WARNING

Always check equipment for

proper operation before each

use, making sure safety devices

are in place and operating

properly. DO NOT alter or modify

any part of the equipment as this

may cause amalfunction and

result in serious bodily injury.

ATTACHING HYDRAULIC

MOTOR TO PUMPTUBE

1. Tightly attach Tie Rods (Item 38) to

the Mounting Plate (Item 37). (Use

short threaded end of tie rods).

2. Mount hydraulic motor on top of

pumptube outlet body and tightly

connect pumptube coupling nut to

Piston Rod (Item 29).

3. Hand tighten tie rods to the pumptube

with four Nuts (Item 39) supplied with

hydraulic motor.

4. Connect hydraulic supply and return

lines and slowly cycle pump several

times, using only enough pressure to

operate the pump without stalling.

NOTE: Air in the hydraulic motor

may cause slow or erratic shifting

during the first few cycles after

connecting the hydraulic lines.

5. Stop the pump on an “up” stroke and

tighten the four nuts to securely fasten

the hydraulic motor to the pumptube.

WARNING

WARNING

Toreduce therisk ofserious

bodily injury orproperty damage,

NEVER exceed themaximum

fluid working pressure of he

lowest rated system component.

OPERATING PRECAUTIONS

•Use Lincoln replacement parts to

assure compatible pressure rating.

•HEED ALL WARNINGS.

•Be sure material hoses and other

•DO not operate hydraulic motor

continuously at speeds in excess of

75 cycles per minute.

•Disconnect hydraulic line from

hydraulic motor when system sits

idle for long periods of time.

•SERVICING. Before servicing hy-

draulic motor be sure to carefully

bleed pressure off of the system and

disconnect the hydraulic supply

lines.

DISASSEMBLY

before beginning disassembly.

Tools Required

1/8” Hex Key

3/16“ Hex Key

1/4” Hex Key

9/16“ Open End Wrench

3/4” Open End Wrench

1-1/4’ Open End Wrench

1” Hex Socket Wrench

Procedure

1.

Remove Eyebolt (Item 1) from top of

hydraulic motor.

2. Remove Washer (Item 2), Cover

(Item 3) and Spacer (Item 4).

3. Remove four Tie Rods (Item 38).

4. Remove four Screws (Item 5) and

remove manifold subassembly from

cylinder subassembly.

5. Remove four Screws (Item 40) to

separate Upper Manifold (Item 6)

from Lower Manifold (Item 13).

6. Remove O-rings (Items 8, 9&10)

from Lower Manifold (Item 13).

7. Remove Cartridge Valve (Item 12)

from Lower Manifold (Item 13).

8. Remove six O-ring Plugs (Items 7&

14) from Lower Manifold (Item 13).

9. Remove Cartridge Valve (Item 11)

components are able to withstand from Upper Manifold (Item 6).

hydraulic pressures.

