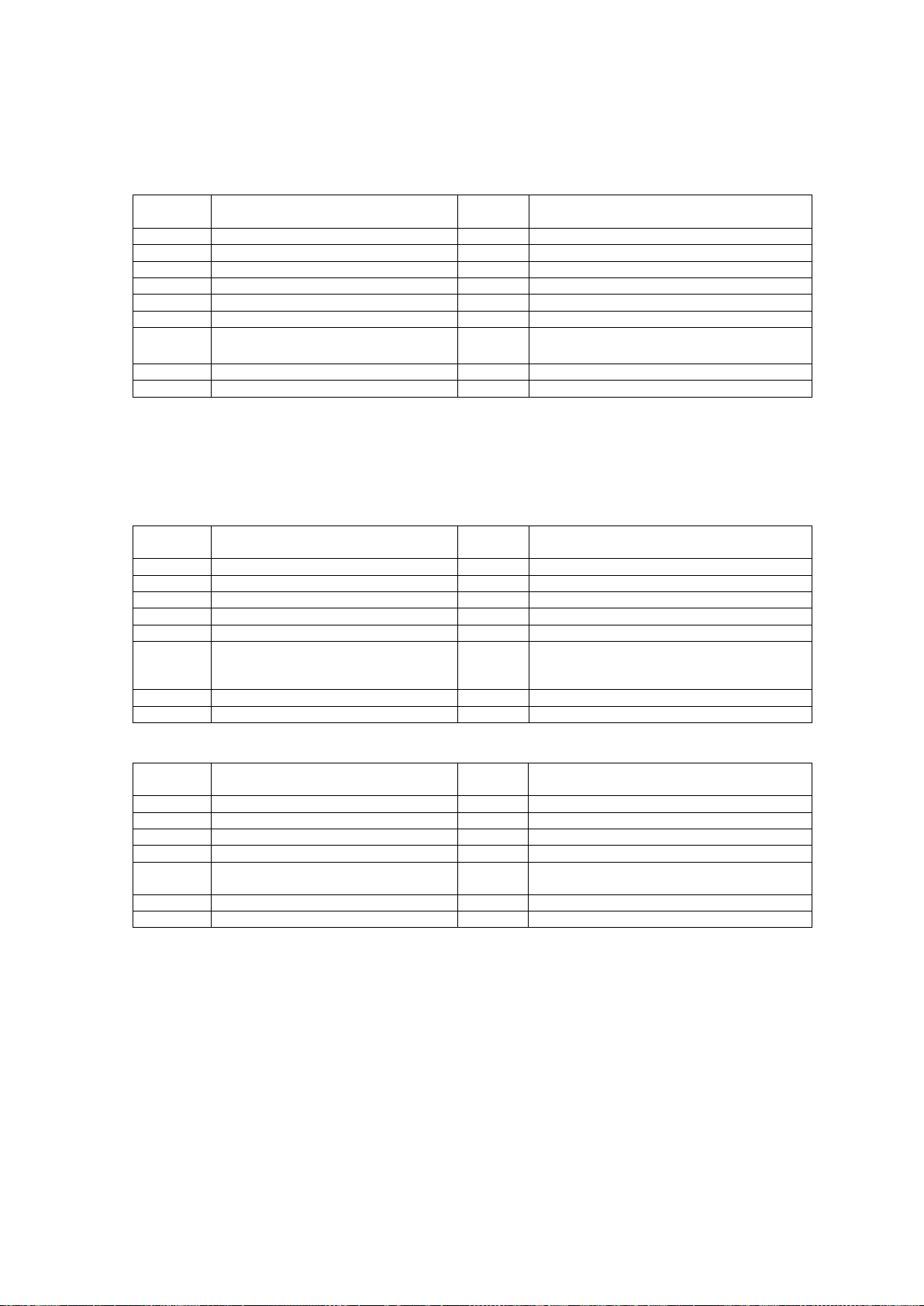

INSTRUCTION NUMBER LIST (IN DECIMAL)

To unit

From unit

Description

20

Requests Status

Allows different status request types:

Module Status Request

Power Supply Status Request

System Status Request

21

Responds Status

Allows different status response types:

Module Status Response

Power Supply Status Response

System Status Response

22

Reconfiguration Request

Single Channel Reconfiguration Request

System Reconfiguration Request

24

Set Remote/Local Mode request

40

Asks for the main Unit settings

41

Replies with the Unit Settings

42

Asks for the internal redundancy status

43

Replies with the internal redundancy status

44

Reconfiguration request for the internal redundancy.

Instruction 20 (Module Status Request)

Message

Byte No.

Set Value /

(example)

Length

(bytes)

Description

1

02

1

STX

2

?

