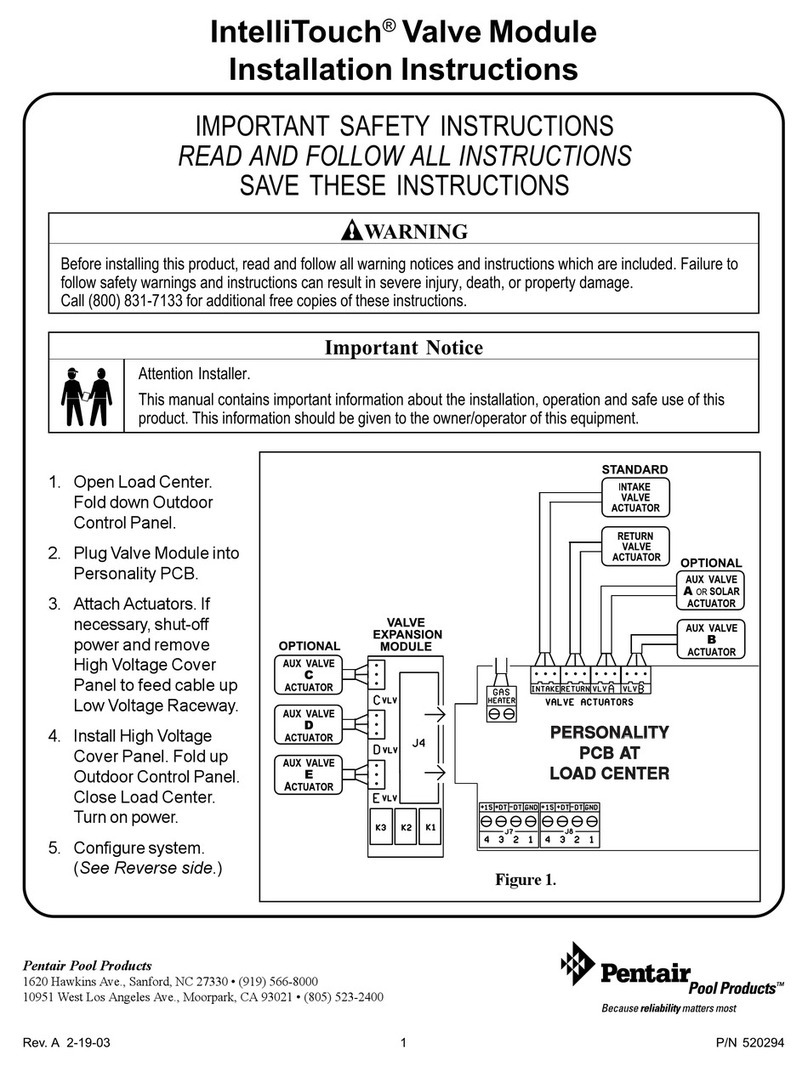

2-Way and 3-Way Diverter Valve and Check Valve

Installaton and Operation Instructions

Diverter Valve

The Pentair Water Pool and Spa®user adjustable diverter valve is designed to be used a DIVERTER valve, NOT a

BACKWASH valve.

The FullFloXF™ 2-Way and 3-Way Diverter valves can operated by hand or with a motorized valve actuator (such as

the CVA-24 by Pentair Water Pool and Spa®). 3-Way Diverter valves are used to divert incoming water flow (from pump,

etc.) applied at the INLET port to either of the different branches of the systems plumbing (filter, heater, solar

collectors, skimmer, etc.). 2-Way Diverter and Check valves are used to block the flow of water in one direction only.

The 2-Way and 3-Way Diverter valves can also be used to regulate (limit) water flow coming out of the valve by

adjusting the diverter mechanism covering a portion of the OUTLET port. All Diverter valves should ONLY be used with

the Diverter mechanism regulating or shutting off flow on the down stream (OUTLET) side of the flow.

Plumbing

The Diverter and Check valves are sized for use with 2-1/2” or 3” CPVC/PVC pipe fittings. 2-1/2” pipe can be plumbed

directly into the valve port’s socket, 3” plumbing requires an appropriate 3” (coupling or 90° elbow) slipped over the valve

port’s spigot. Can also be used with any size PVC plumbing with appropriate adapters

Note: Be cautious that no glue enters the inside of the valve body past the ports. The recommended pipe glue

to use is,WELD-ON

®

724 CPVC, GRAY or glue types such as WELD-ON

®

790

™

MULTI-PURPOSE SOLVENT

CEMENT.

SERIOUS BODILY INJURY OR DEATH CAN RESULT IF THE 3” VALVE IS NOT INSTALLED AND

USED CORRECTLY. INSTALLERS, POOL OPERATORS AND POOL OWNERS MUST READ THESE

WARNINGS AND ALL INSTRUCTIONS BEFORE INSTALLING THIS VALVE.

IMPORTANT NOTICE - Attention Installer: This Installation and Operation Instructions (“Instructions”) contains

important information about the installation, operation and safe use of the 3-inch pump. These Instructions should

be given to the owner and/or operator of this equipment. This 3” Valve is intended for use in swimming pool and

spa applications.

This valve must be installed by a qualified pool and spa service professional or plumber in accordance

with all applicable local codes and ordinances. Improper installation may create an electrical hazard

which could result in death or serious injury to pool users, installers, or others due to electrical shock, and may also cause

damage to property. Most states and local codes regulate the construction, installation, and operation of public pools and

spas, and the construction of residential pools and spas. It is important to comply with these codes, many of which directly

regulate the installation and use of this product. Consult your local building and health codes for more information.

2-Way & 3-Way Diverter Valve (2-1/2” Socket x 3” Spigot)

Figure 2. 3-Way Diverter Valve Ports

Port B (INLET)

(“INLET” typical common port)

Water flow into or out of valve.

Port C

Port A

Figure 1. 3-Way Diverter Valve

3” Pipe

3” Coupler

3” Pipe

2-1/2” Pipe

(Slip Fit)

Note: The diverter

valve “INLET”

(“common”) port

can be oriented

from any one of the

three ports

(see page 3)

FullFloXF™

DO NOT increase pump size; this may increase the flow rate through the system and exceed the maximum

flow rate stated on the drain cover. Exceeding the maximum flow rate stated on the drain cover could

result in death or serious injury to pool users and may also cause property damage.

1

OFF indicator

marks position of

CLOSED port