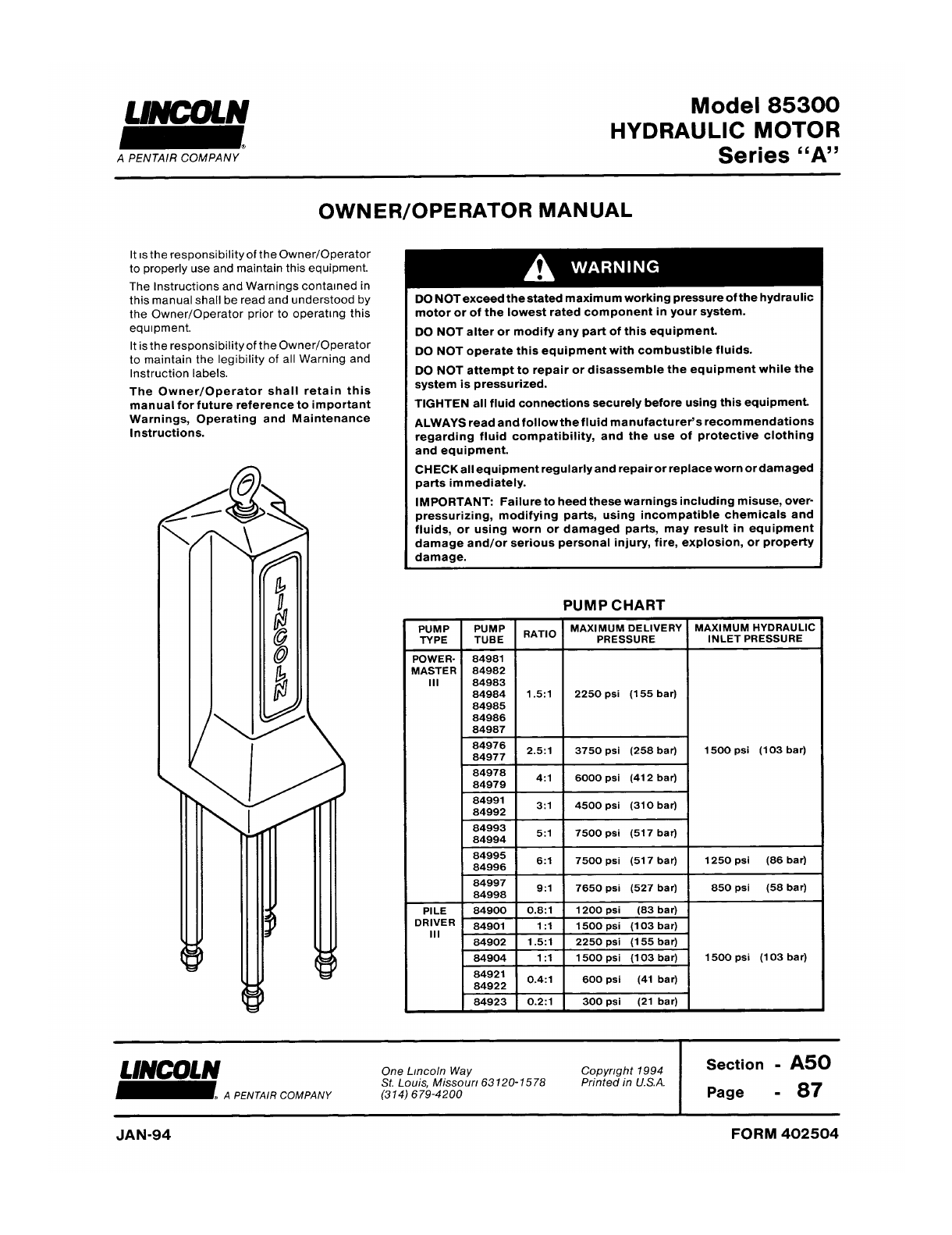

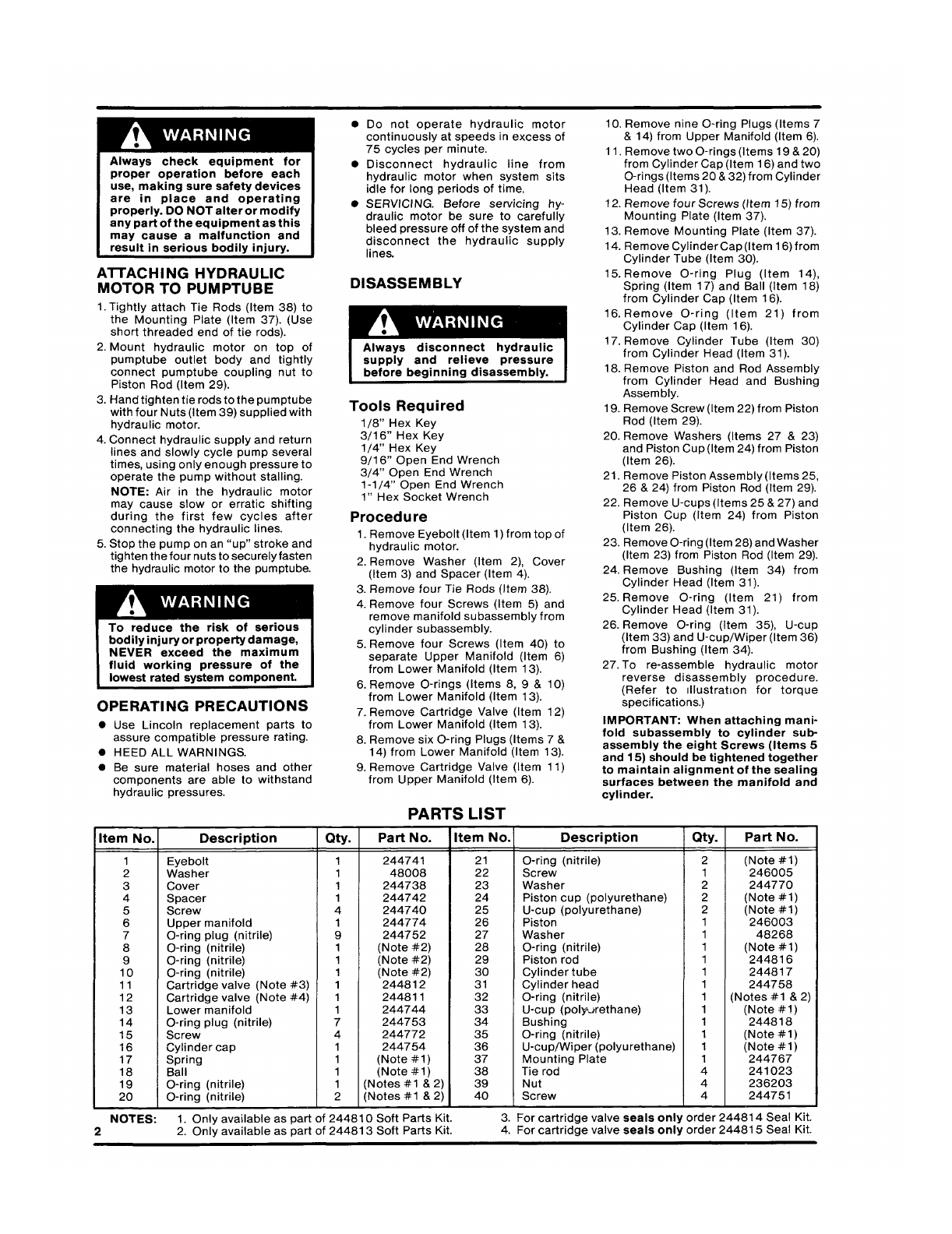

PARTS LIST

10. Remove nine O-ring Plugs (Items 7

&14) from Upper Manifold (Item 6).

11. Remove two O-rings (items 19 &20)

from Cylinder Cap (Item 16) and two

O-rings (Items 20&32) from Cylinder

Head (Item 31).

12. Remove four Screws (Item 15) from

Mounting Plate (Item 37).

13. Remove Mounting Plate (Item 37).

14. Remove Cylinder Cap(Item 16) from

Cylinder Tube (Item 30).

15. Remove O-ring Plug (Item 14),

Spring (Item 17) and Ball (Item 18)

from Cylinder Cap (Item 16).

16. Remove O-ring (Item 21) from

Cylinder Cap (Item 16).

17. Remove Cylinder Tube (Item 30)

from Cylinder Head (Item 31).

18. Remove Piston and Rod Assembly

from Cylinder Head and Bushing

Assembly.

19. Remove Screw (Item 22) from Piston

Rod (Item 29).

20. Remove Washers (Items 27 &23)

and Piston Cup(Item 24) from Piston

(Item 26).

21. Remove Piston Assembly (Items 25,

26 &24) from Piston Rod (Item 29).

22. Remove U-cups (Items 25&27) and

Piston Cup (Item 24) from Piston

(Item 26).

23. Remove O-ring (Item 28) and Washer

(Item 23) from Piston Rod (Item 29).

24. Remove Bushing (Item 34) from

Cylinder Head (Item 31).

25. Remove O-ring (Item 21) from

Cylinder Head (Item 31).

26. Remove O-ring (Item 35), U-cup

(Item 33) and U-cup/Wiper (Item 36)

from Bushing (Item 34).

27. To re-assemble hydraulic motor

reverse disassembly procedure.

(Refer to Illustration for torque

specifications.)

IMPORTANT: When attaching mani-

