Charging batteries

A tone when using the lift indicating that the batteries need recharging.

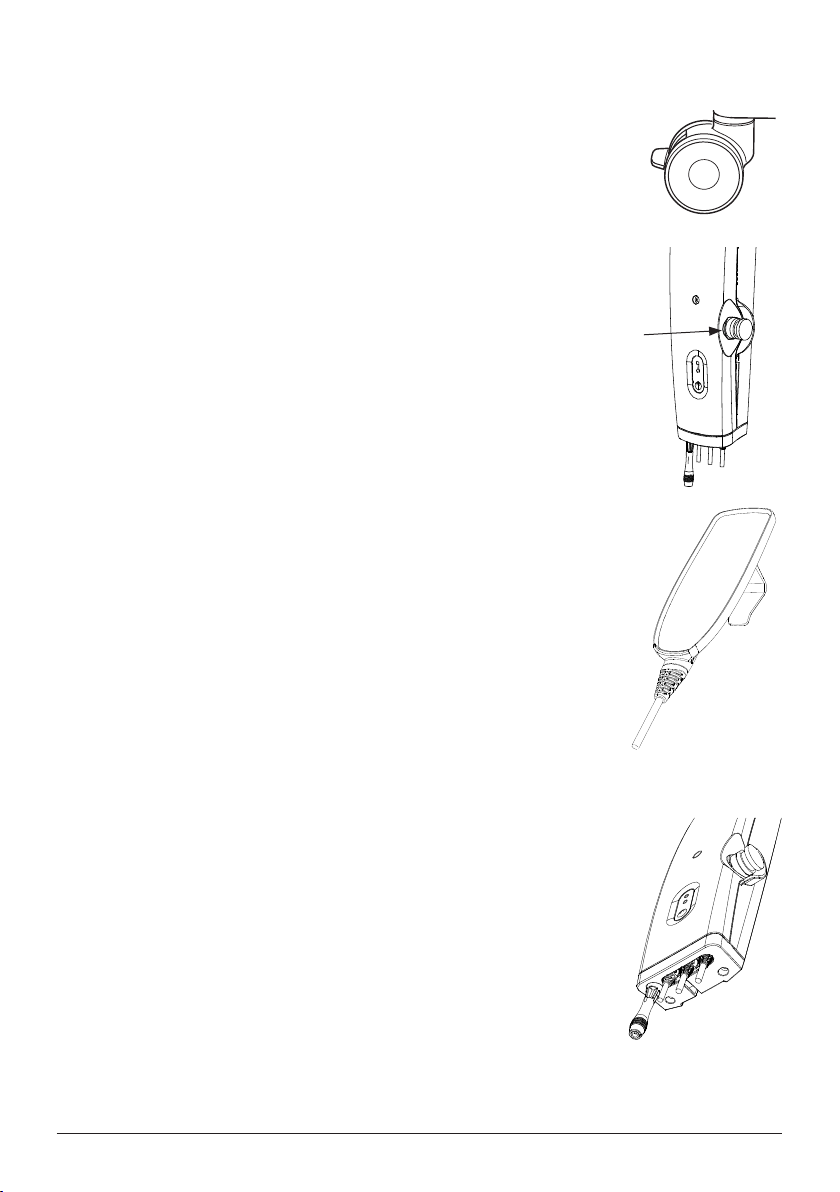

Lock the casts when charging the battery.

Make sure the emergency stop button is not pressed in.

