* Use the authorized service and parts manual for a particular product before you attempt repairs or adjustments.

** Optional equipment for Model 500,

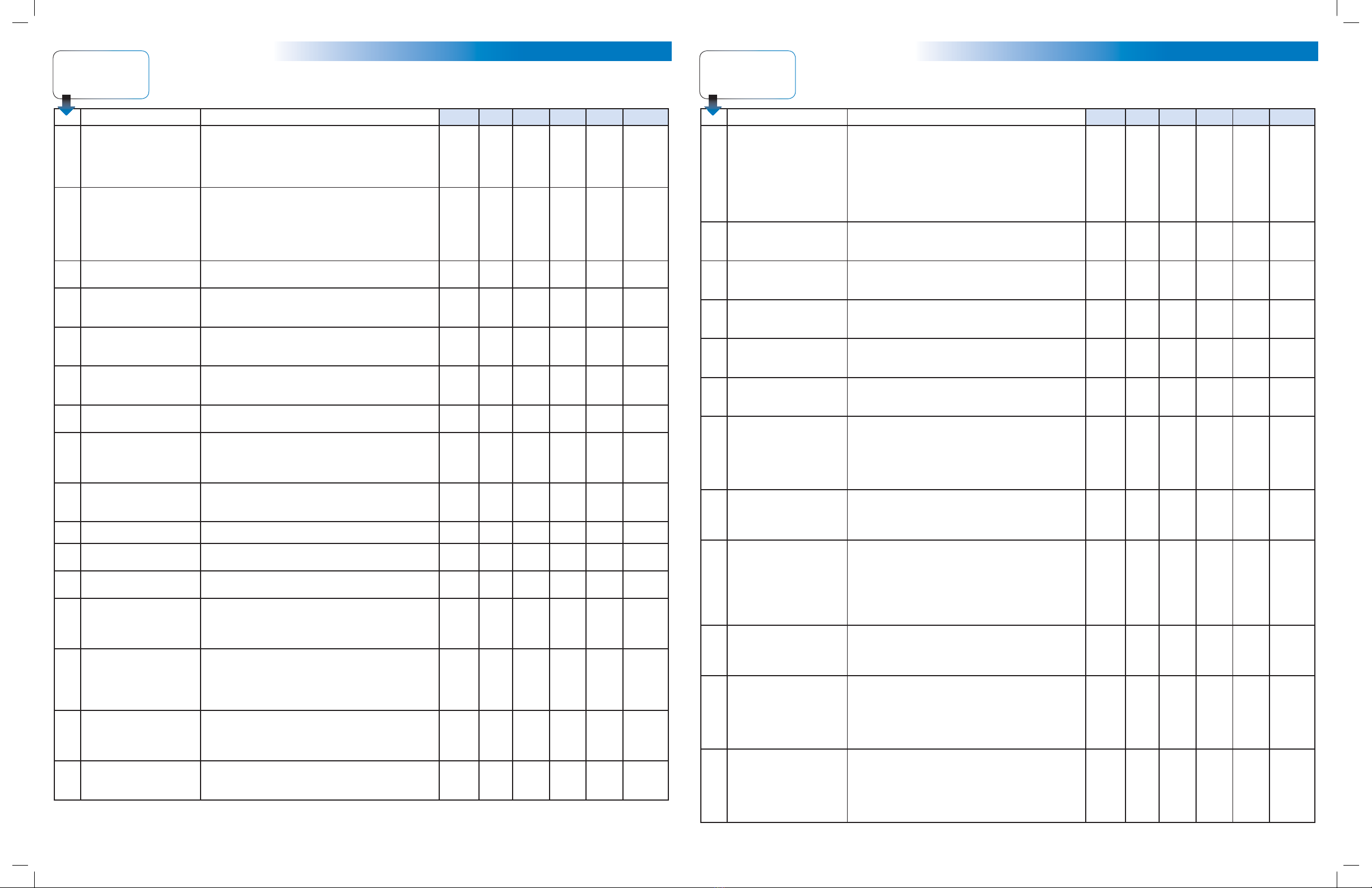

Inspection or Service Action* P-170 500 5110 5400 7500 7500NE

DUpholstery Wipe with a clean damp cloth or sponge. Use mild

soap and water solution for hard-to-clean areas and

stained areas. If disinfectant cleaners are used, do not

exceed manufacturer’s recommended dilution rate or

life expectancy of upholstery may be shortened.

99999 9

DObvious damage Visually check condition of stretcher/crib for obvious

damage: cracks in components, missing components,

dents in components, torn upholstery, leaking fluids, or

any other visible damage which would cause stretcher/

crib to be unsafe for usage. Repair stretcher/crib before

using

99999 9

DPainted metal and

plastic surfaces

Wipe with a clean soft damp cloth. 99999 9

DUnpainted metal and

chromed surfaces

Wipe with a clean soft damp cloth. Check all metal

surfaces for dents or damage that could result in sharp

edges. Replace damaged metal.

