VITALI T5 User manual

T5 Re-Rm

Technician

EN

1

T5

CONTENTS

1 MANUFACTURER’S NOTES ON INSTALLATION ............................................................................................................................... 2

2 WARRANTY .................................................................................................................................................................................. 3

Circumstances not covered by warranty ................................................................................................................................................................ 3

3SYMBOLS USED ............................................................................................................................................................................ 5

4TECHNICAL SPECIFICATIONS ......................................................................................................................................................... 6

5FLARES CHAIR CONNECTION TEMPLATE ....................................................................................................................................... 6

6OVERALL DIMENSIONS ................................................................................................................................................................. 7

7INSTALLATION INSTRUCTIONS ...................................................................................................................................................... 8

Assembling the backrest ........................................................................................................................................................................................ 9

Assembling the backrest housing ........................................................................................................................................................................ 10

Mounting the dental unit bracket on the chair .................................................................................................................................................... 11

Assembling the water unit ................................................................................................................................................................................... 12

Assembling the instrument table arm .................................................................................................................................................................. 13

Assembling the tray table .................................................................................................................................................................................... 14

Grounding connection for water unit - dental unit bracket - instrument table arm ................................................................................................ 15

Water unit electrical connection .......................................................................................................................................................................... 15

Assembling the instrument table ......................................................................................................................................................................... 16

Hydraulic and pneumatic connections for the instrument table............................................................................................................................ 17

Electrical connections for the instrument table ..................................................................................................................................................... 19

Bowl suction and flushing connection ................................................................................................................................................................. 20

Hydraulic connection for water unit .................................................................................................................................................................... 20

Hydraulic and pneumatic connections to the connector block ............................................................................................................................. 21

Assembling the (optional) suction tube support arm and grounding connection .................................................................................................. 22

Setting the FLARES chair movement Dip-Switches ................................................................................................................................................ 23

8INSTALLATION INSPECTION ........................................................................................................................................................ 24

9SERIAL NUMBER LOCATION ........................................................................................................................................................ 25

10 ACCESSING THE INTERNAL PARTS - FLARES ................................................................................................................................. 26

Removing the derivative housing ........................................................................................................................................................................ 26

Removing seat upholstery ................................................................................................................................................................................... 27

Installing seat upholstery ..................................................................................................................................................................................... 27

Removing the coplanar headrest upholstery ........................................................................................................................................................ 28

Removing the double-jointed headrest upholstery ............................................................................................................................................... 28

Removing the backrest upholstery ....................................................................................................................................................................... 28

Removing the seat housing ................................................................................................................................................................................. 29

Disassembling the headrest bracket ..................................................................................................................................................................... 29

Removing the fixed armrest ................................................................................................................................................................................. 30

Removing the tilting armrest (optional) ................................................................................................................................................................ 30

Removing the lower parallelogram housing ........................................................................................................................................................ 31

Removing the upper parallelogram housing ........................................................................................................................................................ 31

11 FLARES ELECTRICAL UNIT ........................................................................................................................................................... 32

Replacing fuses ................................................................................................................................................................................................... 33

12 ACCESSING INTERNAL PARTS OF THE WATER UNIT ..................................................................................................................... 34

Available versions of the water unit ..................................................................................................................................................................... 36

13 PRESSURIZED BOTTLE KIT ........................................................................................................................................................... 37

Operating diagram of the pressurized bottle ....................................................................................................................................................... 38

14 DENTAL UNIT ELECTRICAL GROUP .............................................................................................................................................. 39

Setting the dental unit card dip-switches ............................................................................................................................................................. 40

Replacing the dental unit card fuses .................................................................................................................................................................... 40

15 ACCESSING THE INTERNAL PARTS OF THE INSTRUMENT TABLE .................................................................................................. 41

16 INSTRUMENT SELECTION CARD .................................................................................................................................................. 43

Electronic card fuses ............................................................................................................................................................................................ 43

17 ACCESSING THE INTERNAL PARTS OF THE ASSISTANT CONSOLE ................................................................................................. 44

Electrical connections for the assistant console .................................................................................................................................................... 46

18 HYDROPNEUMATIC ADJUSTMENTS ............................................................................................................................................. 47

Adjusting and setting the table instruments ......................................................................................................................................................... 48

Hydropneumatic diagram ................................................................................................................................................................................... 50

19 KEYPAD FUNCTIONS ................................................................................................................................................................... 51

20 ASSISTANT CONSOLE .................................................................................................................................................................. 53

Assistant/patient keypad functions (located on console) ....................................................................................................................................... 53

21 VITALI FOOT CONTROLS ............................................................................................................................................................. 54

Electronic foot control ......................................................................................................................................................................................... 54

Electronic foot control setting and configuration ................................................................................................................................................. 55

Two-lever foot control ......................................................................................................................................................................................... 56

22 SAFETY DEVICES ......................................................................................................................................................................... 57

23 SPECIAL MAINTENANCE ............................................................................................................................................................. 59

Replacing the vertical chair movement gearmotor ............................................................................................................................................... 59

Replacing the backrest actuator ........................................................................................................................................................................... 60

Adjusting the backrest movement cradle friction .................................................................................................................................................. 61

Adjusting the backrest movement mechanical memory ....................................................................................................................................... 62

Adjusting the vertical chair movement mechanical memory ................................................................................................................................. 62

Adjusting the instrument table support panel friction ........................................................................................................................................... 63

Assembling the table instrument cords ................................................................................................................................................................ 64

