Operation Instructions

CADDY, CADWELD, CRITEC, ERICO, ERIFLEX, ERITECH and LENTON are registered trademarks of PENTAIR Corporation

TECHNICAL SUPPORT: IPPBPLUSCU_A 2 of 4 2016 PENTAIR

www.pentair.com

CONNECTIONS TO PIPE/VESSELS

For use with cast iron pipe or heavy casting meeting ASTM A47-84, A48-83, A126-84, A278-85, or A377-89. DO NOT USE ON

CAST IRON SOIL PIPE (ASTM A74-93). Evaluate possible effects of ERICO CADWELD PLUS connections to structural

members and thin-wall materials; vessels/piping systems that are pressurized, closed or containing (or having contained)

flammable / explosive / hazardous materials. Evaluation should be made prior to use, based on conditions of use and applicable

codes, and should incorporate as a minimum, effects of melt-through of hot material; structural/metallurgical effects of ERICO

CADWELD PLUS connections, pressure (temperature) build-up and fire/chemical decomposition hazards.

CONNECTIONS TO REBAR

Application of the ERICO CADWELD PLUS connection may have an effect on the rebar’s structural integrity. The rebar’s

chemistry and the location of the weld should be considered before making any welds to the rebar. For lapped rebar splices, it is

recommended that the connections be made near the bar end at an area of minimum stress. If ERICO CADWELD PLUS Rebar

Splices are used, the grounding connection can be made to the splice sleeve with minimal effect on the structural characteristics

of the splice.

SAFETY INSTRUCTIONS: All governing codes and regulations and those required by the job site must be observed. Always

use appropriate safety equipment such as eye protection, hard hat, and gloves as appropriate to the application.

SPECIFIC SAFETY RULES

DANGER! High voltage electrical shock hazard. Keep hands and body clear of the conductors while operating.

Failure to do so can result in death or serious injury.

WARNING! Operation and maintenance of the ERICO CADWELD PLUS Control Unit should only be performed by

qualified personnel.

CAUTION! Read, understand and follow all safety instructions prior to performing any ERICO CADWELD PLUS

connection. Refer to the ERICO CADWELD PLUS WELDING PROCEDURE, Instructions (IPX) prior to making any

ERICO CADWELD PLUS connection.

Electrical Safety. Do not abuse the lead. Never use the

lead to carry the Control Unit. Keep the lead away from

sharp edges or moving parts. Replace damaged leads

immediately. Damaged leads may create a safety hazard.

Control Unit Use and Care. If damaged, have the Control

Unit serviced before using. The Control Unit service must

be performed only by qualified repair personnel. Service or

maintenance performed by unqualified personnel may

result in a risk of injury. Follow the instructions in the

Maintenance section of this manual. Use of unauthorized

FUNCTIONAL DESCRIPTION

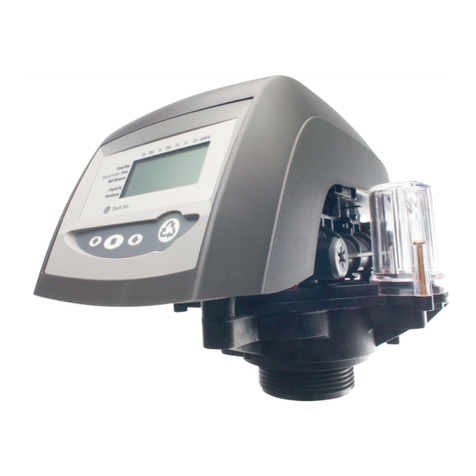

The ERICO CADWELD PLUS welding system replaces the

conventional method of using starting material and a flint

gun to ignite welding material to initiate the ERICO CADWELD

PLUS process. This is accomplished by using pre-sealed,

drop-in welding material crucible cup packages which are placed

into existing molds and using the ERICO CADWELD PLUS

Control Unit to discharge current into a pre-installed crucible

cup ignitor strip.

The ERICO CADWELD PBPLUSCU Control Unit uses

8 AA lithium batteries, a charging circuit, an output capacitor

parts or failure to follow Maintenance Instructions may

create a risk of shock or injury.

Storage. The Control Unit lead should be wrapped around

the case prior to storage. When storing Control Unit, store

the Control Unit in such a manner as to prevent accidental

push button OPERATE switch activation.

Avoid accidental activation. Be sure OPERATE switch

is not being pressed during insertion of ignition strip into

Control Unit termination clip.

and an electronic switch to initiate the discharge. The

charging commences once the OPERATE membrane

push button is pressed and held. The READY light

flashes to indicate charging is in process. If the

pushbutton is released, the charging ceases and the

capacitor discharges internally. In the event the lead

is not connected to the ERICO CADWELD PLUS

crucible cup ignitor strip, the capacitor discharges

internally. Once the output capacitor is fully charged

the READY light changes to steady state and then goes

out when the capacitor discharges into the crucible cup

ignitor strip to initiate the ERICO CADWELD PLUS

process.