1401 North Plano Road, Richardson, Texas 75081

Phone: 972-234-3202 | Fax: 972-497-0441 PENNBARRY 2

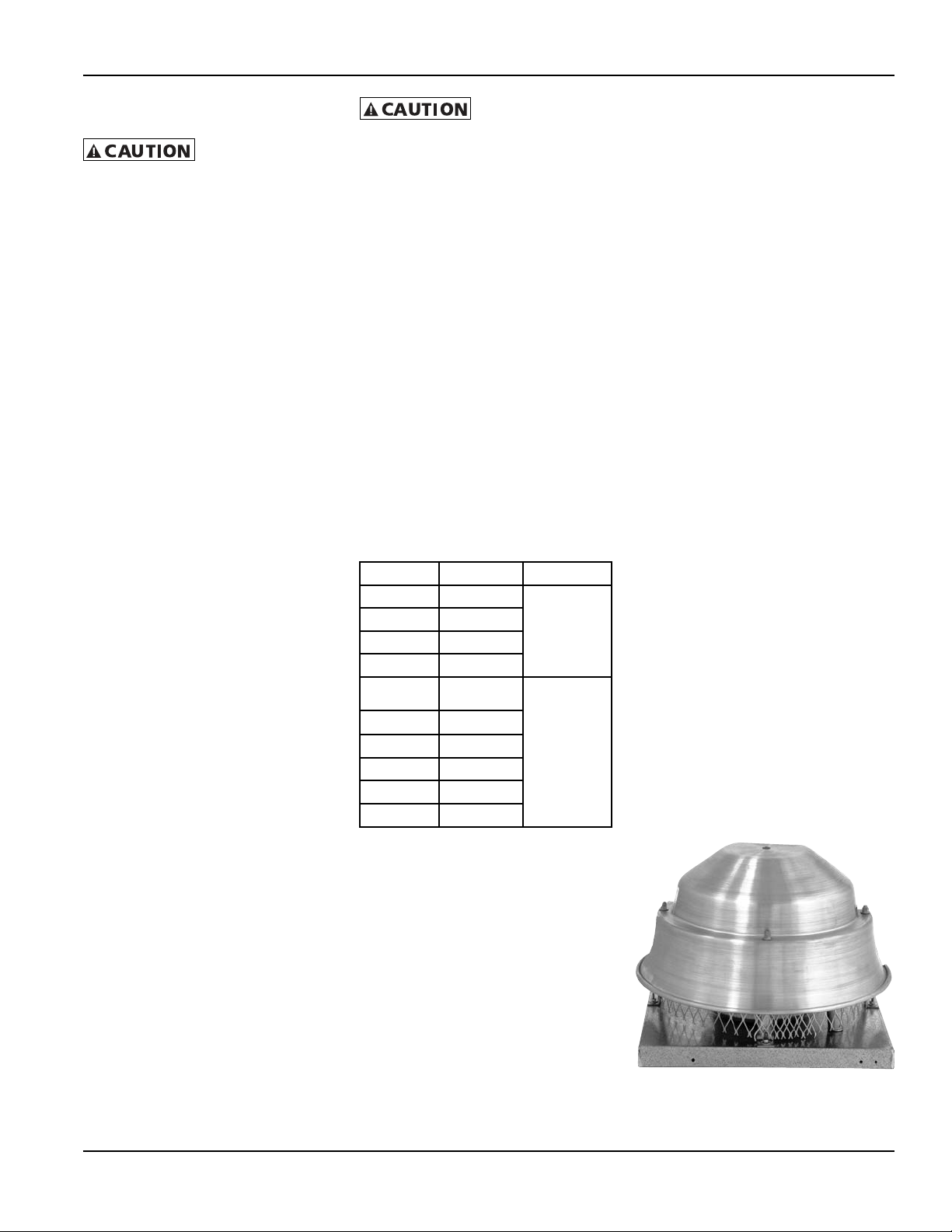

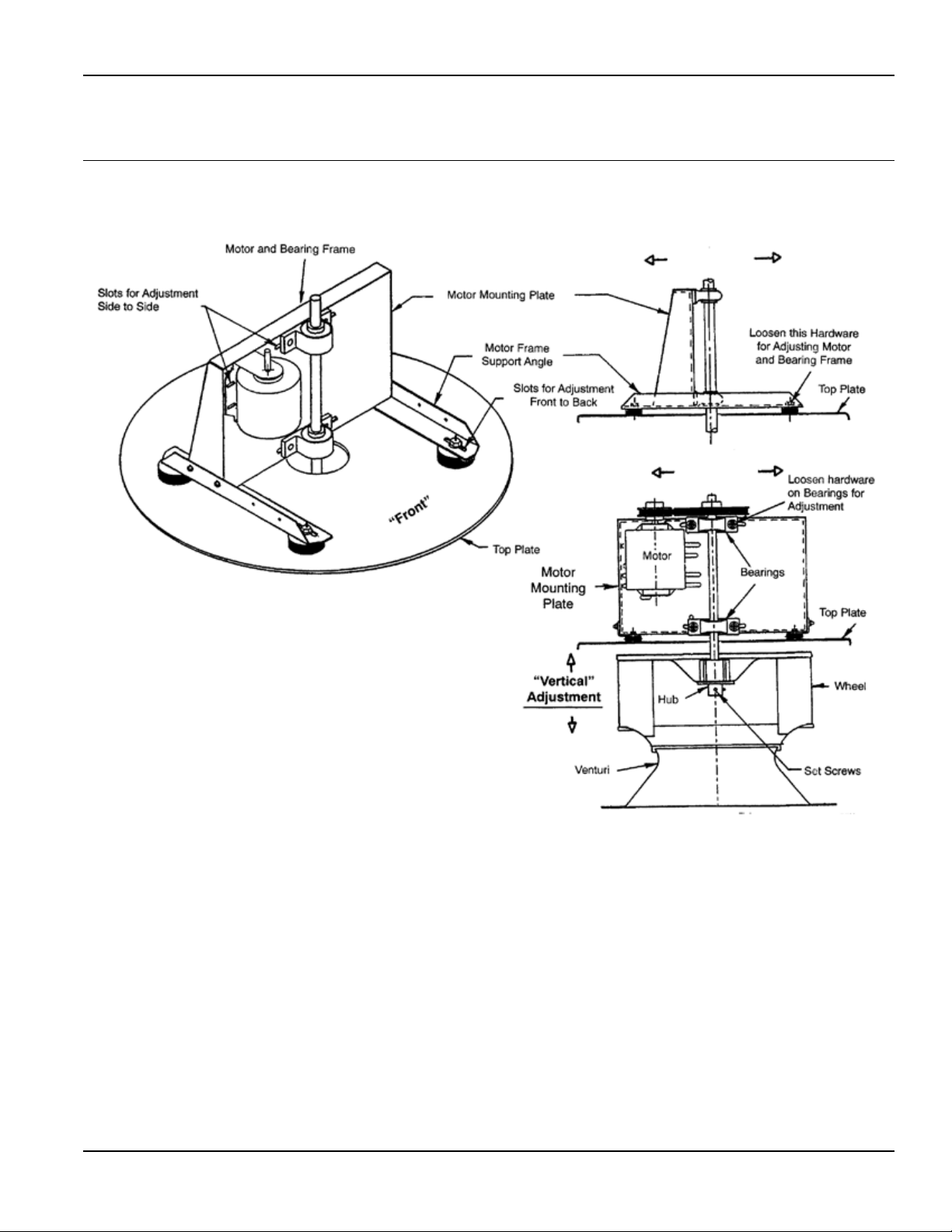

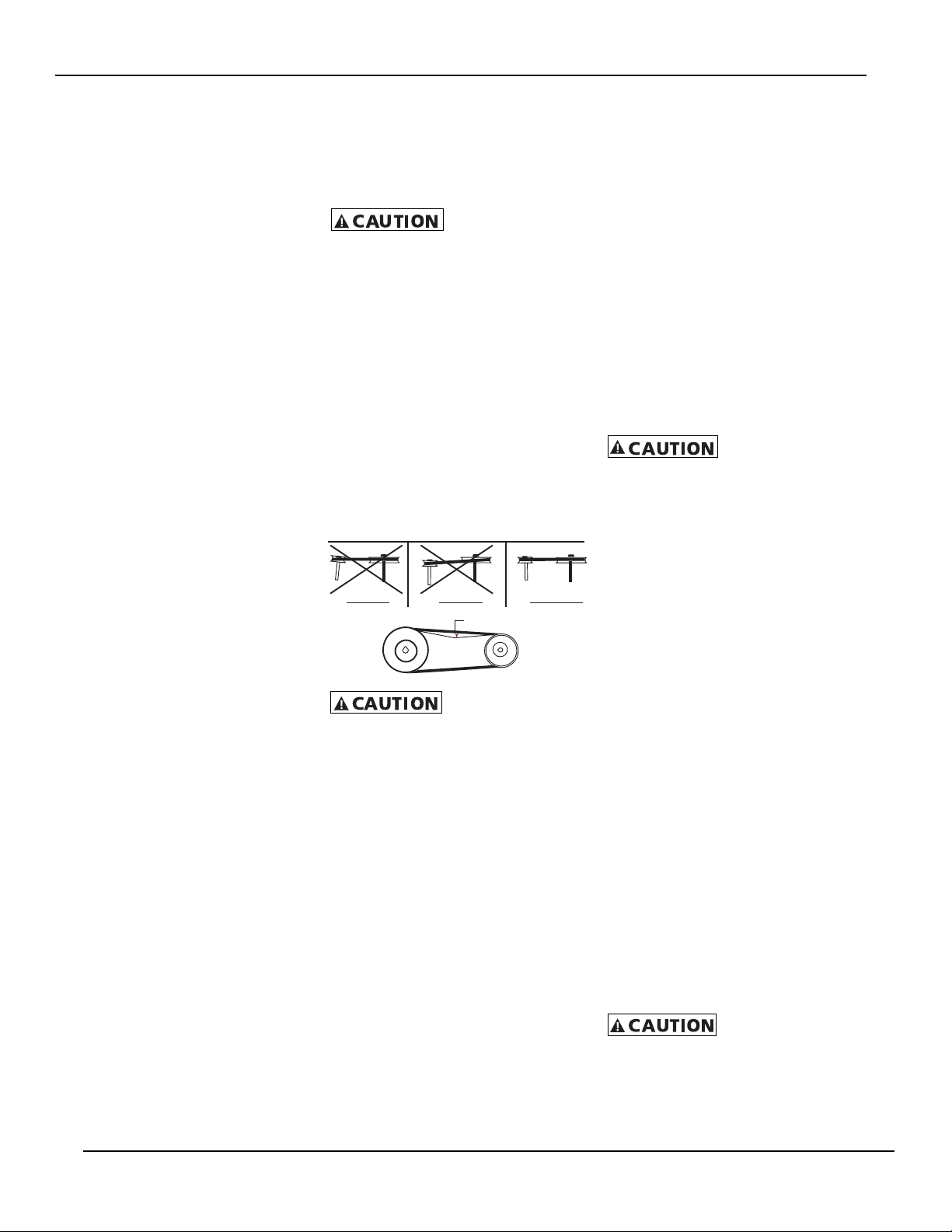

