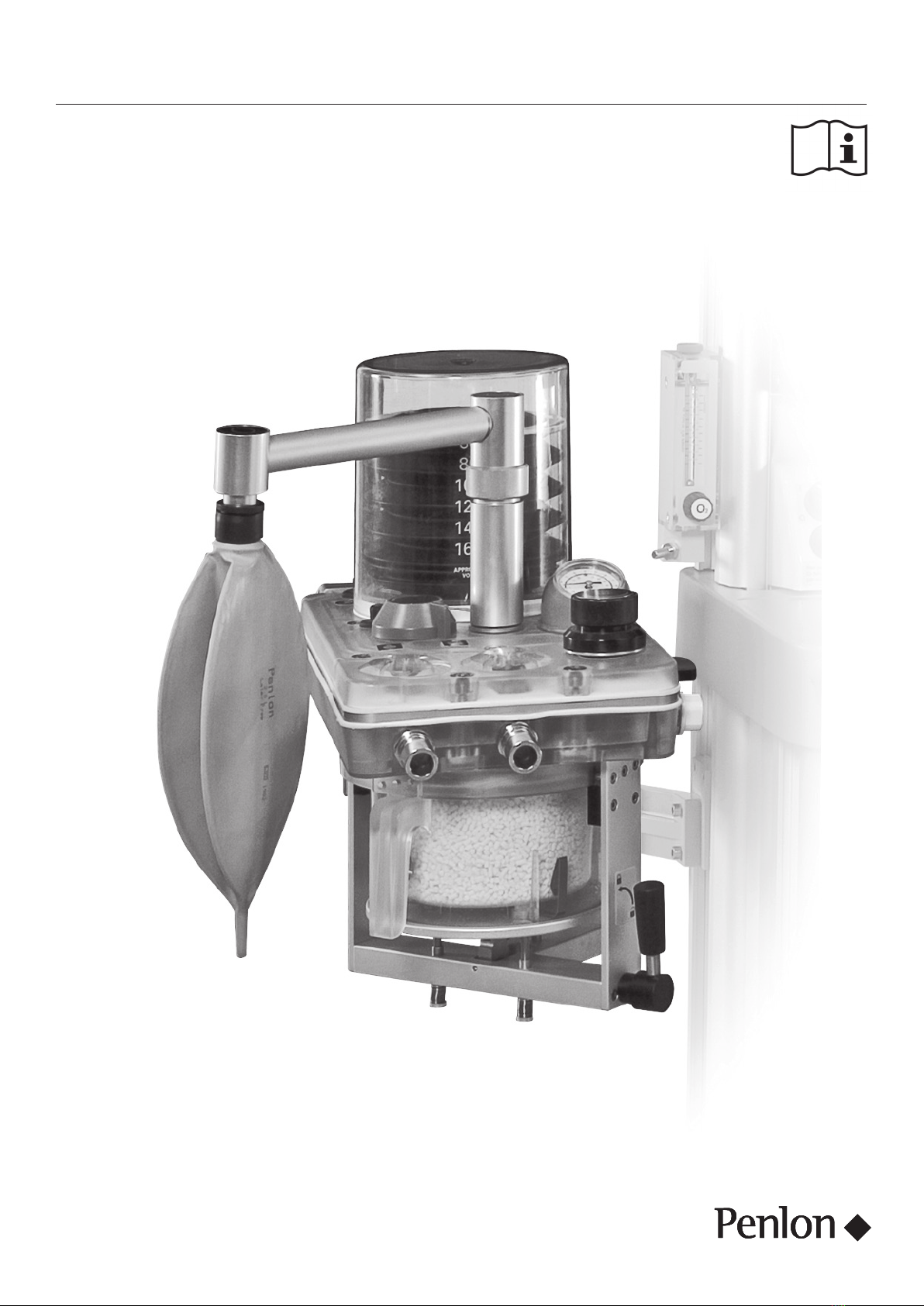

A200SP Absorber 2 User Manual

1. Warnings and Cautions

The followng WARNINS and AUTIONS must be read and

understood before usng ths Anaesthetc Apparatus

WARNINS

1 Personnel must make themselves famlar wth the

contents of ths manual and the functon of the A200SP

Absorber before use

2 Trchloroethylene must not be used n assocaton wth

soda lme

3 Ths unt s restrcted to use wth non-flammable

anaesthetc agents only

4 The A200SP Absorber must only be used when securely

mounted n an uprght poston

a) The nspratory and expratory non-return valves

(NRV) are gravty operated See secton 32

b) Spllage of absorbent may contamnate the breathng

system See secton 51

5 To avod the rsk of electrc shock, ths equpment must

only be connected to a mans supply wth a protectve

earth

6 To solate the machne from the mans power supply,

dsconnect the mans cable from the mans power outlet

Always use an easly accessble mans power outlet

7 Ths devce must not be altered or modfed n any way

wthout the wrtten approval of Penlon Lmted

Before usng the absorber

8 Breathng system connecton Do not use a patent

Y-pece contanng non-return valves Usage wth the

Absorber s hazardous, because two sets of non-return

valves may easly be connected n opposton, by error

See secton 52

9 Breathng hoses and bags used wth the absorber must

comply to BS EN ISO 5367 (Hoses) and BS EN ISO 5362

(Breathng Bags) respectvely

10 Do not connect a vacuum systems must not drectly to

the adustable pressure lmtng (APL) valve outlet A

recevng system wth postve and negatve pressure

control functons must be nterposed Systems must

comply wth EN ISO 8835 Part 2 or BS EN ISO 80601-2-

13 See secton 523

11 The APL valve s out of crcut when the system s n

‘Ventlator’ mode The ventlator must be equpped wth a

pressure relef valve

12 Underfllng of the canster can lead to neffcent O

absorpton Overfllng may result n poor sealng of

canster due to cakng of granules and abrason of the

canster and seal See secton 532

13 Anhydrous soda lme s known to react wth some