99999 9

DSecurity Top (plastic)** Wipe with a clean cloth or sponge dampened with a

nonabrasive cleaning solution. Be careful not to scratch

the plastic surface

9

DElevation column

bellows cover

Check bellows cover for rips, tears, or other obvious

damage. Repair or replace bellows cover if damaged.

Ensure that velcro restraints or closures are intact.

999 9

DRestraint Straps** Check restraint straps for fraying, rips, and proper

operation. Replace restraint straps if necessary 99999

DFasteners / hardware Check stretcher/crib for missing or loose fasteners/

hardware. Replace any missing hardware and tighten

any loose hardware as necessary using removable

threadlock if applicable.

99999 9

S-A Moving parts Lubricate with lithium white grease or petroleum jelly,

except linkages, which should be lubricated with Teflon

or Silicon based lubricant.

99999 9

S-A Caster pedal labels If labels are missing, replace as necessary. 999 9

S-A Warning & instructional

decals

Check for missing or illegible decals. Replace warning

and instructional decals as necessary. 99999 9

S-A Siderail slide area Lubricate the siderail slide area with mineral oil or food-

grade Silicon. 9

S-A Siderail operation Check for proper siderail operation, making sure that

siderails release and latch easily. Adjust siderails if

necessary. Adjust or repair latching mechanism if

necessary.

99999 9

S-A Siderail pivot points Lubricate siderail pivot points with Teflon or Silicon

based lubricant. Check that pivot points move freely

during operation of side rails. Repair pivot points if

necessary. If bolts/nuts are loose, remove bolts/nuts,

apply removable threadlock and reinstall bolts/nuts

99999

S-A Siderail latch mechanism Lubricate latch mechanism with lithium white grease or

petroleum jelly. Check that latch mechanism releases

and latches easily. Adjust or repair latch mechanism if

necessary.

99999

S-A Caster stem screws Check caster stem screws for tightness. Remove any

loose screws, apply removable threadlock, and reinstall

screws and lockwashers.

99999 9

The columns listed below are the model numbers of all

Pedigo stretchers / cribs and denote which inspections

and services apply to each model.