Replacing the bowl ............................................................................................................................................................................................. 64

Assembling the instrument table arm stop ........................................................................................................................................................... 65

Assembling the instrument table arm .................................................................................................................................................................. 65

24 MAINTENANCE ........................................................................................................................................................................... 66

Disinfecting ........................................................................................................................................................................................................ 67

Autoclavable parts .............................................................................................................................................................................................. 68

25 PERIODIC CHECKS ...................................................................................................................................................................... 69

Turbine lubrication oil recovery device ................................................................................................................................................................. 70

Checking the backrest protection brush ............................................................................................................................................................... 71

Checking the pull spools ..................................................................................................................................................................................... 71

Checking for wear on the gearmotor winding block ........................................................................................................................................... 72

Replacement of the cannula terminals and external suction hoses ....................................................................................................................... 73

Checking the internal suction hoses .................................................................................................................................................................... 73

Replacing the water unit filters ............................................................................................................................................................................ 73

Replacing the air unit filter .................................................................................................................................................................................. 74

26 REQUESTING SPARE PARTS AND MATERIALS ............................................................................................................................... 75

27 WIRING DIAGRAMS .................................................................................................................................................................... 77

T5

2

1 MANUFACTURER’S NOTES ON INSTALLATION

This technical manual, supplied to VITALI dealers, contains the information necessary in order to carry out

those tasks VITALI considers may be carried out by specially trained and authorized technical personnel.

VITALI may not be held liable for the safety, reliability or performance of the equipment if:

•installation, adjustments, changes or repairs have not been carried out by qualified dealer personnel;

•the electrical system of the room where the equipment is installed is not in compliance with current

regulations;

•the equipment is not used in accordance with the instructions.

The technical documentation supplied by VITALI along with the equipment contains all setting

instructions and other information that may be used by specially trained user personnel, to work on those

parts of the equipment that VITALI deems reparable by outside technicians.

VITALI declines all responsibility for personal injury or property damage derived from tampering by

unauthorized personnel, lack of or inadequate maintenance, the use of non-original spares or failure to

observe the instructions in the present manual.

This device must be used by qualified personnel only. VITALI shall not be liable for any direct or indirect

damages connected with improper uses or abuses of the equipment.

NOTE: The equipment is available in two versions, identified by different letter pairs

:

Re •Basic Version: includes manual chair controls (Optional: 1 working position definable during

installation).

Rm •Version with Memories: includes manual and automatic controls, definable by the user.

3

T5

2 WARRANTY

VITALI equipment is guaranteed ex works against defects in materials or workmanship for a period of twelve months

following installation.

Your VITALI Dealer will provide any repairs or replacements needed during the warranty period. Any repairs that

cannot be performed on-site will be carried out at authorized VITALI service centers. The customer will be charged

only for transport costs.

Circumstances not covered by warranty

The warranty shall not be upheld in the event of:

•installation was not duly carried out in accordance with the directions provided in the Installation Instructions;

•servicing has not been performed by qualified personnel authorised by VITALI;

•non-original spare parts have been used;

•the technical systems supplying the device (electricity, water, pneumatic supplies) have not been set up in

conformity with current technical standards and laws;

•supplementary equipment has been connected following the initial installation, exception being made for devices

authorised by VITALI;

•the operating and maintenance instructions contained in the documentation furnished by the manufacturer are

not complied with;

•the device identification label has been removed, erased or altered;

•the product displays damage caused by accidental impacts, faults or damage deriving from poor maintenance,

improper use or abuse of the equipment, improper supply systems, exposure to flames, spilling of liquids, natural

calamities, incompetence or any causes not ascribable to the manufacturer;

•the WARRANTY AND INSTALLATION CERTIFICATE has not been returned or registered by the user within 30 days

of the date of installation (or delivery). The user may also delegate the dealer to fulfil this requirement.

•The Warranty does not extend to ceramic parts, bulbs or any parts subject to wear or which have deteriorated

as a result of improper use or inadequate maintenance due to user negligence.

VITALI shall not be liable for inability to use the product caused by situations beyond its control, nor shall it be liable

for any damage incurred as a result of inability to use the product.

Any unauthorised servicing that results in an impairment of the essential safety features provided by the manufacturer

shall invalidate the CE DECLARATION OF CONFORMITY of the products.

Any parts to be replaced under warranty shall be returned to VITALI (together with the MAQ28 form) which shall

provide for shipment of the required spare part.

The Warranty does not provide for compensation of direct or indirect damages of any kind caused by eventual

defective equipment to people or things. VITALI shall freely decide whether to repair or replace defective products.

All products replaced or repaired under warranty shall be subject to a 6-month warranty, commencing from the

moment of repair or replacement.

Any spare parts sent under the clause “Anticipated replacement under warranty” shall be automatically invoiced

should the corresponding defective parts not be returned to Vitali within 15 days of the shipping date. For fiscal

reasons, spare parts shall be supplied under warranty provided Vitali has received the Certificate of Assembly and

Warranty containing all the client’s details.

The area dealer will be happy to provide you with any further information you may need.