Not to exceed 1/64” per inch of span

WRONG WRONG CORRECT

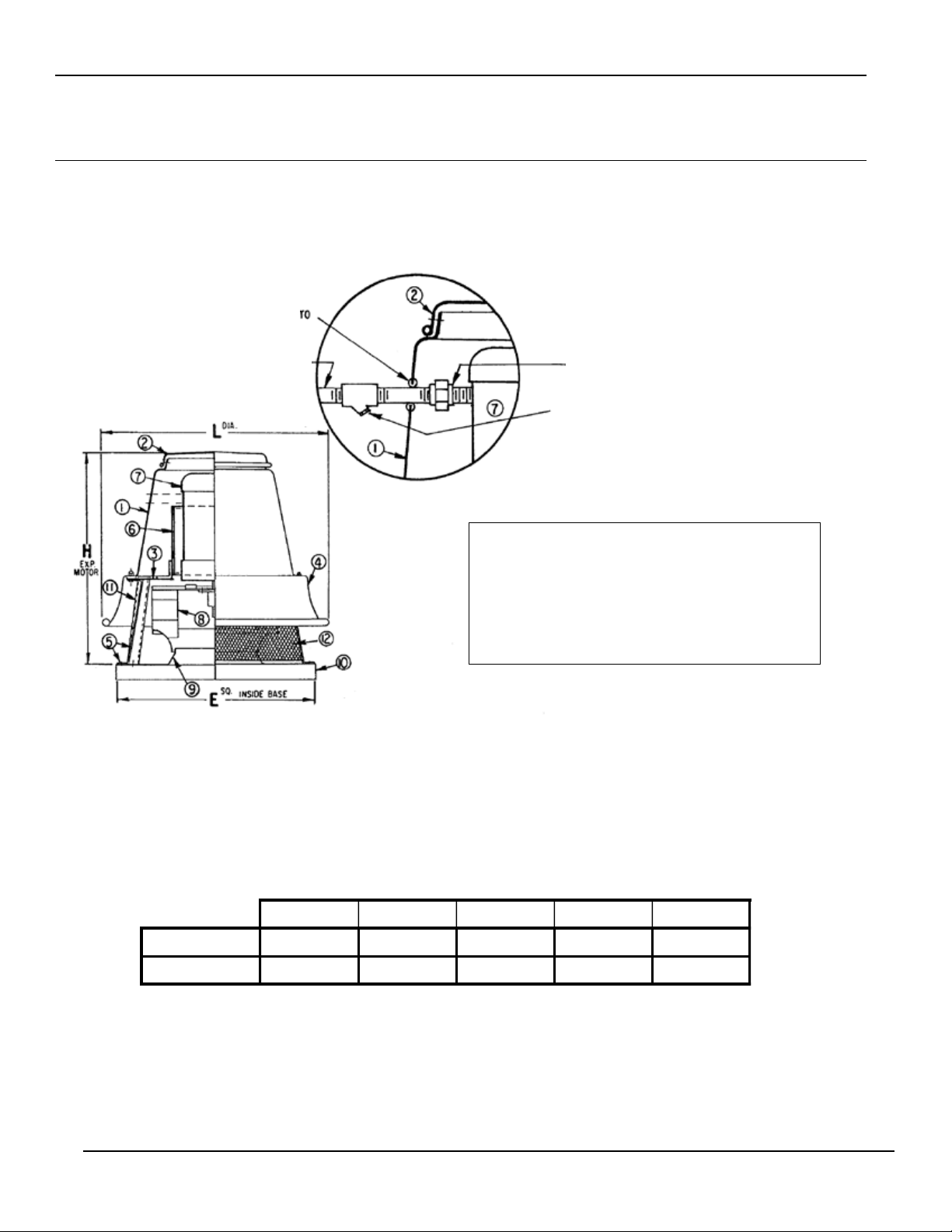

Operation & Maintenance Manual Domex, Centrifugal Roof, Direct & Belt Drive Exhausters

When power lines are brought up to the

unit, provide a generous amount of slack

to allow for motor adjustments and to per-

mit movement of motor for belt tension ad-

justments. Ground motor adequately and

securely. Protect power lines from sharp

objects. Do not kink power line or permit it

to contact hot surfaces, chemi-cals, grease

or oil. Use only UL recog-nized electrical

parts, rated for proper voltage, load and

environment. Check motor name plate.