Charging procedure:

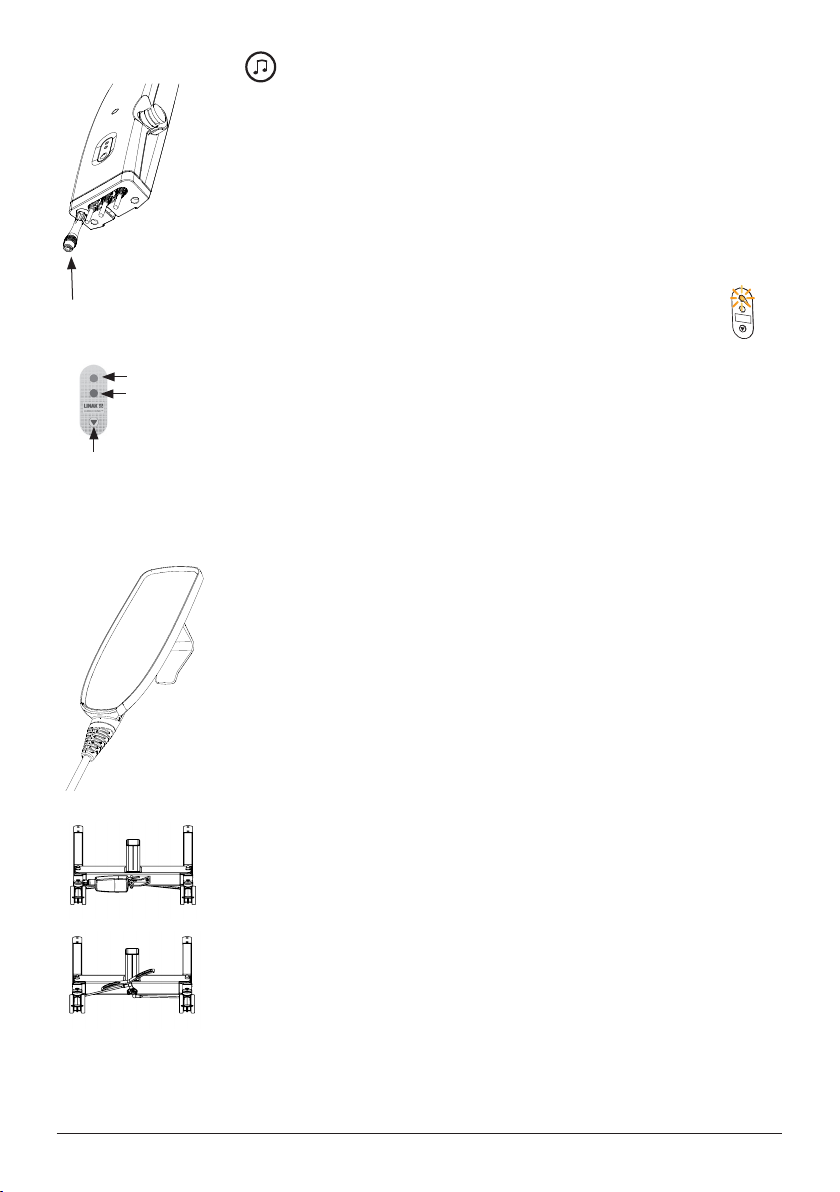

1. Connect the charger to the charger cable leading from the underside of the control

box.

2. Connect the charger to a power outlet (100-240 V AC).

3. When the charger is connected, the control box lamp indicates a yellow light.

NOTE!

Before the lift is used for the first time, it must be charged for at least 4 hours.

Charge batteries regularly for maximum longevity. We recommend daily charging when

the lift is in daily use.

The emergency stop button must be pulled out during charging.

