1

Contents

Owner’s Product Identification .............................................2

Important Information ...................................................3

Scope and Purpose of This Manual ...................................................3

Intended Use of Product............................................................3

Safety Instructions ................................................................3

Explanation of Safety Symbols and Notes ..............................................4

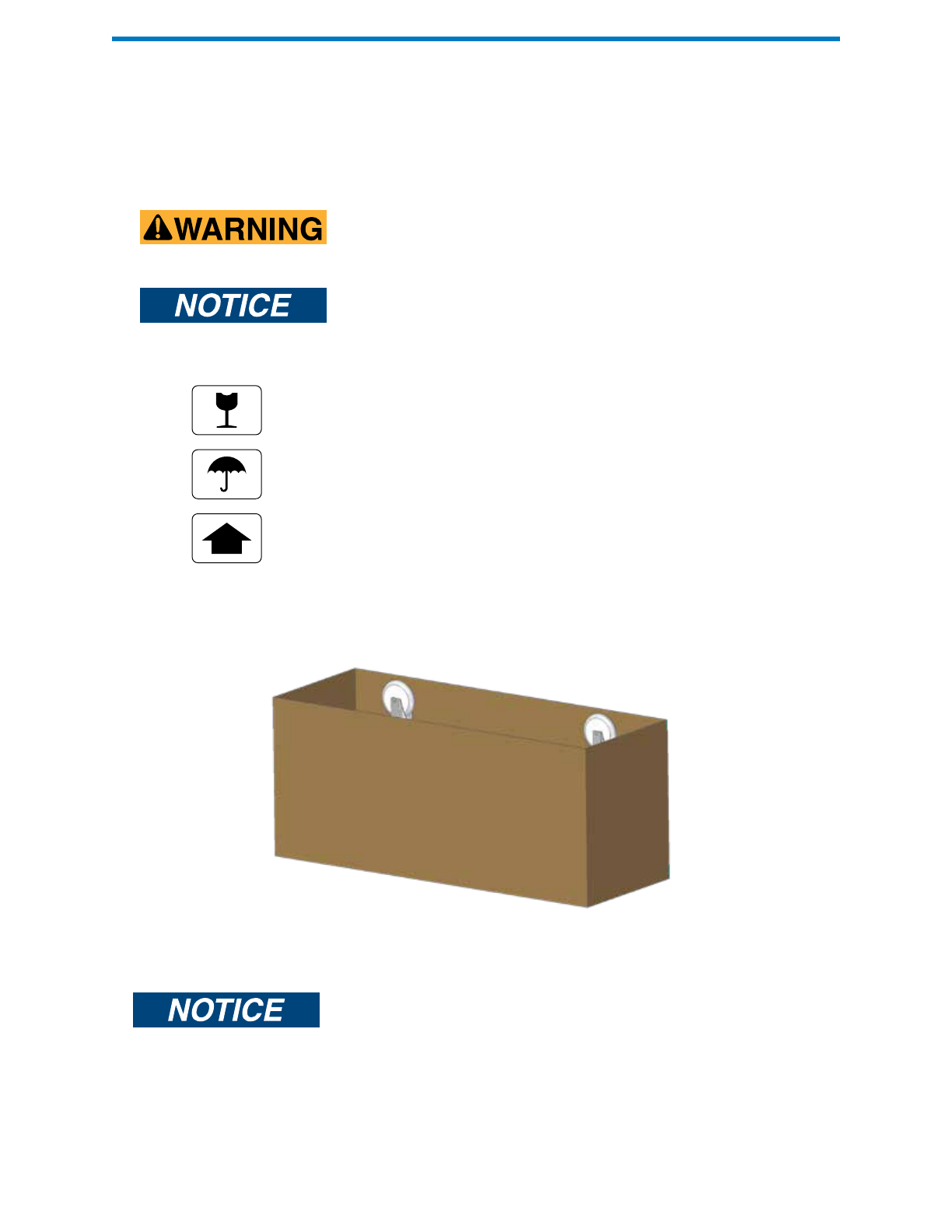

Transportation and Storage Conditions ................................................4

Installation ............................................................5

Unpacking ......................................................................5