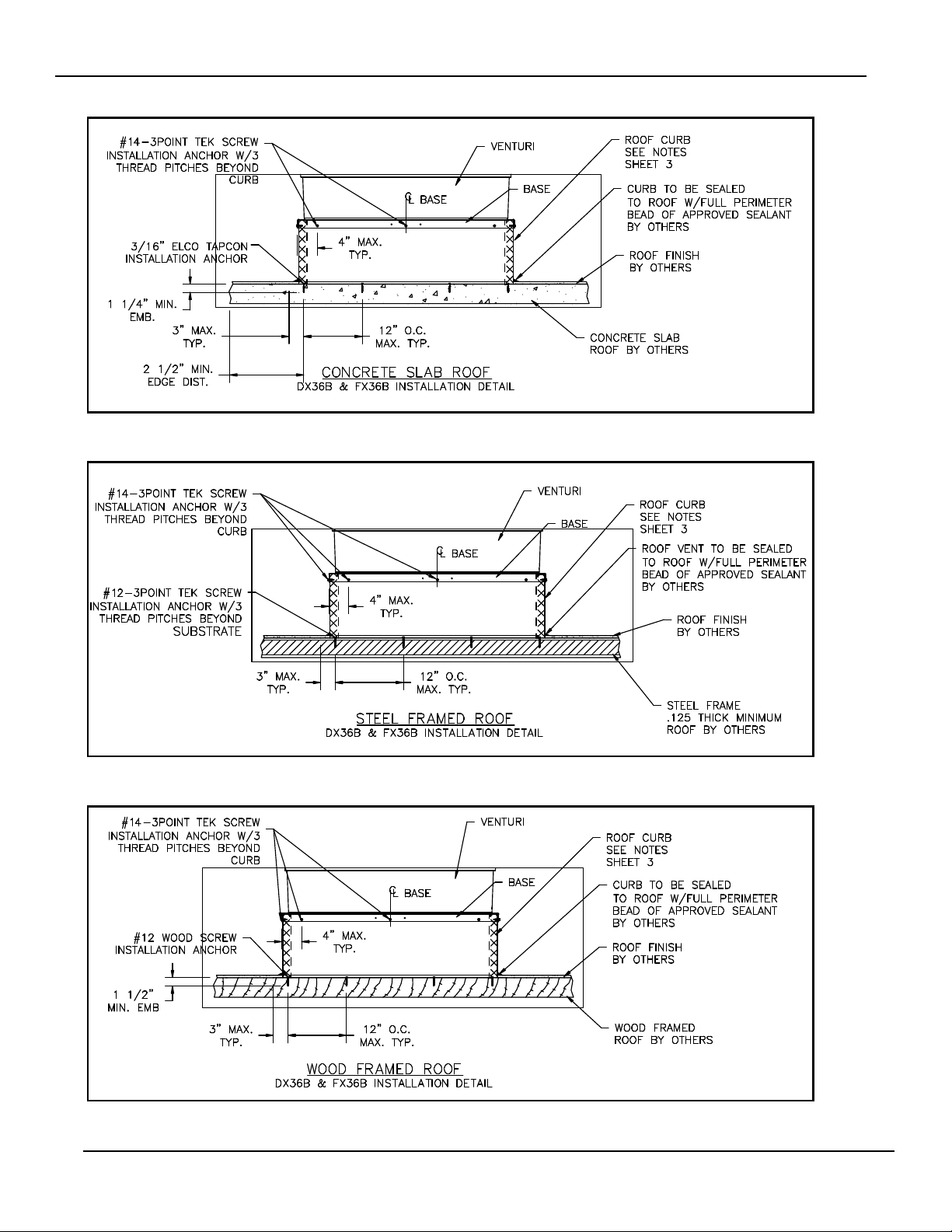

ANCHORING AND SECURING THE

VENTILATOR: ROOF MOUNTING

Whenever possible, anchor the fan by fas-

tening through the vertical portion of the

mounting ange. The type, size and num-

ber of fasteners depends upon the unit size

and curb construction. If code or specica-

tion prescribes fastening through the top

(vertical portion) of the mounting ange,

use neoprene or lead washers under the

head of each fastener.

