PEERLESS SmartMount SP740P Guide

Other PEERLESS Rack & Stand manuals

PEERLESS

PEERLESS PANA-85WM Guide

PEERLESS

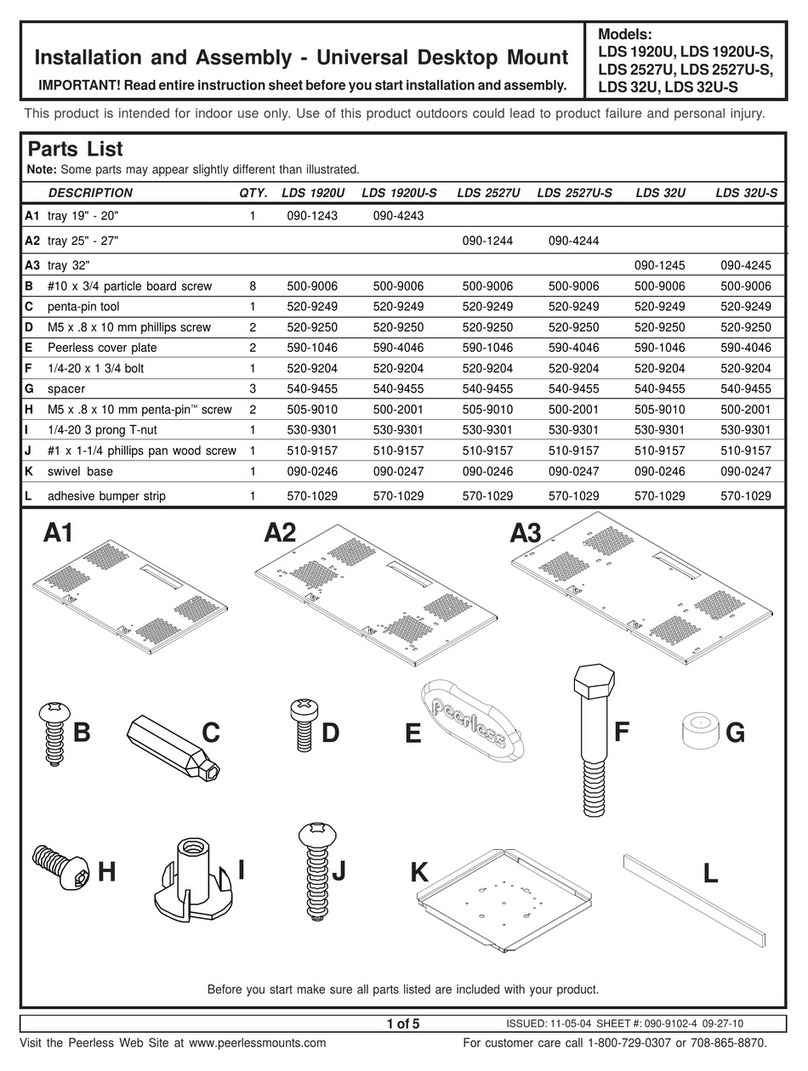

PEERLESS LDS 1920U Guide

PEERLESS

PEERLESS SmartMount RTFPA45 Guide

PEERLESS

PEERLESS HCW201 User manual

PEERLESS

PEERLESS JMWS 30 Guide

PEERLESS

PEERLESS SUF650P and assembly Guide

PEERLESS

PEERLESS HCW101 User manual

PEERLESS

PEERLESS SGLS01 User manual

PEERLESS

PEERLESS ACC 314 Guide

PEERLESS

PEERLESS SAL730P Guide

PEERLESS

PEERLESS WSP 716 User manual

PEERLESS

PEERLESS LMAM1940 Guide

PEERLESS

PEERLESS DS-VL-H018 Guide

PEERLESS

PEERLESS SA761P Guide

PEERLESS

PEERLESS ACC517 Guide

PEERLESS

PEERLESS Vision-Point LCV 100 Guide

PEERLESS

PEERLESS Paramount PT650 Guide

PEERLESS

PEERLESS IMC 18 Guide

PEERLESS

PEERLESS ST 640 Guide

PEERLESS

PEERLESS IM760P Guide

Popular Rack & Stand manuals by other brands

Salamander

Salamander Acadia AC/W/L400/WH Assembly instructions

Fohhn

Fohhn VAT-09 Mounting instruction

ricoo

ricoo FS0522 quick start guide

AMSOIL

AMSOIL BMK-22 Installation and service instructions

Kargo Master

Kargo Master 48220 installation guide

Milestone AV Technologies

Milestone AV Technologies SIMPLICITY SLF2 installation instructions