T5

4

0476

è conforme ai requisiti essenziali di sicurezza della Direttiva 93/42/CE (D.Lgs.n.46/97) così come modificati dalla Direttiva 2007/47/CE (D.Lgs.n .37/2010)

complies with the essential safety requirements of the Directive 93/42/EC just as modified by the Directive 2007/47/EC

est conforme aux standards essentiels de sécurité de la Directive 93/42/CE ainsi que modifiés par la Directive 2007/47/CE

genauso der wesentlichen, wie von der Richtlinie 2007/47/EWG veränderten, Sicherheitsanforderungen der Richtlinie 93/42/EWG entspricht

FACSIMILE

5

T5

3 SYMBOLS USED

Activate spray instrument

Chip-Blower

Instrument on

Syringe water adjustment

Syringe air adjustment

Scaler water adjustment

Chip blower/spray air adjustment

Spray water adjustment

Scaler potentiometer

Instrument lighting brightness

adjustment

Micromotor rotation direction

reverse

Before disposal of waste produced during the use of the device or parts of the device itself, always carry out thorough

disinfection and ensure that all parts that are potentially subject to biological contamination are correctly packed.

Such parts must be disposed of in compliance with applicable national legislation and local bylaws.

The local VITALI Dealer will be glad to satisfy your queries on national and local laws on correct waste disposal.

Applicable only within EU countries

2002/96/EC Directive on Waste Electrical and Electronic Equipments (WEEE).

The symbol on the product means that, in the event of decommissioning, the device canot be disposed of as domestic waste, it must

instead be divided into its various component material types for sorted waste disposal.

The aim is to reduce the environmental impact of ANY electric or electronic equipment and minimize the volume of waste transported

to dumps. Correct disposal prevents potential damages to personal health and to the environment.

For this purpose, VITALI has complied with the obligations that statutory regulations place under the responsibility of the manufacturer.

The local VITALI Dealer will be able, if necessary, to give all information about.

The user can return the device to the manufacturer if a comparable device is purchased in its place. Improper disposal is punishable

by law.

Alternating current

Protective grounding

Type-B equipment

On / Off

General warning

Identification of manufacturer

Device serial number

Parts accessible with surface temperature

> 30 °C

Instrument function adjustment

Instrument rotation speed adjustment

Pressurized bottle

Pressurized bottle fluid level

Autoclavable device

Water mains

C

T5

6

4 TECHNICAL SPECIFICATIONS

This equipment must work in environments with a relative humidity between 45% and 75%, and with an

ambient temperature between 10 and 35 °C.

DENTAL UNIT

Model.......................................................................................................................................................... T5

Class (EN 60601-1) ................................................................................................................................. Class I

Class (Medical Devices Directive MDD) ................................................................................................. Class IIa

Protection rating ............................................................................................................................. Type B

Power supply............................................................................................................. 230 V 50-60 Hz 600 VA

Inlet air pressure ................................................................................................... min. = 5 bar ; max. = 10 bar

Inlet water pressure .............................................................................................. min. = 2 bar ; max. = 10 bar

Air minimum capacity ....................................................................................................................... 60 L/min.

Max. weight applicable to instrument tray .............................................................................................. 1,5 kg

Weight (Kg) ............................................................................................................................................ 40 kg

Filtering capability of suction filter ..................................................................................................... ø 0,8 mm

Filtering capability of bowl filter ......................................................................................................... ø 1,5 mm

Filtering capability of air filter.................................................................................................................. 20 μm

Filtering capability of water filter............................................................................................................. 80 μm

CHAIR

Modell ................................................................................................................................................ FLARES

Class (EN 60601-1) ................................................................................................................................. Class I

Protection rating .............................................................................................................................. Type B

Power supply............................................................................................................. 230 V 50-60 Hz 300 VA

Total weight ......................................................................................................................................... 127 Kg

Minimum seat height .............................................................................................................................. 45 cm

Maximum seat height ............................................................................................................................. 85 cm

Maximum seat width .............................................................................................................................. 50 cm

Total chair lift time .............................................................................................................................. ~ 15 sec

Total chair descent time ...................................................................................................................... ~ 15 sec

Total backrest lift time ......................................................................................................................... ~ 10 sec

Total backrest descent time ................................................................................................................. ~ 10 sec

☞WARNING! THE CORRECT OPERATING OF THIS EQUIPMENT DEPENDS ON THE

OBSERVANCE OF THE PARAMETERS ABOVE.

☞WARNING! THE EQUIPMENT IS NOT INTENDED FOR USE IN POTENTIALLY EXPLOSIVE

ATMOSPHERES (ATEX DIRECTIVE).

Ø 40.0

Ø 30.0

Ø 30.0

5 FLARES CHAIR CONNECTION TEMPLATE

SCALE 1:1

AIR

min. 5 Bar

max. 8 Bar

60 l/min.

COLD WATER

min. 2 Bar

max. 8 Bar

DENTAL UNIT DRAINAGE

FLARES CHAIR BASE PLATE

SEPARATOR

DRAINAGE

CENTRALIZED SUCTION

CONNECTION CONTROL

150 mm

365 mm

SUCTION

TUMBLER WITH TECHNICAL GASKET

FOR HOSE WITH OUTER DIAMETER 25

CONNECTION

AREA SECRETION SUCTION

PREPARE WITH TAPERED FITTING

FOR FLAT SPIRAL HOSE WITH INTERNAL DIAMETER 25

230 V AC 60 Hz

POWER SUPPLY

3/8 FITTING FOR 8x6 HOSE

TO BE EQUIPPED WITH CLOSING VALVE

3/8 FITTING FOR 8x6 HOSE

TO BE EQUIPPED WITH CLOSING VALVE AND

DE-COUPLER

USE 3 WIRES CROSS-SECTION 1.5 sqmm

MAIN ELECTRICAL POWER SUPPLY;