Guy down large units installed in areas

subject to high winds or unusual eld con-

ditions. If the installer removes any venti-

lator parts to facilitate installation or elec-

trical connections, reassemble all parts by

replacing all spacers, washers, nuts, bolts,

fasteners and components exactly as they

were found prior to removal. Draw all fas-

teners tight and secure. Fasteners should

be protected against corrosion.

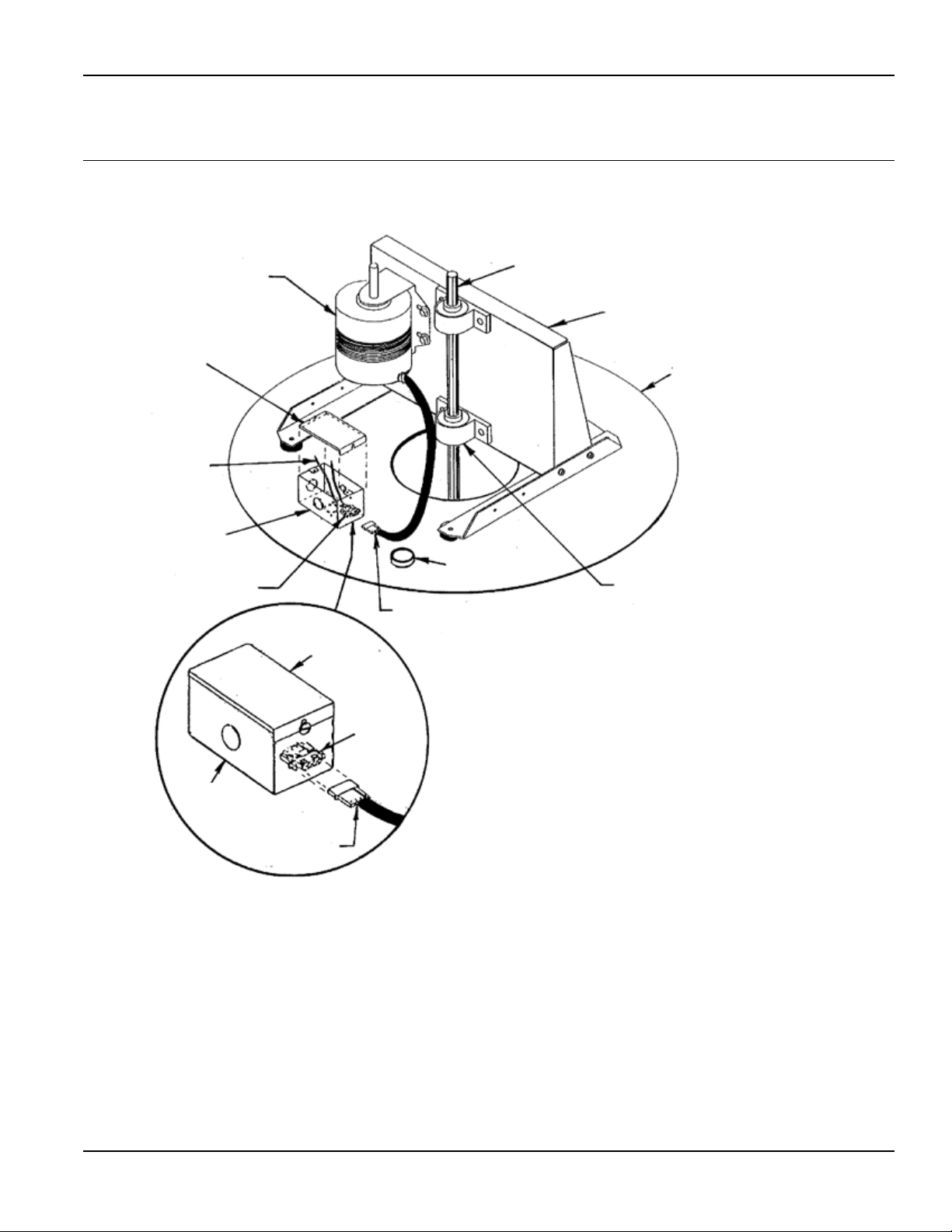

MOTOR INSTALLATION PROCEDURES

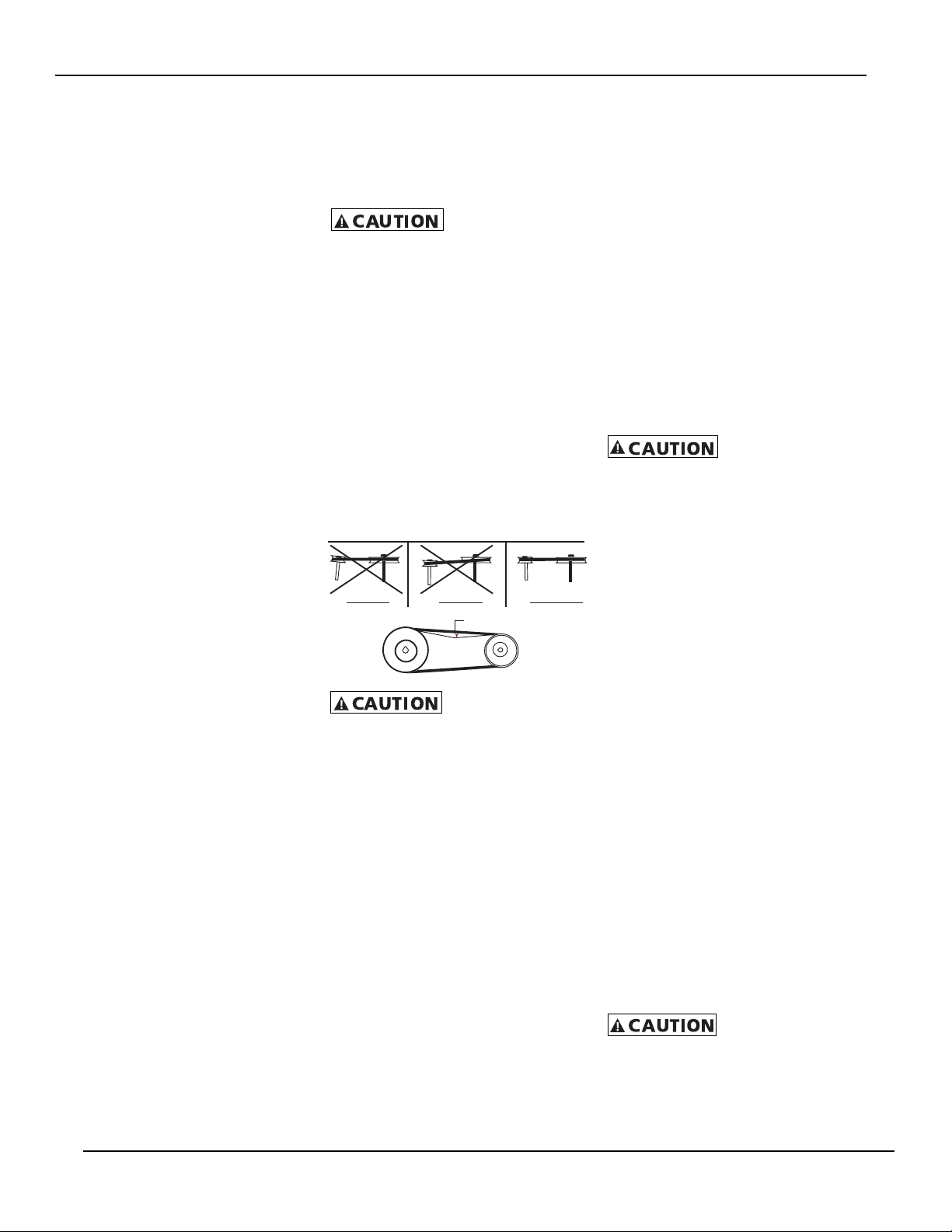

1. Install motor pulley assembly (bracket if

provided - type 3) with hardware pro-

vided through holes in motor mount-

ing plate/frame. Keep driven pulley

and drive pulley in line. (Do not tighten

hardware).