1

No of bytes in message

3

?

1

Address

4

20

1

Message instruction

5

‘M’

1

Module

6

‘01’

2

Module number

8

?

1

Checksum

9

03

1

ETX

Issue 3.20 DBUH / DLAH / DTLH Installation and Operation Handbook Page 16

Instruction 20 (Power Supply Status Request)

Instruction 20 (System Status Request)

Instruction 21 (Module Status Request Reply)

Due to the ability of the DBUH/DLAH to accept differing module types into it, the module status request reply may

vary between these different module types.

If the channel is missing then the value of the rest of the bytes in the message is

undetermined.

Message

Byte No.

Set Value /

(example)

Length

(bytes)

Description

1

02

1

STX

2

?

1

No of bytes in message

3

?

1

Address

4

20

1

Message instruction

5

‘P’

1

Power supply

6

‘01’

2

Power supply number

8

?

1

Checksum

9

03

1

ETX

Message

Byte No.

Set Value /

(example)

Length

(bytes)

Description

1

02

1

STX

2

?

1

No of bytes in message

3

?

1

Address

4

20

1

Message instruction

5

‘S’

1

System

6

?

1

Checksum

7

03

1

ETX

Message

Byte No.

Set Value /

(example)

Length

(bytes)

Description

1

02

1

STX

2

?

1

No of bytes in message

3

?

1

Address

4

21

1

Message instruction

5

‘M’

1

Module

6

‘01’

2

Module number

8

‘-’

1

Module State:

Module Missing ‘X‘

Module Warmup ‘W’

Module Reference Warmup ‘R’

Module Present '-'

9

‘ MLAH175’

20

Module name/type

29

‘+123’

4

Attenuation asked for in 0.1 dB steps,

‘+123’ = 12.3dB

33

‘0’

1

External Reference

‘X‘ = Not present

‘L’ = Locked

‘U’ = Unlocked

34

‘….’

4

NOT USED

38

‘0’

1

Summary Alarm

‘0’ = OK ‘1’ = FAULT

39

‘0’

1

External Reference Fault

‘0’ = OK ‘1’ = FAULT

40

‘0’

1

PLO Fault

‘0’ = OK ‘1’ = FAULT

41

‘0’

1

Amplifier Fault

‘0’ = OK ‘1’ = FAULT

42

‘0’

1

Attenuator Fault

‘0’ = OK ‘1’ = FAULT

43

‘….‘

4

NOT USED

47

(‘23/12/02 12:34:56’)

17

OK Since time/date string, if there is a

fault then the string is blank.

64

?

1

Checksum

66

03

1

ETX

Issue 3.20 DBUH / DLAH / DTLH Installation and Operation Handbook Page 17

Instruction 21 (Power Supply Status Request Reply)

Instruction 21 (System Status Request Reply)

This message should only be used with units with the mute option fitted.

Message

Byte No.

Set Value /

(example)

Length

(bytes)

Description

1

02

1

STX

2

?

1

No of bytes in message

3

?

1

Address

4

21

1

Message instruction

5

‘P’

1

Power supply

6

‘01’

2

Power supply number

‘01’ = PSU 1

‘02’ = PSU 2

8

‘-‘

1

Power Supply Present

‘X’ = Missing ‘-’ = Present

9

‘.’

1

NOT USED

10

‘….’

4

NOT USED

14

‘0’

1

Summary Alarm

‘0’ = OK ‘1’ = FAULT

15

‘0’

1

Power Supply Missing

‘0’ = OK ‘1’ = FAULT

16

‘..’

2

NOT USED

18

(‘23/12/02 12:34:56’)

17

OK Since time/date string, if there is a

fault then the string is blank.

35

?

1

Checksum

36

03

1

ETX

Message

Byte No.

Set Value /

(example)

Length

(bytes)

Description

1

02

1

STX

2

?

1

No of bytes in message

3

?

1

Address

4

21

1

Message instruction

5

‘S’

1

Power supply

6

‘M’

1

Wanted mute status

‘U’ = Unmuted

‘M’ = Mute

7

‘M’

1

Actual mute status

‘U’ = Unmuted

‘M’ = Mute

‘?’ = Unknown

8

‘.….’

5

NOT USED

13

?

1

Checksum

14

03

1

ETX

Issue 3.20 DBUH / DLAH / DTLH Installation and Operation Handbook Page 18

Instruction 22 (Module Reconfiguration Requests)

The unit MUST be in remote mode to allow reconfiguration of parameters via the remote control. Setting the unit in

Remote mode can be done either by the front panel or remotely using the instruction 24.

Due to the ability of the DBUH/DLAH/DTLH to accept differing module types into it, the module status request reply

may vary between these different channel types.