USE 3 WIRES CROSS SECTION 2.5 sqmm

DRAINAGE OF SECRETIONS FROM MINI-SEPARATOR

TO BE PREPARED ONLY

IF AIR RING SUCTION SYSTEM IS PRESENT

M12 LEVELING DOWEL

RUBBER PROTECTION

7

T5

6 OVERALL DIMENSIONS

Left-handed version Right version

T5

FLARES

13

85

45

176

62°

25°

SYNCHRONIZED TRENDELENBURG POSITION

90

°

R52 cm

90

°

97 cm

38 cm

176 cm

64 cm

80 cm

97 cm

133 cm 133 cm

178 cm

176 cm

64 cm

80 cm

R52 cm

R96 cm

178 cm

R96 cm

Connection area

62 cm

R56 cm

62 cm

R56 cm

SCALE 1:30

SCALE 1:20

T5

8

FB

A

D

E

GC

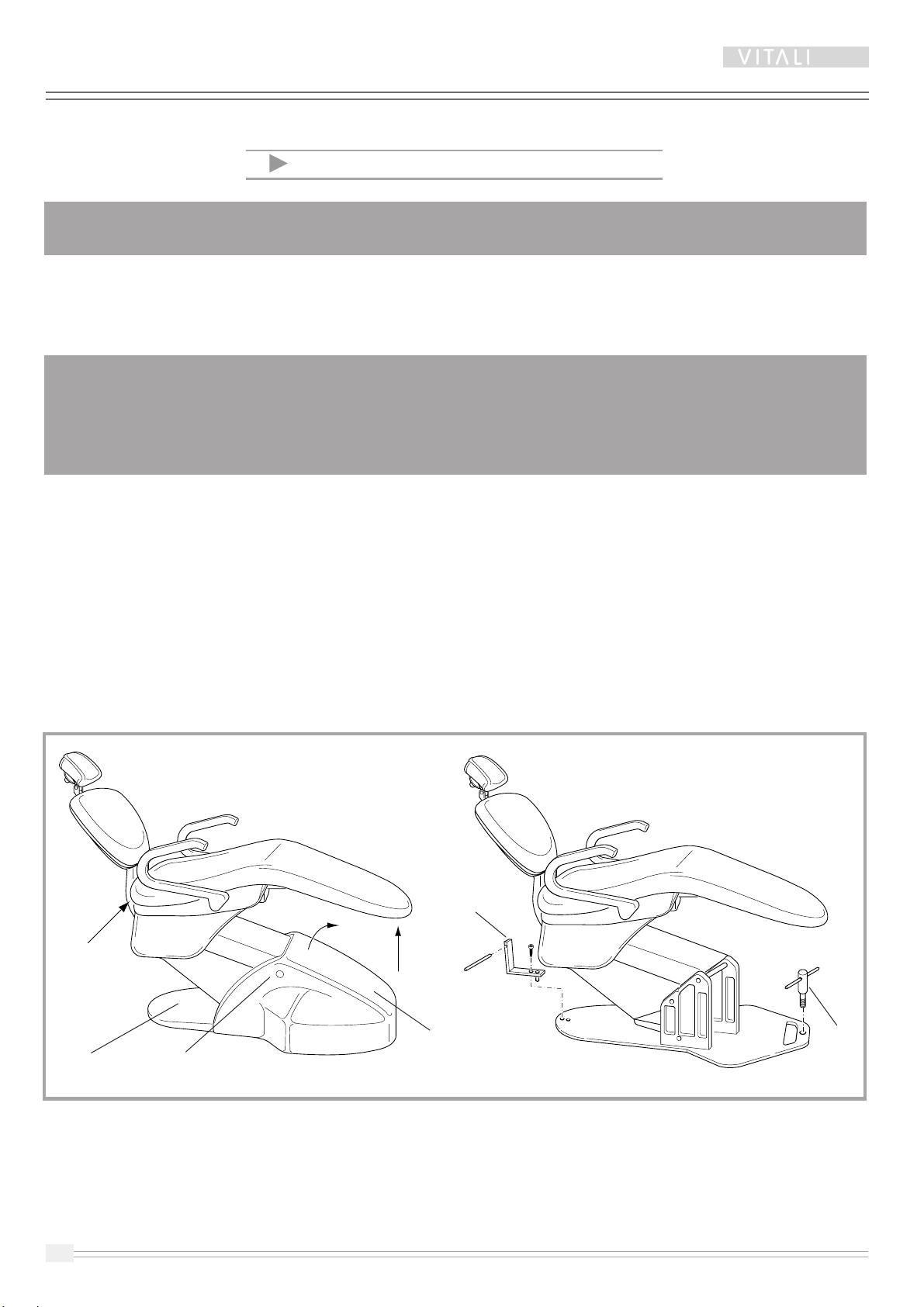

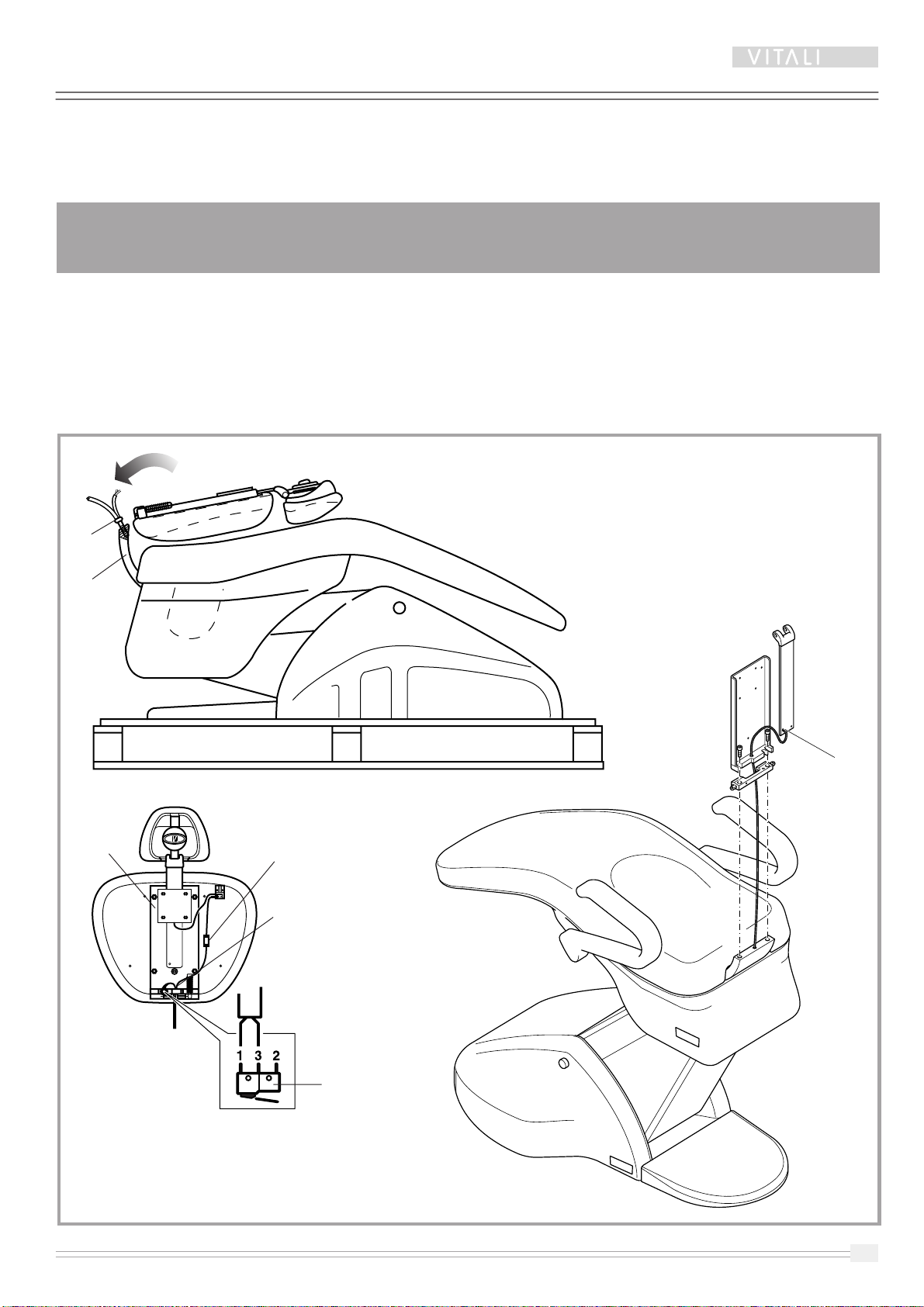

7 INSTALLATION INSTRUCTIONS

☞NOTE: For more details on removing the housing "F" and the seat upholstery, see the chapter on "Accessing

the internal parts - Flares".

PLEASE FOLLOW THE INSTRUCTIONS BELOW CAREFULLY

FOR INSTALLING THE FLARES CHAIR!

To avoid breaking the plastic housing, please use the special keys "A" and "B" supplied with the chair.

Use them as follows:

1) Power the chair at 230 V AC - 50/60 Hz - single-phase

WARNING!

The power supply cable should be directly connected to the electrical installation:

DO NOT make use of extension cables.

Each equipment have to be individually connected to a socket

through the provided plug, without using multiple outlets.

2) Press the main switch "C"

3) To raise the chair, use the foot control (if present) or dentist keypad, after connecting it to the connector CN20

of the chair card. In this case, see the chapter on "Setting the Chair Movement Dip-switches"

4) Remove the grey polyurethane cover "G" and tighten the key "A"

5) Remove the upholstery from the seat, pulling on points "D" and "E"

6) Remove the housing "F", after first turning the mobile part of the seat (see the chapter on "Accessing the

internal parts - Flares")

7) Tighten the key "B" in the point shown in the illustration

8) Move the chair by lifting it with the keys "A" and "B"

9) Remove the keys "A" and "B".

9

T5

Assembling the backrest

Proceed as follows to assemble the backrest:

1)

I

nsert the white Rilsan hose and electrical wires through the hole "H" on the base of the backrest frame "D"

2) Attach the backrest using the two M8 Allen screws "B" on the support "C"

3) Connect the white Rilsan hose to the quick fitting "E"

4) Connect the electrical cable to the microswitch "F" as shown in the illustration

5) Connect the grounding safety wire in point "G".

☞

NOTE: The Flares backrest is supplied disassembled and appropriately packed. During

installation, failure to correctly complete all of the connections shown will seriously

compromise the safety and proper operation of the equipment.