Legend

D= Daily

S-A = Semi-Annually Scheduled Maintenance

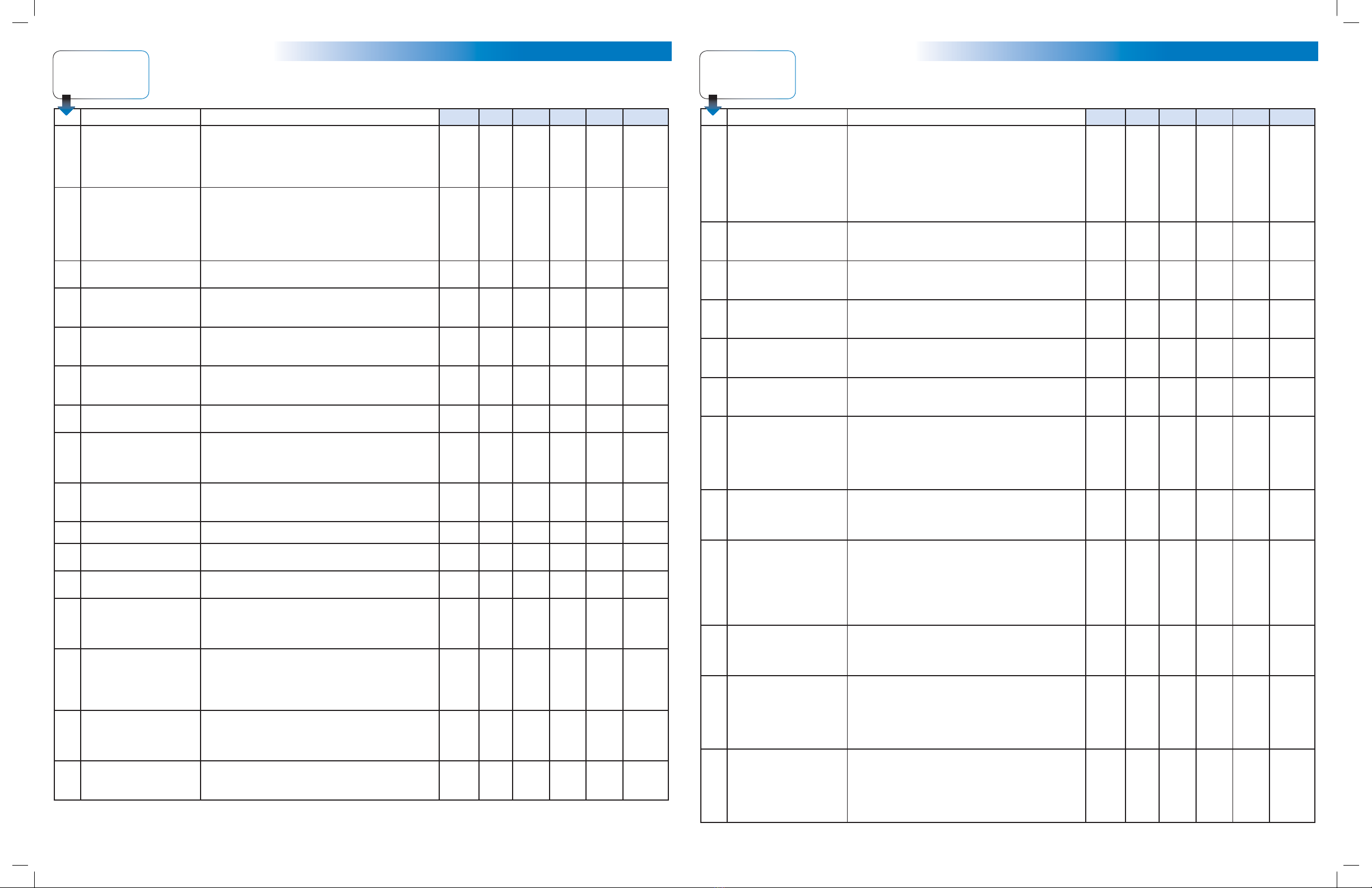

Inspection or Service Action* P-170 500 5110 5400 7500 7500NE

S-A Caster control pedal Check control pedals for proper operation. Make

sure all pedals work in the brake, neutral, and steer

positions. Brake engaged (red pedal down): Check

that all four wheels of stretcher will not move when

brake is engaged. Neutral (pedal in close to horizontal

position): Check that all four wheels operate in free

wheel when neutral is engaged. Steer engaged (green

pedal down):

999 9

S-A TDS True Direction

Steering

Check that steer casters lock in forward and reverse

positions when steer is engaged. Adjust or repair any

of the pedals as necessary

99

S-A IS6 Instant Six Wheel

Steering

Check both steering wheels contact floor when

steering engaged. Adjust or repair any of the pedals

as necessary

99 9

S-A Elevation pump pedal(s) Check elevation cylinder pedals for firmness. Check

that stretcher. Litter top lowers when pump pedal is

raised.

99 9

S-A Hydraulic elevation pump Check hydraulic pump for leaks. If stretcher does not

have full travel or release properly, contact Pedigo

customer service.

99 9

S-A Elevation post pins Check elevation post nuts/bolts for looseness. If loose,

replace bolts and nuts with new bolts and nuts using

removable threadlock on bolt threads

9

S-A Fowler cylinder and

linkage

Lubricate linkage of fowler cylinder with Teflon or Silicon

based lubricant. Check fowler cylinder and linkage for

proper operation, alignment, and engagement. Make

sure cylinder releases and holds. Adjust linkage

if necessary. Replace fowler cylinder if it does not

operate correctly.

999 9

S-A Linkage for manual Fowler

operation**

Lubricate fowler linkage with Teflon or Silicon based

lubricant. Check fowler linkage for proper operation,

alignment, and engagement. Repair fowler linkage if

necessary.

9

S-A Trendelenburg cylinder

and linkage

Lubricate linkage of trendelenburg cylinder with Teflon

or Silicon based lubricant. Check trendelenburg

cylinder and linkage for proper operation, alignment,

and engagement. Make sure cylinder releases, holds,

and level locks (if applicable) properly. Adjust linkage

if necessary. Replace trendelenburg cylinder if it does

not operate correctly.

999 9

S-A Linkage for manual

Trendelenburg operation

(optional equipment for

Model 500)

Lubricate trendelenburg linkage with Teflon or Silicon

based lubricant. Check trendelenburg linkage for

proper operation, alignment, and engagement.

Repair trendelenburg linkage if necessary.

9

S-A Headrest cylinder linkage Lubricate linkage of headrest cylinder with Teflon

or Silicon based lubricant. Check headrest cylinder

and linkage for proper operation, alignment, and

engagement. Make sure cylinder releases and holds.

Adjust linkage if necessary. Replace headrest cylinder

if it does not operate properly.

9

S-A Wrist rest pivot points Lubricate wrist rest pivot points with Teflon or Silicon

based lubricant. Check that pivot points move freely

during operation of the wrist rest.

Repair pivot points if necessary. If bolts / nuts are loose,

remove bolts / nuts, apply removable threadlocking

adhesive and reinstall bolts / nuts.

9

The columns listed below are the model numbers of all

Pedigo stretchers / cribs and denote which inspections

and services apply to each model.

Legend

D= Daily

S-A = Semi-Annually Scheduled Maintenance

7HENCALLING0EDIGOPLEASEHAVETHEMODELNUMBERANDSERIALNUMBERFORTHEUNITSsORFAX