1 Introduction

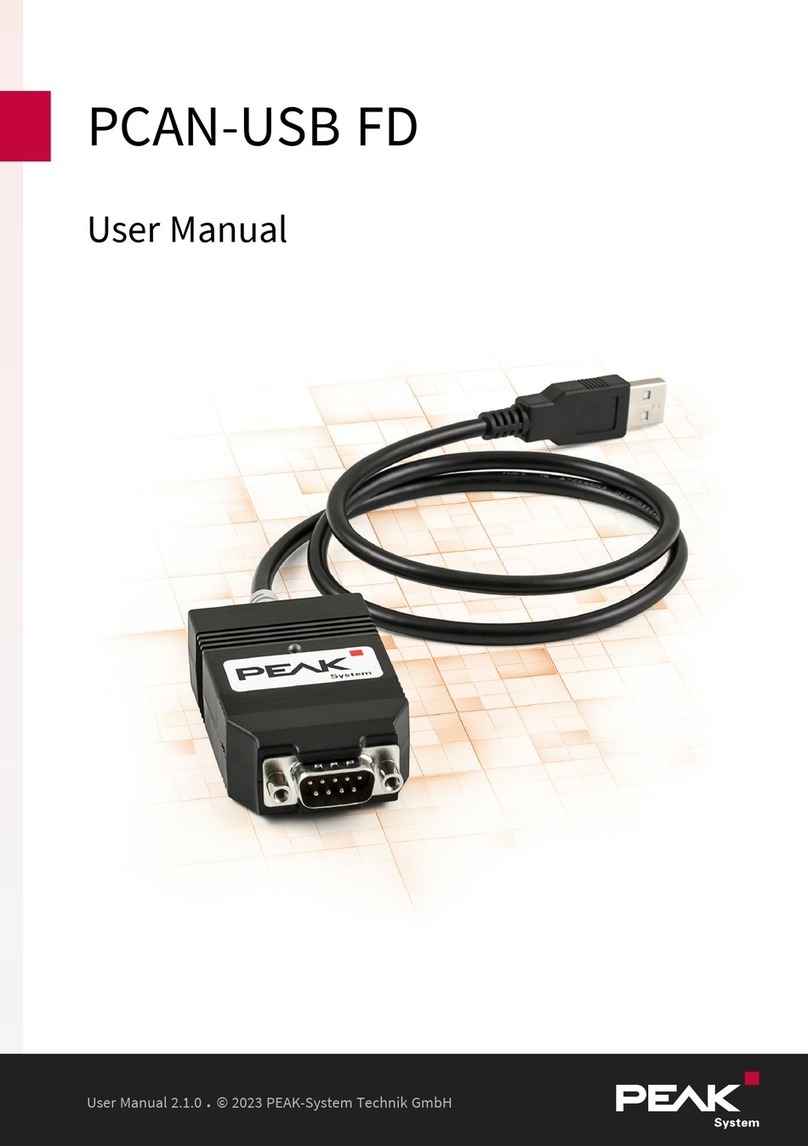

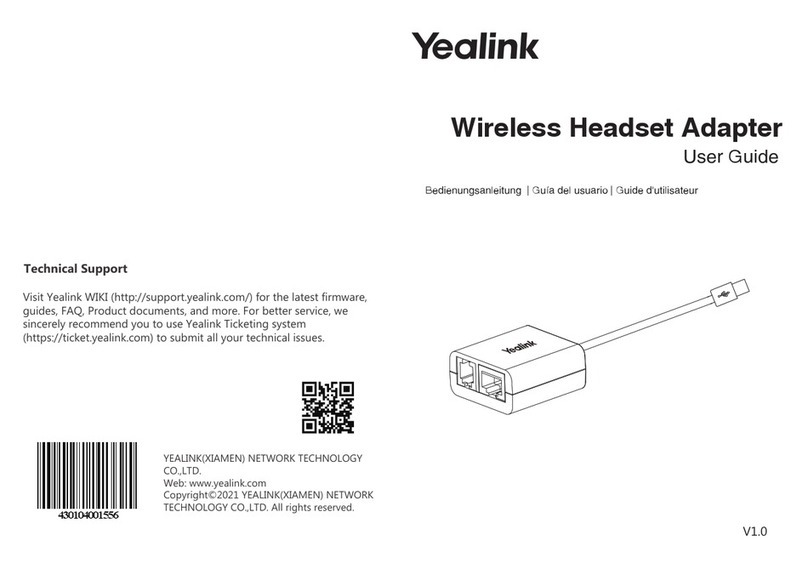

The PCAN-USBProFD interface enables the connection of CAN FD and LIN

networks to a computer via USB. Two field buses can be connected at the same

time, up to four with appropriate adapter cables (2 x CAN FD, 2 x LIN). Each CAN FD

channel is separately isolated against USB and LIN with a maximum of 500 Volts. Its

robust aluminum casing makes the PCAN-USBProFD interface suitable for mobile

applications.

The CAN FD standard (CAN with Flexible Data rate) is primarily characterized by

higher bandwidth for data transfer. The maximum of 64 data bytes per CAN FD

frame (instead of 8 so far) can be transmitted with bit rates up to 12 Mbit/s. CAN FD

is downward compatible to the CAN 2.0 standard, CAN FD nodes can be inserted

into already existing CAN networks without CAN FD extensions.

The monitor software PCAN-View and the programming interface PCAN-Basic for

the development of applications with CAN connection are included in the scope of

supply and support the standard CAN FD. The monitor application PLIN-View Pro as

well as the PLIN programming interface are also included in the scope of supply.

This manual describes the use of the CAN interface with Windows.

CAN device drivers and application information for Linux:

www.peak-system.com/quick/DL-Driver-E

At the end of this manual you can find a Quick Reference with brief

information about the installation and operation of the interface.

1 Introduction PCAN-USBProFD

User Manual 2.0.0 © 2023 PEAK-System Technik GmbH

5