3

1Introduction

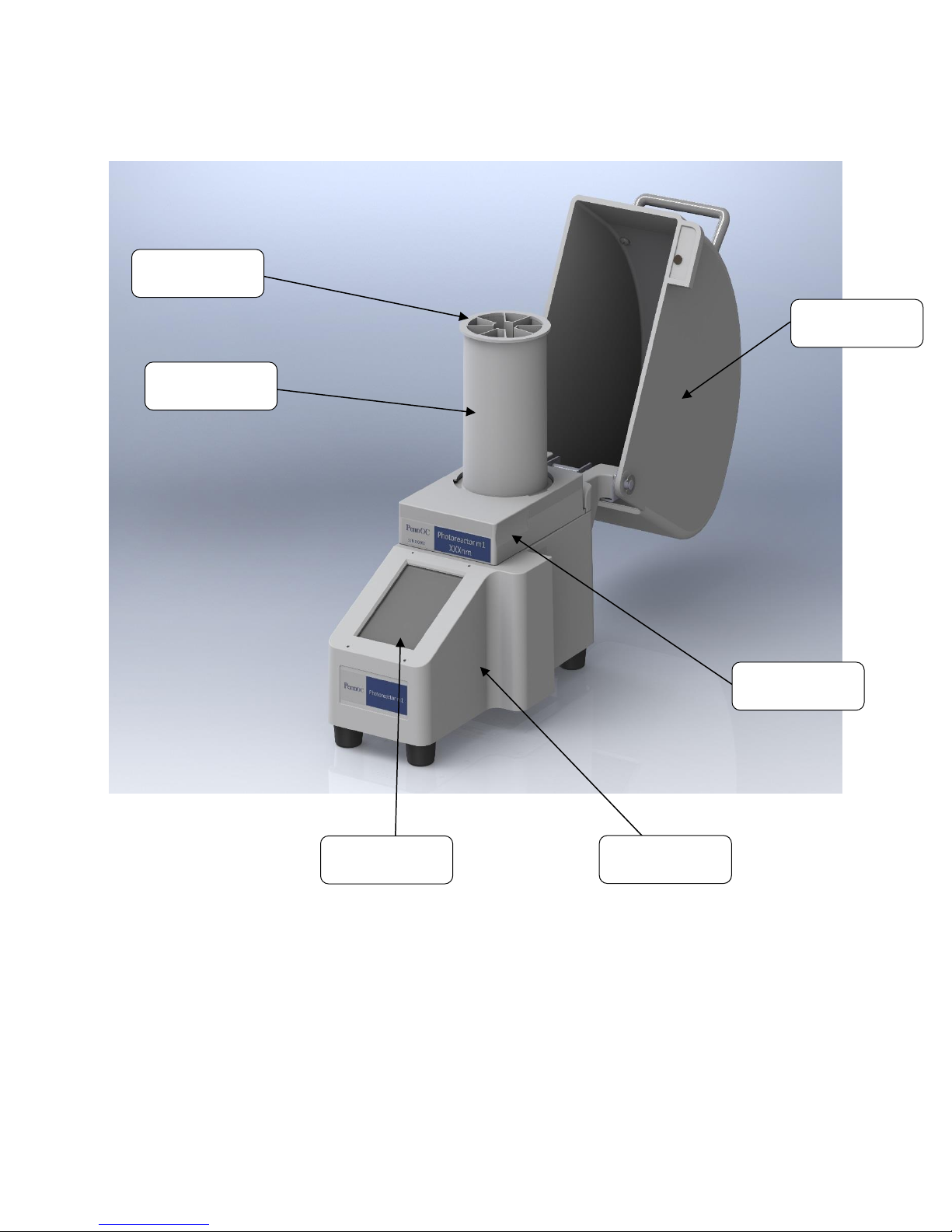

The Photoreactor m2 is a benchtop instrument designed for chemists and researchers to accelerate

chemical reactions using photoredox catalysis. The Photoreactor m2 combines LED illumination,

mechanical stirring and cooling in one device. The user defined parameters of temperature, intensity,

stir rate and time, creates a valuable tool for repeatability, traceability, efficiency and consistency of

results. The Photoreactor m2 addresses the potential to streamline synthetic sequences, and create

valuable strategies for addressing some of the challenges of molecule construction in drug discovery.