anaesthetc agents Do not contnue to use an absorbent

f t has been allowed to dry out (or f you suspect t has

dred out) Always replace dred-out absorbent wth a

fresh supply of soda lme

14 Do not use the absorber wthout ensurng that t passes

all pre-use checks See secton 6After servcng and

cleanng procedures, verfy postve acton of the bag/

ventlator selector swtch before the unt s used

clncally

heck that at all tmes that the swtch s free to move

from one end of ts travel to the other

Usng the absorber

15 ondensaton, whch may collect n the bottom of the

absorber canster s caustc and care must be taken not

to spll t on the skn when dranng See secton 73

16 Knkng of the fresh gas hose s a known cause of

anaesthetc accdent The use of an unsutable hose

assembly can contrbute to ths stuaton

See secton 35

17 Any system utlsng the A200SP absorber must be ftted

wth

a) An oxygen montor complyng wth ISO/IE 80601-2-

55

b) A carbon doxde montor complyng wth ISO/IE

80601-2-55

c) A mnute volume montor

d) A breathng system ntegrty alarm

18 Refttng the canster

The canster seals at the top face Mantan the poston

of the rm of the canster over the outer lp of the seal as

you rotate the lever ant-clockwse to the vertcal, locked-

on poston

Falure to lock the canster n the fully closed poston,

may cause a system leak and/or a reducton n O

absorpton

19 Heater unt (f ftted)

Exteror panels must not be removed by unauthorsed

personnel, and the unt must not be operated wth such

panels mssng

There s a possble electrc shock hazard

20 Portable RF communcatons equpment (ncludng

perpherals such as antenna cables and external

antennas) should be used no closer than 30 cm (12

nches) to any part of ths devce, ncludng cables

specfed by the manufacturer Otherwse, degradaton of

the performance of ths equpment could result

21 You must only use non-conductve breathng system

hoses Breathng hoses must not have electrcally

conductve propertes

22 Ths machne s not sutable for use n oxygen-rch

envronment

23 Do not touch any electrcal devce connector at the same

tme as the patent