Instruction 22 (System Reconfiguration Requests)

The unit MUST be in remote mode to allow reconfiguration of parameters via the remote control. Setting the unit in

Remote mode can be done either by the front panel or remotely using the instruction 24.

This message should only be used with units with the mute option fitted.

Instruction 24 (Set Remote/Local Mode)

Message

Byte No.

Set Value /

(example)

Length

(bytes)

Description

1

02

1

STX

2

?

1

No of bytes in message

3

?

1

Address

4

20

1

Message instruction

5

‘R’

1

‘R’ = Remote Mode

‘L’ = Local Mode

6

?

1

Checksum

7

03

1

ETX

Message

Byte No.

Set Value /

(example)

Length

(bytes)

Description

1

02

1

STX

2

?

1

No of bytes in message

3

?

1

Address

4

22

1

Message instruction

5

‘M’

1

Module

6

‘01’

2

Module number

8

‘+123’

4

Attenuation in 0.1 dB steps

‘+123’ = 12.3dB

12

?

1

Checksum

13

03

1

ETX

Message

Byte No.

Set Value /

(example)

Length

(bytes)

Description

1

02

1

STX

2

?

1

No of bytes in message

3

?

1

Address

4

22

1

Message instruction

5

‘S’

1

System

6

‘M’

1

Wanted mute status

‘U’ = Unmuted

‘M’ = Mute

7

?

1

Checksum

8

03

1

ETX

Issue 3.20 DBUH / DLAH / DTLH Installation and Operation Handbook Page 19

Instruction 40 (Unit Status Request)

Message

Byte No.

Set Value /

(example)

Length

(bytes)

Description

1

02

1

STX

2

?

1

No of bytes in message

3

?

1

Address

4

40

1

Message instruction

5

?

1

Checksum

6

03

1

ETX

Instruction 41 (Unit Status Request Reply)

Message

Byte No.

Set Value /

(example)

Length

(bytes)

Description

1

02

1

STX

2

?

1

No of bytes in message

3

?

1

Address

4

41

1

Message instruction

5

‘ DLAH200’

27

Type of unit this is: DLAH200 etc

32

‘12345’

5

Serial Number

37

’0112.34’

7

Software Version Number

44

‘0’

1

Summary Alarm OK/FAULT

‘0’ = OK ‘1’ = FAULT

45

‘0’

1

+5V voltage out of range fault

‘0’ = OK ‘1’ = FAULT

46

‘0’

1

-15V voltage out of range fault

‘0’ = OK ‘1’ = FAULT

47

‘0’

1

Temperature out of range fault

‘0’ = OK ‘1’ = FAULT

48

‘0’

1

Internal Communications Fault

‘0’ = OK ‘1’ = FAULT

49

‘0’

1

Coax Switch Fault

‘0’ = OK ‘1’ = FAULT

50

‘0’

1

Ethernet Module Fault

‘0’ = OK ‘1’ = FAULT

51

‘0’

1

Mute Switch Fault

‘0’ = OK ‘1’ = FAULT

52

‘….’

4

NOT USED

56

‘23/12/02 12:34:56’

17

OK Since time/date string, if there is a fault

with this down/up part of the converter

then the string is blank.

73

‘0’

1

Remote mode

‘0’ = Local ‘1’ = Remote

74

?

1

Checksum

75

03

1

ETX

Issue 3.20 DBUH / DLAH / DTLH Installation and Operation Handbook Page 20

Instruction 42 (Internal Redundancy Status Request):

Message

Byte No.

Set Value /

(example)

Length

(bytes)

Description

1

02

1

STX

2

?

1

No of bytes in message

3

?

1

Address

4

42

1

Message instruction

5

?

1

Checksum

7

03

1

ETX

Instruction 43 (Internal Redundancy Status Request Reply):

Instruction 44 (Module Reconfiguration Requests)

The unit MUST be in remote mode to allow reconfiguration of parameters via the remote control. Setting the unit in

Remote mode can be done either by the front panel or remotely using the instruction 24.

If the user is requiring the redundancy mode to be Automatic then the ‘Module to be forced online’ parameter in the

message above is ignored.

Message

Byte No.

Set Value /

(example)

Length

(bytes)

Description

1

02

1

STX

2

?

1

No of bytes in message

3

?

1

Address

4

43

1

Message instruction

5

(‘M’)

1

Redundancy Mode

‘M’ = Manual

‘A’ = Auto

6

(‘1’)

1

Unit Online

‘1’ = Module 1 Online

‘2’ = Module 2 Online

‘?’ = Unknown due to Coax Switch error

7

(‘1’)

1

Copy Settings across from one module to

another when switching

‘0’ = No ‘1’ = Yes

8

(‘1’)

1

Wanted Module Online, i.e. which module

was asked to be forced online

‘1’ or ‘2’

9

?