Key Features:

•Photoreactor m2 is a complete benchtop instrument to accelerate photoredox catalysis

•Modular design allows for use with a variety of wavelengths from 365nm to 450nm

•360 degree reflective environment maximizes surface area photon capture

•Light shield interlock prevents user exposure to harmful light rays

•Interactive touch screen controls reaction parameters

•Intertek ETL, CE, and CB approved

•User defined parameters including temperature, light intensity, fan speed and stirring

•Auto stop, pause and reset options

•Supports vial sizes gc, 4, 8, 20, 40 ml

•Temp feedback using a k-type thermocouple

2Safety

Prior to use, the operator should thoroughly read the instructions for use. Using this device without

reading and understanding the instructions for use may result in operator injury or damage to the

equipment.

The device contains a powerful LED that produces extremely bright light. Do not look into the back end

of the device when the LED is activated as this may result in eye damage.

Only use the device with approved accessories. Proper care must be taken during setup and operation

to prevent injury to operators and other personnel or damage to the unit.

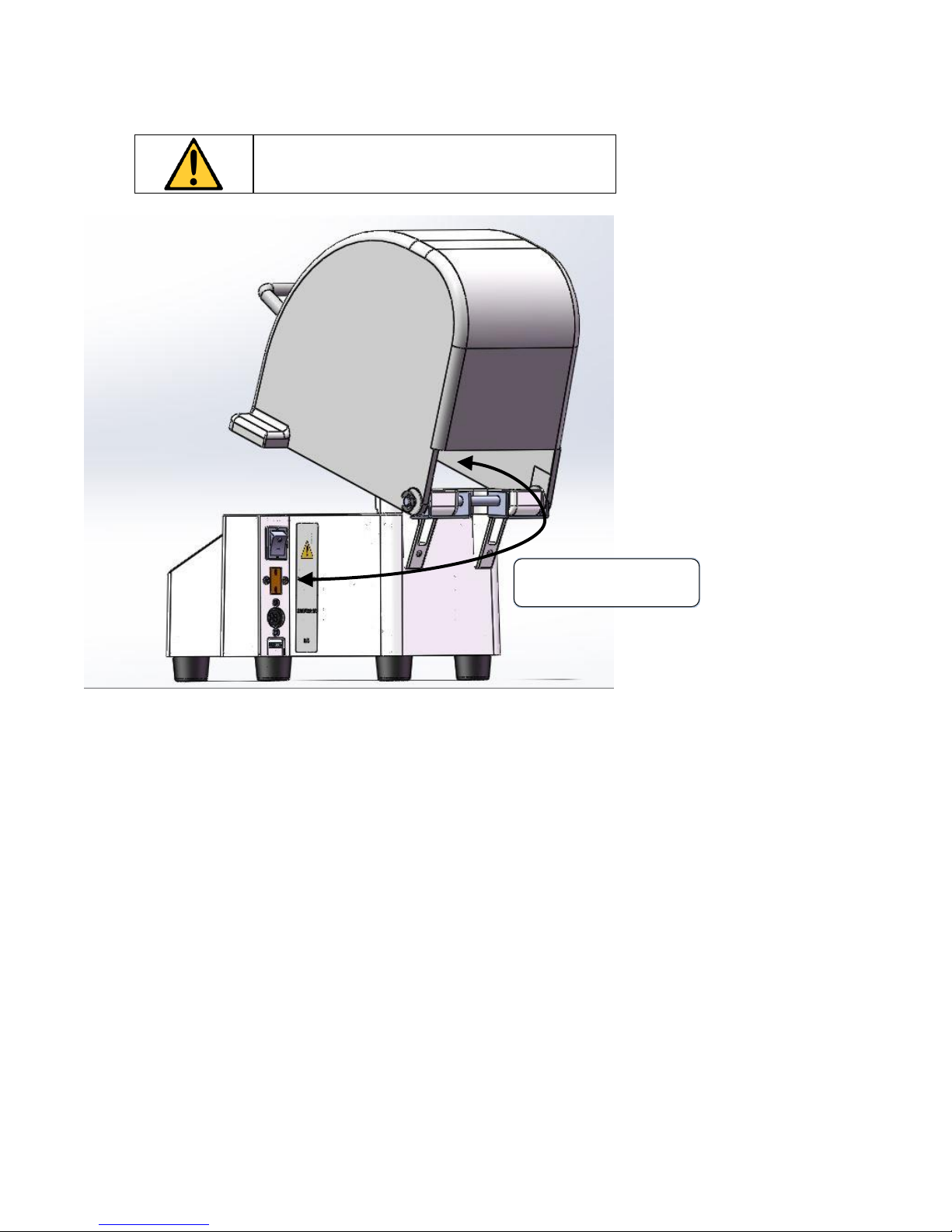

The unit is equipped with multiple safety features including an interlock device that will not permit LED

emission when the light shield is not in place. Keep magnets away from the device to prevent

accidental interlock activation.