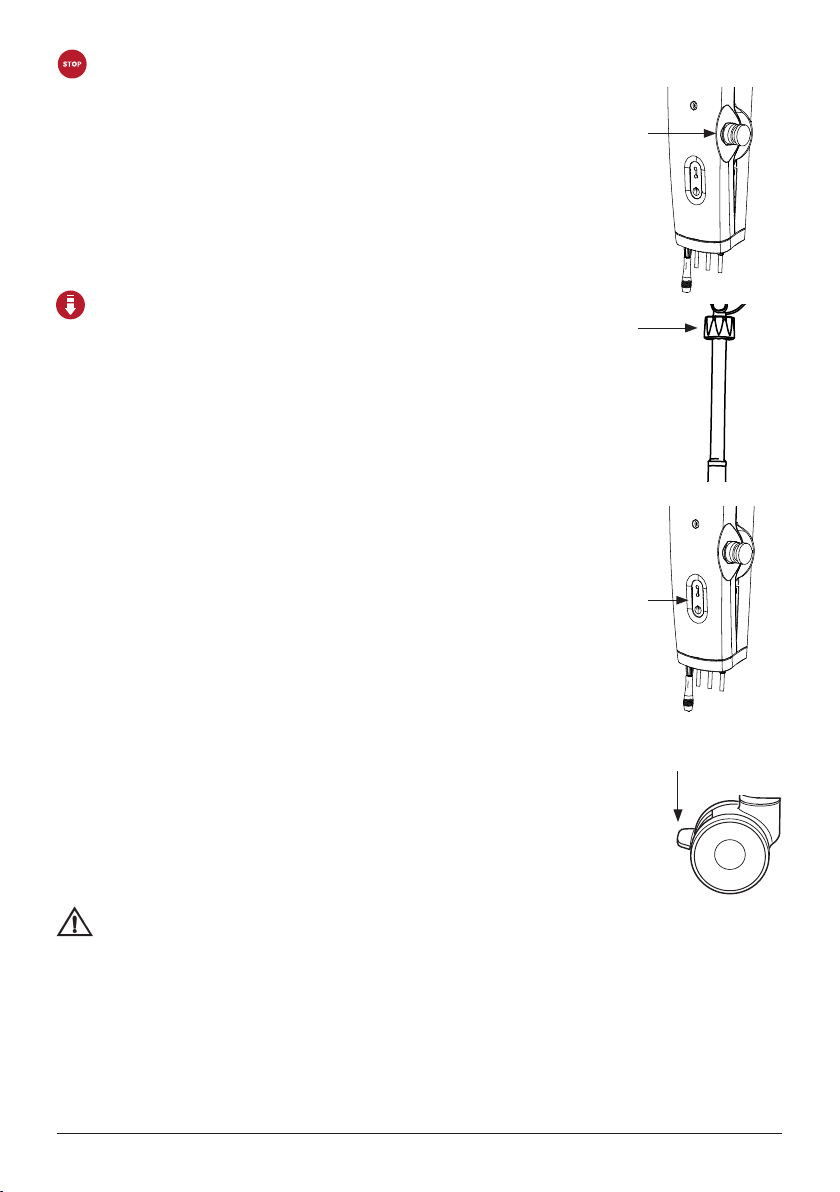

Handset

Raising/lowering the lift arm

Symbol indicate direction of travel.

Motion stops as soon as the button is released.