fold subassembly to cylinder sub-

assembly the eight Screws (Items 5

and 15) should be tightened together

to maintain alignment of the sealing

surfaces between the manifold and

cylinder.

tern No. Description Qty. Part No. Item No. Description Qty. Part No.

1Eyebolt 1244741 21 O-ring (nitrile) 2

2Washer 148008 22 Screw (Note #1)

1 246005

3Cover 1244738 23 Washer 2244770

4Spacer 1 244742 24 Piston cup (polyurethane) 2

5Screw 4(Note #1)

244740 25 U-CUP (polyurethane) 2

6Upper manifold 1244774 26 (Note #1)

Piston 1

7O-ring plug (nitrile) 9244752 27 246003

Washer 1 48268

8O-ring (nitrile) 1(Note #2) 28 O-ring (nitrile) 1

9O-ring (nitrile) 1(Note #2) 29 (Note #1)

Piston rod 1244816

10 O-ring (nitrile) 1(Note #2) 30 Cylinder tube 1 244817

11 Cartridge valve (Note #3) 1244812 31 Cylinder head 1244758

12 Cartridge valve (Note #4) 1244811 32 O-ring (nitrile) 1

13 Lower manifold 1244744 (Notes #1 &2)

33 U-cup (polyurethane) 1(Note #1)

14 O-ring plug (nitrile) 7244753 34 Bushing 1 244818

15 Screw 4244772 35 O-ring (nitrile) 1

16 Cylinder cap 1244754 36 (Note #1)

U-cup/Wiper (polyurethane) 1

17 Spring 1(Note #1) 37 (Note #1)

Mounting Plate 1

18 Ball 1(Note #1) 38 244767

Tie rod 4 241023

19 O-ring (nitrile) 1(Notes #1 &2) 39 Nut 4 236203

20 O-ring (nitrile) 2(Notes #1 &2) 40 Screw 4 244751

NOTES: 1.Only available as part of 244810 Soft Parts Kit. 3. For cartridge valve seals only order 244814 Seal Kit.

22. Only available as part of 244813 Soft Parts Kit. 4. For cartridge valve seals only order 244815 Seal Kit.