F

H

DE

B

C

G

T5

10

BB

Fig. 1 Fig. 2 Fig. 3

Backrest

structure

AC

A

D

Assembling the backrest housing

Proceed as follows to assemble the backrest housing:

1) Make sure the distance between the hooks "A" and the backrest structure is properly adjusted, to avoid

unnecessary strain when assembling the backrest upholstery, which could lead to breakage of the backrest

guard.

2) If necessary, correct the position of the hooks "A" by loosening the nuts "D". Tighten the nuts "D" when the

adjustment is complete

3) Tilt the backrest as shown in fig. 1 and fasten it using the hook "A". Pull downward until it is fully engaged with

the upholstery.

4) Fasten the guard in place using the two tapered screws "B" (fig. 2).

3) Finally, mount the headrest bracket release button "C" (fig. 3).

Perform the same steps in reverse order to remove the backrest housing.

11

T5

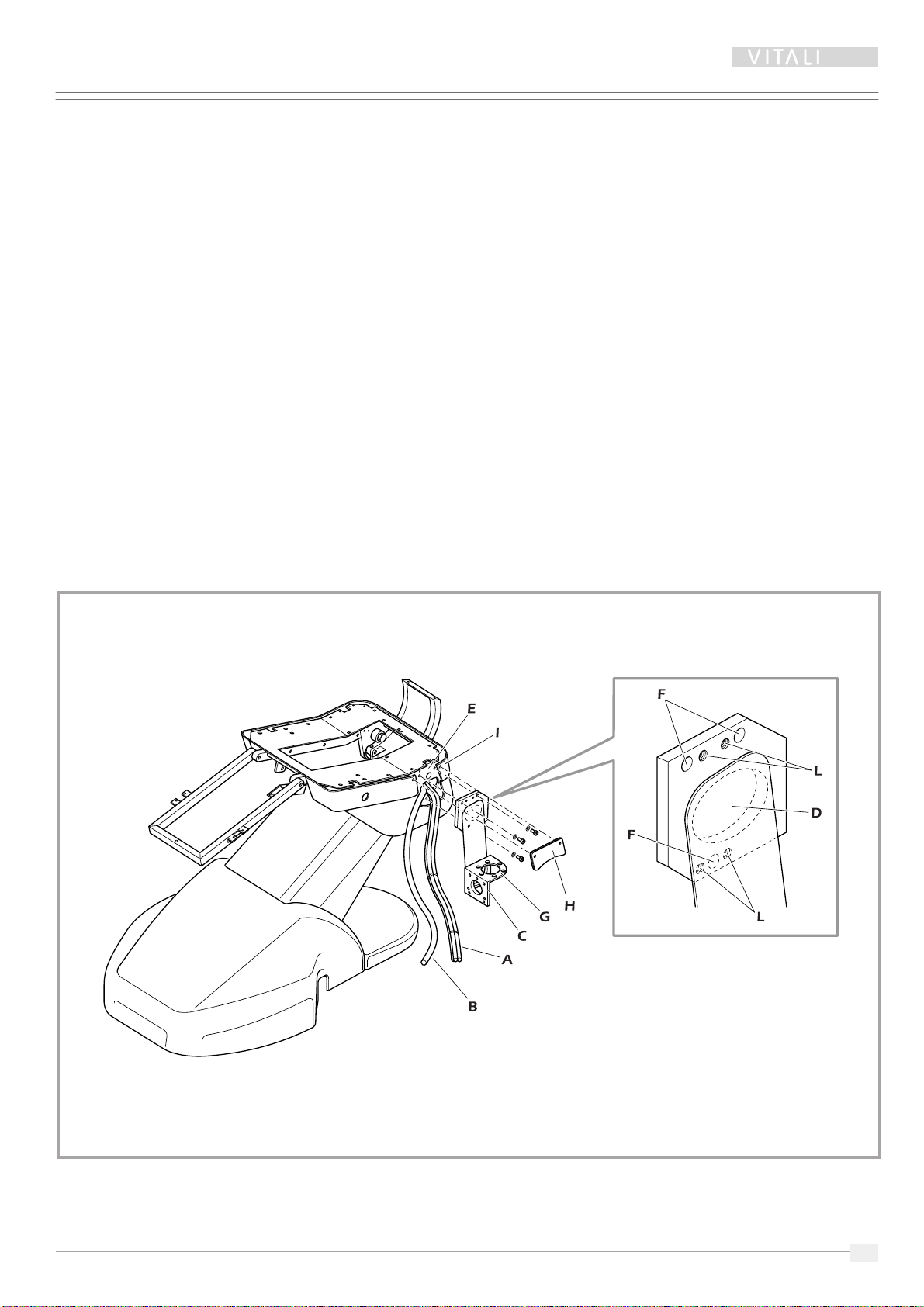

Mounting the dental unit bracket on the chair

Proceed as follows:

1) Insert the tube bundle “A” (bundle of electrical cables clamped to the ribbed grey suction hose id. 25 and the

sheath containing the air and water intake hoses) through the hole “D” in the bracket “C”.

2) Insert the hose "B" (transparent Armovin water drainage hose diam. 20x27).

3) Attach the bracket in area "E" through the holes "F" using the three M10 Allen screws.

4) Level using surface "G" as a reference by means of the four M10 dowels "L" and tighten the three M10 Allen

screws.

5) After fastening the bracket, cut the plastic clamps on the bundle of hoses "A".

6) Fit the closing guard "H" on the seat guard "I" and fasten by means of the countersunk screws M6 supplied.

7) Cover the M6 screws using the two white covers supplied.