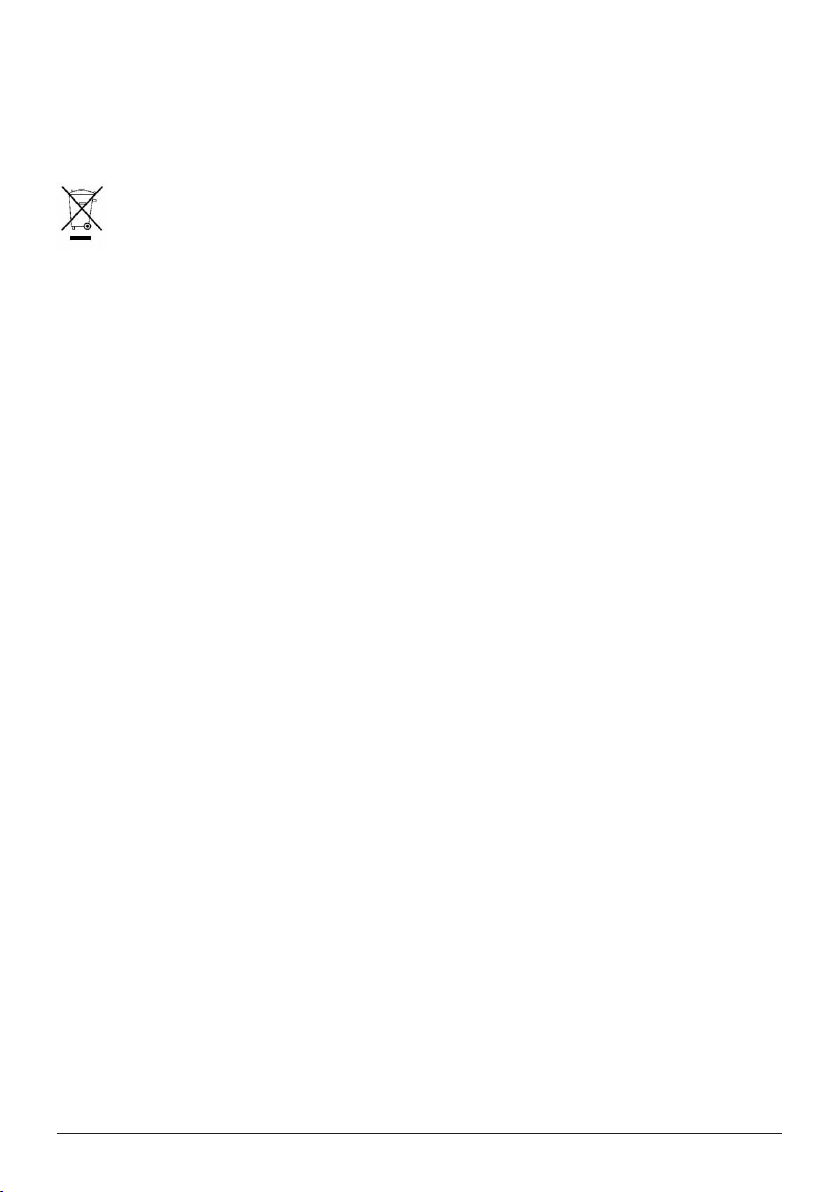

Base-width adjustment

Manual base-width adjustment (model EM)

Push down on the respective pedals at the back of

the lift to widen and narrow the base.

LED

indication of

charging

LED

indication

of handset

activation

Button for

electrical

emergency

lowering

Charger

6

Eva450EEL Eva600EEL

Eva450EML

REVISION HISTORY

REV.

DESCRIPTION

DATE

APPROVED

D

E

F

C

1

2

3

4

B

A

3

2

1

5

C

D

4

6

7

8

A

B

SCALE:1:10

DWG. NO.

REV.

NAME

DATE

DRAWN

APPROVED BY

SHEET 1 OF 1

WEIGHT:

COMMENTS:

STATUS:

TITLE

MATERIAL:

SIZE

Released

EVA EEL 450 base

90001288 02

g

2011-05-20

A3

Unless otherwise stated, general

tolerances according to ISO 2768-m

hc-jope

This drawing and any information or descriptive matter set out hereon are the confidential and copyright property of Handicare

and must not be disclosed, loaned, copied or used for manufacturing, tendering or any other purpose without their written permission.

Eva450EEL Eva600EEL

Eva450EML

REVISION HISTORY

REV.

DESCRIPTION

DATE

APPROVED

D

E

F

C

1

2

3

4

B

A

3

2

1

5

C

D

4

6

7

8

A

B

SCALE:1:10

DWG. NO.

REV.

NAME

DATE

DRAWN

APPROVED BY

SHEET 1 OF 1

WEIGHT:

COMMENTS:

STATUS:

TITLE

MATERIAL:

SIZE

Released

EVA EEL 450 base

90001288 02

g

2011-05-20

A3

Unless otherwise stated, general

tolerances according to ISO 2768-m

hc-jope

This drawing and any information or descriptive matter set out hereon are the confidential and copyright property of Handicare

and must not be disclosed, loaned, copied or used for manufacturing, tendering or any other purpose without their written permission.