2. Install belt over drive and driven pul-

leys, pull up on motor mounting plate/

bracket until belt is tight. Tighten motor

plate hardware.

3. Wire motor or plug harness connec-tor

(from motor if equipped) into terminal

socket at end of junction box. Unit is

now ready to test to check for smooth

operation.

4. See belt adjustment label, and Fig.

4, for more details.

5. Check for proper wheel rotation.

Start-Up and Operation

Carefully inspect the unit before start-up.

All motor bearings should be properly lu-

bricated and all fasteners should be se-

curely tightened. Rotate centrifugal wheel

by hand to insure free movement.

Before placing hand

on centrifugal wheel

or belts, lock out power source.) Check all

set-screws and keys. Tighten when neces-

sary.

Check condition of belts and the amount

of tension prior to start-up. DO NOT over-

tighten, as bearing damage will occur.

Recommended belt tension should per-

mit deection of 1/64” per inch of span.

Exercise extreme care when adjusting

belts as not to misalign the pulleys. Any

misalignment will cause a sharp reduction

in belt life and produce squeaky, annoying

noises. On units equipped with two groove

pulleys, adjust all belts with equal tension.

Belts must be adjusted after approximate-

ly 40 hours of operation.

Figure 4: Pulley Alignment & Tension

Whenever belts

are removed or

installed, never force belts over pulleys

without loosening motor rst to relieve

belt tension.

Make sure inlets and approaches to the

unit are free from obstruction. To assure

maximum air movement, make sure ade-

quate supply air is available to ventilated

space.

Before putting fan into operation, com-

plete the following check list:

a. Turn off and LOCK OUT the power

source.

b. Make sure installation is in

accordance with manufacturer’s in-

structions.

c. Check and tighten all fasteners.

d. Spin centrifugal wheel to see

if rotation is free.

e. Check all set-screws and keys:

tighten if necessary.

f. Torqued set screws have a colored

Torque Seal mark indicating the cor-

rect torque has been applied.

g. Check belt or direct drive coupling

for alignment (use recommended

belt tension gauges).

h. Check belt for proper

sheave selection.

i. Make sure there is no foreign or

loose material in ductwork leading to

and from fan or in the fan itself.

j. Properly secure all safety guards.

k. Secure all access doors to fan

and ductwork.

l. Check line voltage with

motor nameplate.

m. Check wiring.

(On single phase mo-

tors, the terminal

block must be set up in accordance with

the nameplate instructions and/or wiring

diagram. This set up must match the line

voltage. If the motor is multi-speed or

multi-voltage, the winding leads must be

grouped and connected as shown on the

motor wiring diagram. The line voltage

must correspond with proper grouping

of motor leads. The wiring diagram must

be followed explicitly or serious motor or

starter damage will occur.) Don’t operate

at RPM higher than catalog.

The ventilator has been checked at the fac-

tory prior to shipment for mechanical noises.

If mechanical noises should develop:

a. Check rotating components

for adequate clearance (wheel align-ment pr

cedures are on page 7) and direction of rota-

tion. CCW looking from drive side.

b. Check proper belt tension and pulley

alignment.

c. Check installation and anchoring.

d. Check fan bearings.

Switch on electrical supply and allow fan to

reach full speed.

Check carefully for Correct rotation of the

centrifugal wheel.

Incorrect rotation

overloads motor

severely and results in serious motor dam-

age. To change rotation of three phase

units, interchange any 2 of the 3 line leads.

On single phase units, change the terminal

block set-up following the wiring diagram on

the motor.