T5

12

B

C

A

LEFT-HANDED DENTAL

UNIT BRACKET

WATER UNIT FRAME VIEWED

FROM BELOW

N°2 Allen screws

Type M8, mounted by us

LEFT-HANDED

VERSION

Assembling the water unit

Follow the instructions below to assemble the water unit:

1)

Use the 3 M8 Allen screws “A” to fasten the water unit, inserting them through the holes “B” in the bracket “C”.

RIGHT

VERSION

B

C

A

RIGHT-HANDED DENTAL

UNIT BRACKET

WATER UNIT FRAME VIEWED

FROM BELOW

N°2 Allen screws

Type M8, mounted by us

13

T5

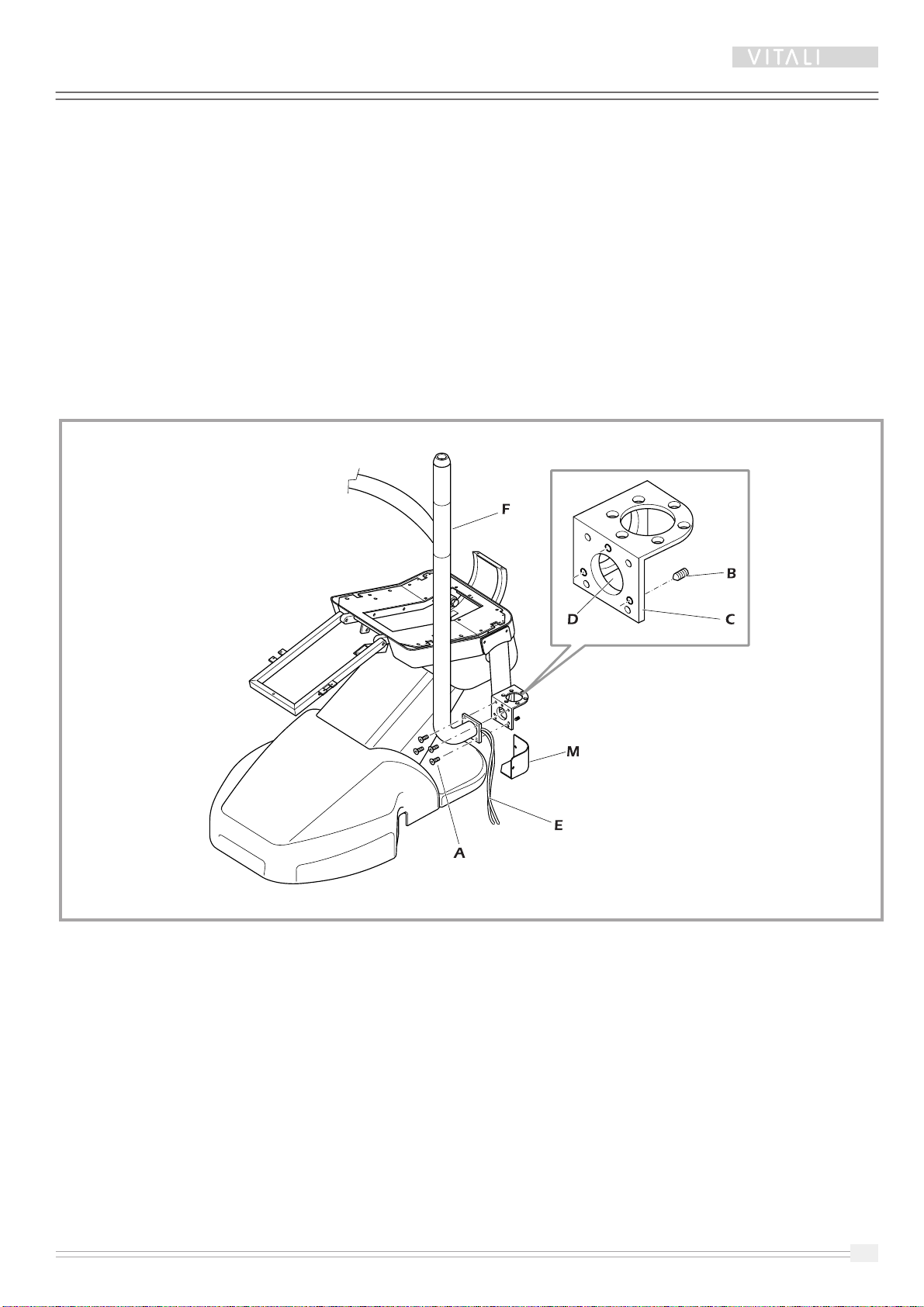

Assembling the instrument table arm

Proceed as follows to assemble the instrument table arm:

1) Insert all of the cables and hoses “E” from the instrument table arm through the hole “D”

2) Secure the tray table to the dental unit bracket with the four M8 screws “A” provided, level the arm with the three

M10 dowel pins “B” located on side "C".

3) Level using surface "F" as a reference allowing for possible bending and tighten the four Allen M8 screws "A".

4) Tighten the three M10 dowels "B" to avoid losing the leveling adjustment.

5) After installation, apply protection guard "M" on the bracket "C" by means of the two M5 screws.