1

Checksum

10

03

1

ETX

Message

Byte No.

Set Value /

(example)

Length

(bytes)

Description

1

02

1

STX

2

?

1

No of bytes in message

3

?

1

Address

4

44

1

Message instruction

5

(‘M’)

1

Redundancy Mode

‘M’ = Manual

‘A’ = Auto

6

(‘1’)

1

Copy Settings across from one module to

another when switching

‘0’ = No ‘1’ = Yes

7

(‘1’)

1

Module To be Forced Online

‘1’ or ‘2’

8

?

1

Checksum

9

03

1

ETX

This manual suits for next models

3

Table of contents

Other PEAK COMMUNICATIONS Media Converter manuals

Popular Media Converter manuals by other brands

Baumer

Baumer Hubner Berlin HMG 11 Mounting and operating instructions

Itel

Itel STL-SAT Changeover user manual

SWIT

SWIT S-4612 user manual

Advantech Wireless

Advantech Wireless SSPBMg-C400-BRE Installation and operating manual

EnvironmentalLights.com

EnvironmentalLights.com DMX 512 PixelControl manual

Clarity

Clarity U-PAD2 manual

RKC INSTRUMENT

RKC INSTRUMENT COM-K IMR01Z01-E9 instruction manual

Baumer

Baumer HUBNER BERLIN DeviceNet PMG 10 Installation and operating instructions

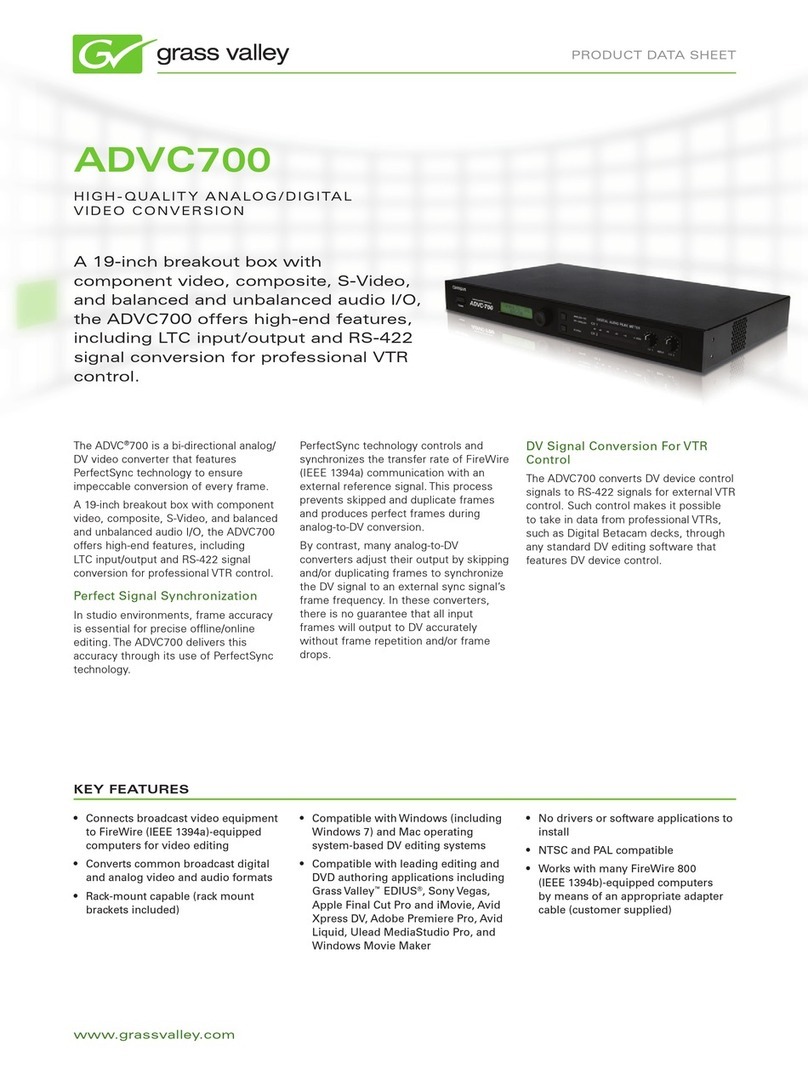

GRASS VALLEY

GRASS VALLEY ADVC700 - datasheet

DENAFRIPS

DENAFRIPS Terminator manual

AV Access

AV Access 4KIP200 user manual

Becker

Becker VAU 1.1/1-AC operating instructions