1 Introduction

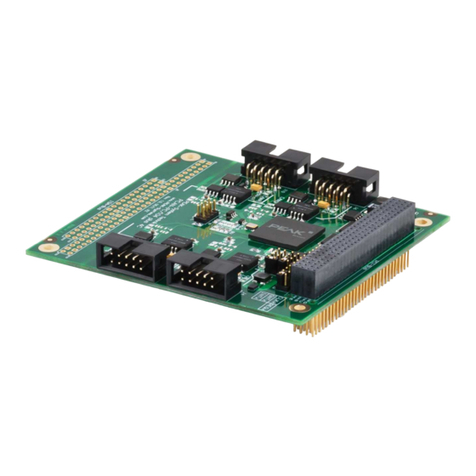

This product is an evaluation board for the PCAN-MicroMod FD and allows the concep-

tion and development of own circuits with CAN connection and I/O functionality. It

can also be used for training purposes for CAN and CAN FD setups. Via pick-offs,

screw terminals, switches, and potentiometers, the user can access the resources of

the attached PCAN-MicroMod FD and check configurations or test circuits.

The configuration is done with a supplied Windows software which transfers the

configuration data to the module via CAN. The optionally available Evaluation Kit

includes the CAN interface and a CAN cable required for this purpose.

This document describes the hardware and functions of the Evaluation Board. A

separate document is available for the plug-in board PCAN-MicroMod FD itself.

1.1 Features Overview

Screw terminal connectors for all I/Os

CAN bus connection via D-Sub, 9-pin (in accordance with CiA®303-1)

Switchable CAN termination of 120 Ohm

Pick-offs for all pins of the PCAN-MicroMod FD

Low-side switches for the digital outputs

DIP switches for status change of the digital inputs

Protected digital inputs

LEDs for digital inputs and outputs

4 potentiometers for analog inputs

Soldering fields for individual additional wiring

RS-232 connection with V.24 signal levels for direct access to the microcontroller

4-bit rotary coding switch for setting the module ID

1 Introduction PCAN-MicroMod FD EvaluationBoard

User Manual 1.1.0 © 2020 PEAK-System Technik GmbH

5