Description ...........................................................6

Introduction .....................................................................6

Features........................................................................6

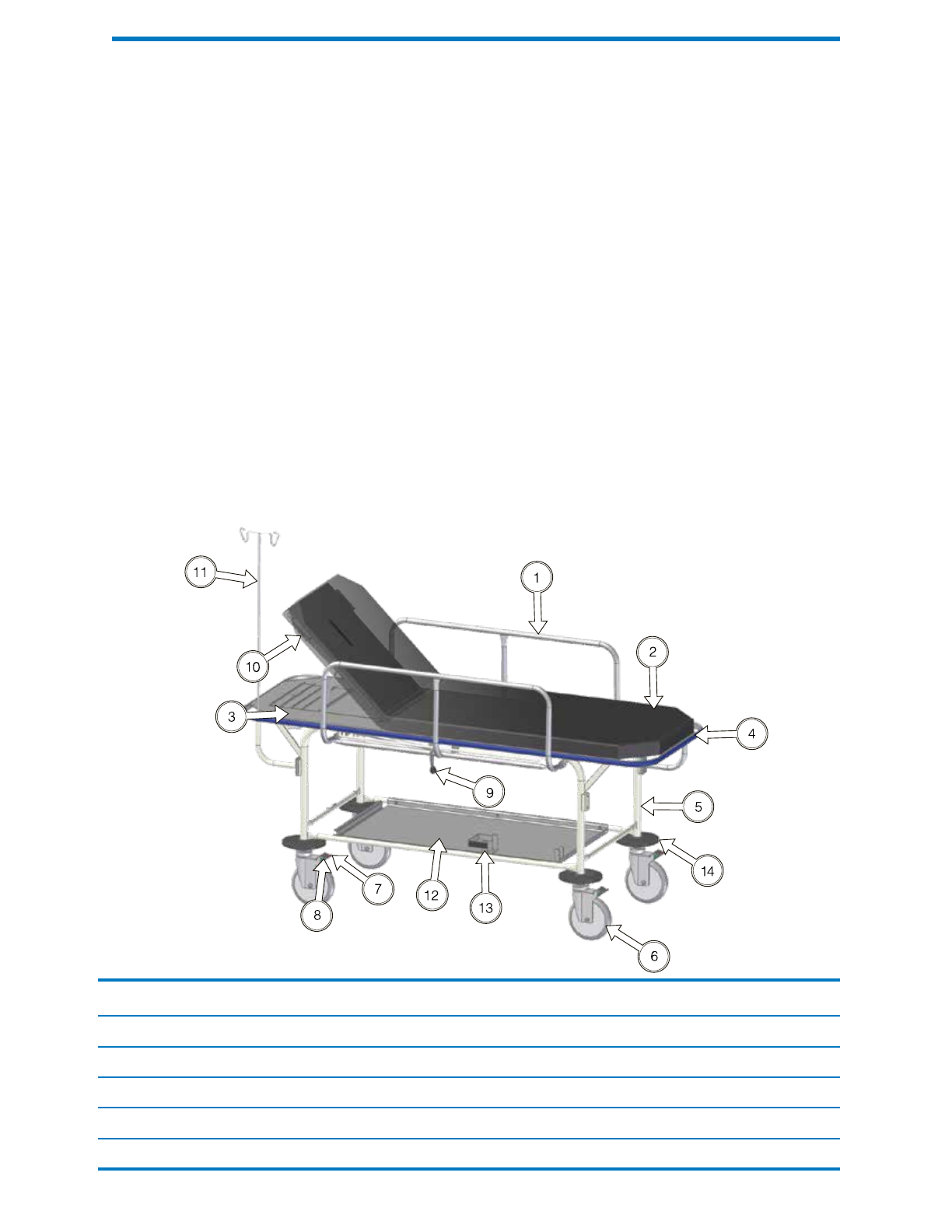

Components Overview ..................................................6

Controls and Indicators ..................................................7

Checklist of Installed Options & Authorized Accessories .........................8