T5

14

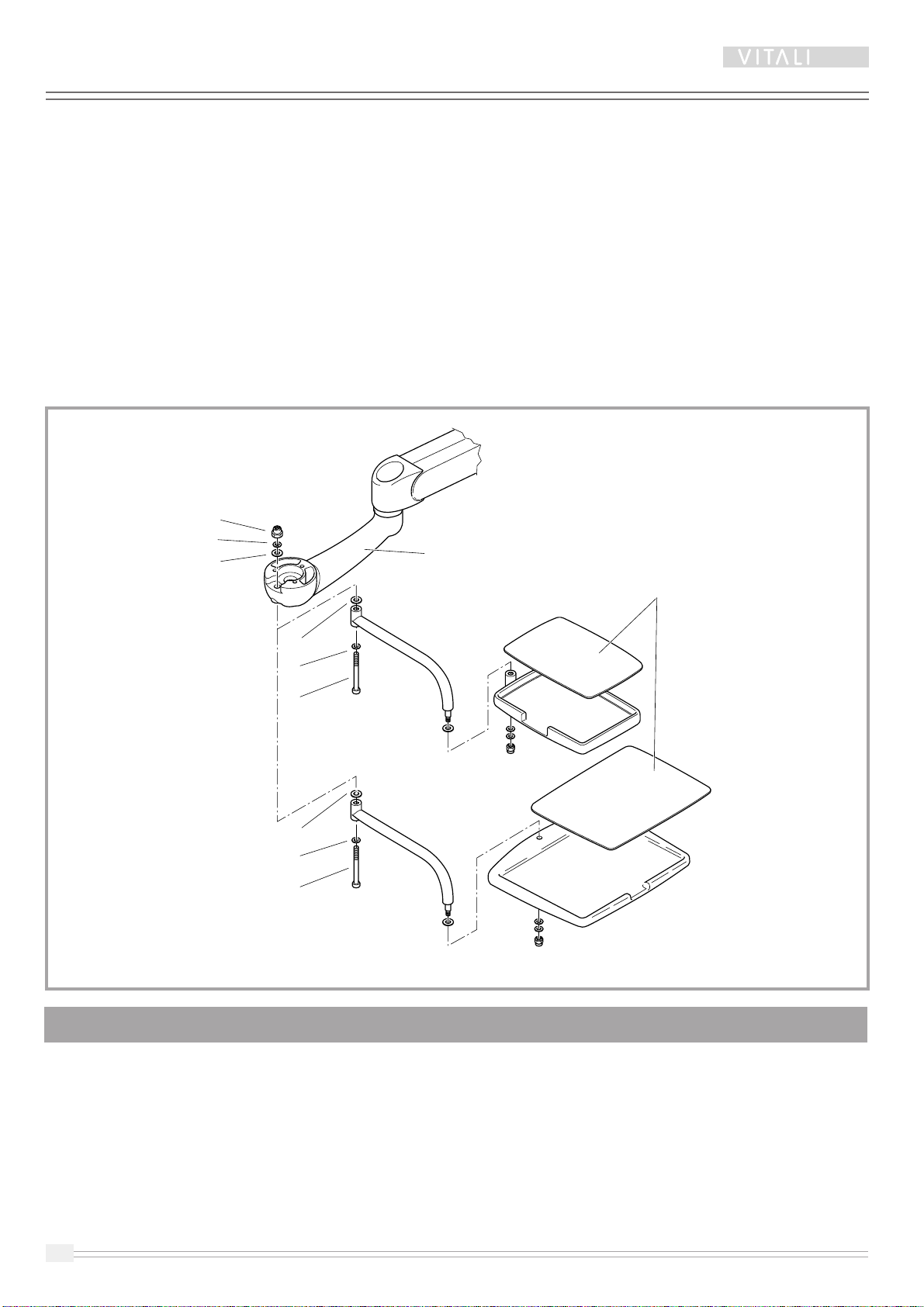

The tray table is supplied assembled. Fasten it to the instrument table support “A” as follows:

1) Use the M12 Allen screw “B” to fasten it to the instrument table support “A”, making sure to insert the nylon

washers "C", "D", "E" and the metal washer "F".

2) Finally, adjust the correct friction by means of the M12 nut "G".

Assembling the tray table

☞NOT

E: maximum weight applicable to the tray table = 1.5 kg.

A

G

F

E

D

C

B

D

C

B

Silicone protection,

washable in autoclave

15

T5

☞

NOTE:

The water unit, instrument table arm

and dental unit bracket are supplied

disassembledandappropriately packed. During

installation, failure to correctly complete all of

thegroundingconnections shown will seriously

compromise the safety and proper operation

of the equipment

CORRECT GROUNDING

CONNECTION

Grounding connection

water unit - dental unit bracket - instrument table arm

Water unit

electrical connection

1 2 3 4 5 6 7 8

ON

59400001

☞NOTE:Connect the connectors to the

card indicated, respecting the

numbering marked on the

connectors (see paragraph "Dental

Unit Electrical Group").

T5

16

Assembling the instrument table

To access the interior of the instrument table, see the chapter on "Accessing the internal parts of the instrument

table".

Before fastening the instrument table, insert all of the cables from the support “A” through the hole “C” at the bottom

of the instrument table.

Use the 3 M8-screws “B” provided to fasten the instrument table to the support “A”.

C

A

CLUTCH

MECHANICAL

STOP

NOTE: CHECK THE SERIAL NUMBER ON THE

BOTTOM OF THE INSTRUMENT TABLE, TO MAKE

SURE IT MATCHES THE ONE SHOWN ON THE

SERIAL NUMBER PLATE OF THE WATER UNIT.

B

This manual suits for next models

1

Table of contents

Other VITALI Medical Equipment manuals