Stretcher Operation .....................................................9

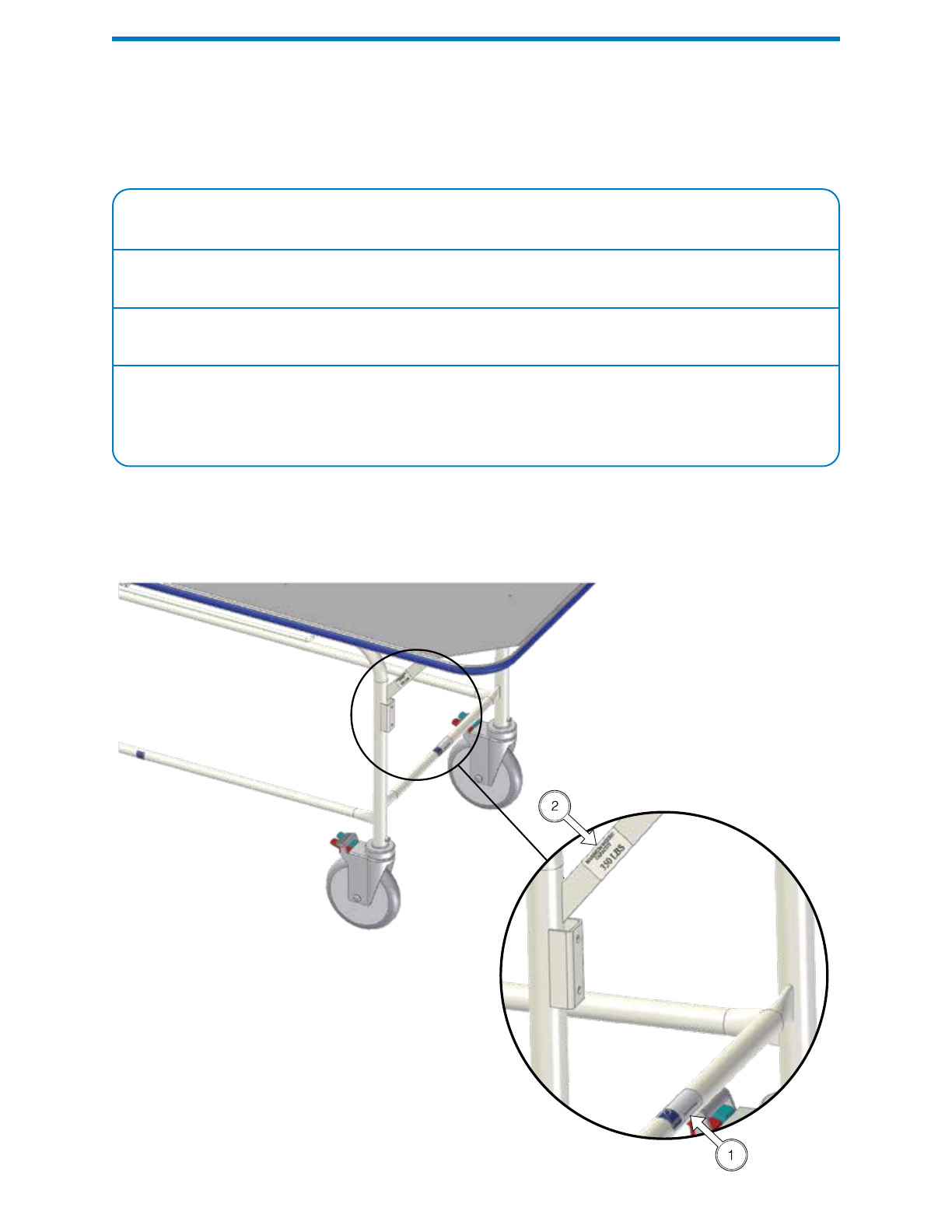

Braking and Steering Controls .......................................................9

Side Rails (Option) ...............................................................10

Fowler Section Positioning (Option) ..................................................11

Locating Sockets for I.V. Poles (Option) ...............................................12

Maintenance .........................................................13

Cleaning.......................................................................13

Preventive Maintenance...........................................................14

Scheduled Maintenance ..........................................................15

Calling for Service .....................................................15

Specifications ........................................................16

Limited Warranty ......................................................17