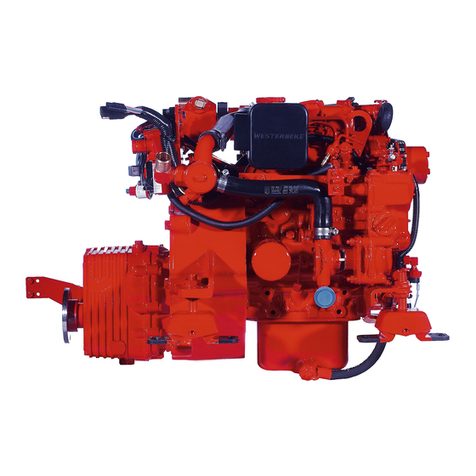

A

NEW

COMPACT

DIESEL,

52

HP

FOR

YACHTS

UP

TO

55

FT

.

,

....

.

..

',

I '

. I

,.

4>l.

....

,'"

II

._

-d

CONSTRUCTION

.- ",

-,

....

t '...

..

...,

-.

...

....

" ~

---,-~".C".~='

''

,

''

...

!Sl''

,

..

"

~"

..

~

.

I.

Cy

linder H

ea

d:

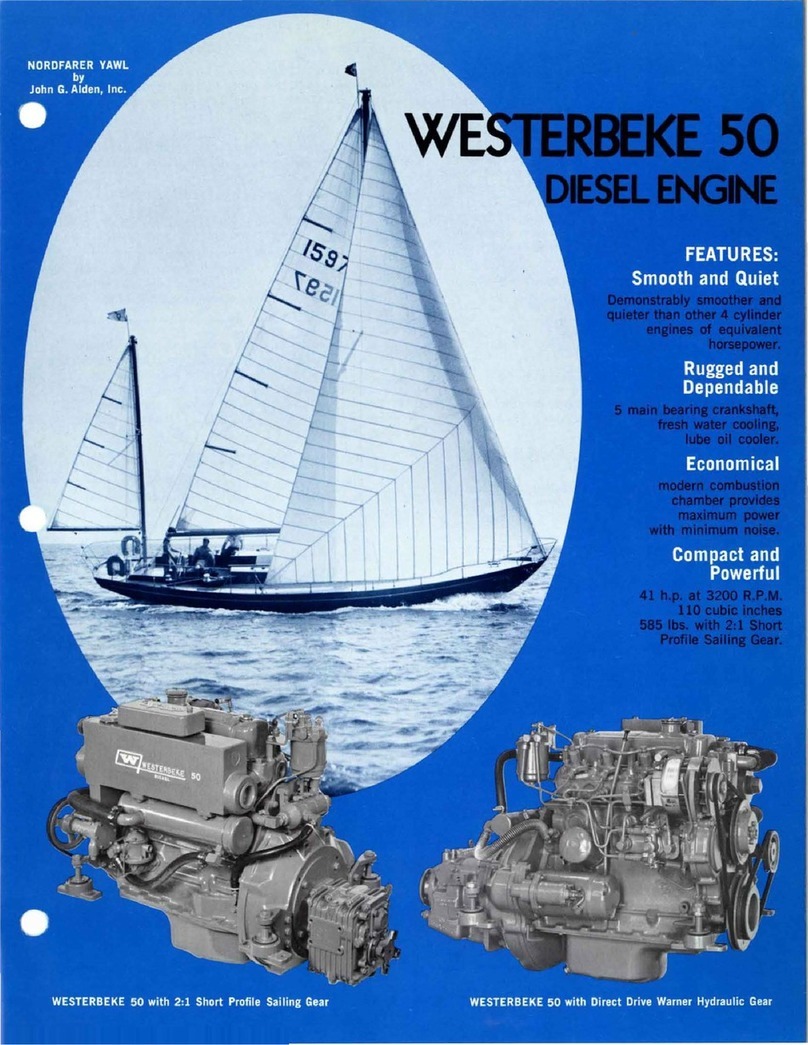

The

special cast-iron cylinder head

is

precision-cast by the shell moulding process and then soft-gas-

nitrided for increased durability.

The

intake and exhaust ports

are arranged for crossflow to raise the intake and exhaust effi-

ciency.

The

swirl type precombustion chamber

is

used.

2.

Cy

linder Block: Weight reduction achieved by technologies

of

thin wall ductile cast iron and half skirt.

The

water rail is

designed

to provide uniform distribution

of

coolant to the cylin-

der

head.

The

cylinder liner is

of

the dry type

of

high-

pho

sphorus cast iron, which is given special honing to provide

quick

seating. and good oil retention, thus increasing wear

re

sistance.

3. Crank Mechanism:

The

forged crankshaft

is

supported by 5

bearings.

The

autothermatic piston

of

Lo-Ex alloy has a sheet

metal

cast

in its skirt so as to hold the thermal expansion

of

the

piston, thereby making

it

possible to

le

ssen the piston clearance.

The

piston pin is offset by 0.5rnm. All these improvements

ensure

quiet operation from l

ow

to high speeds.

4.

Va

lve Mechanism:

O.H.V.

Both intake and exhaust valves

are

of

rotation type for higher durability

of

the valve seat.

Coupled

with a friction

gear

with one extra tooth, the timing

ge

ar

train is intended to eliminate the backlash at the time

of

gear

engagement

to reduce gear noise.

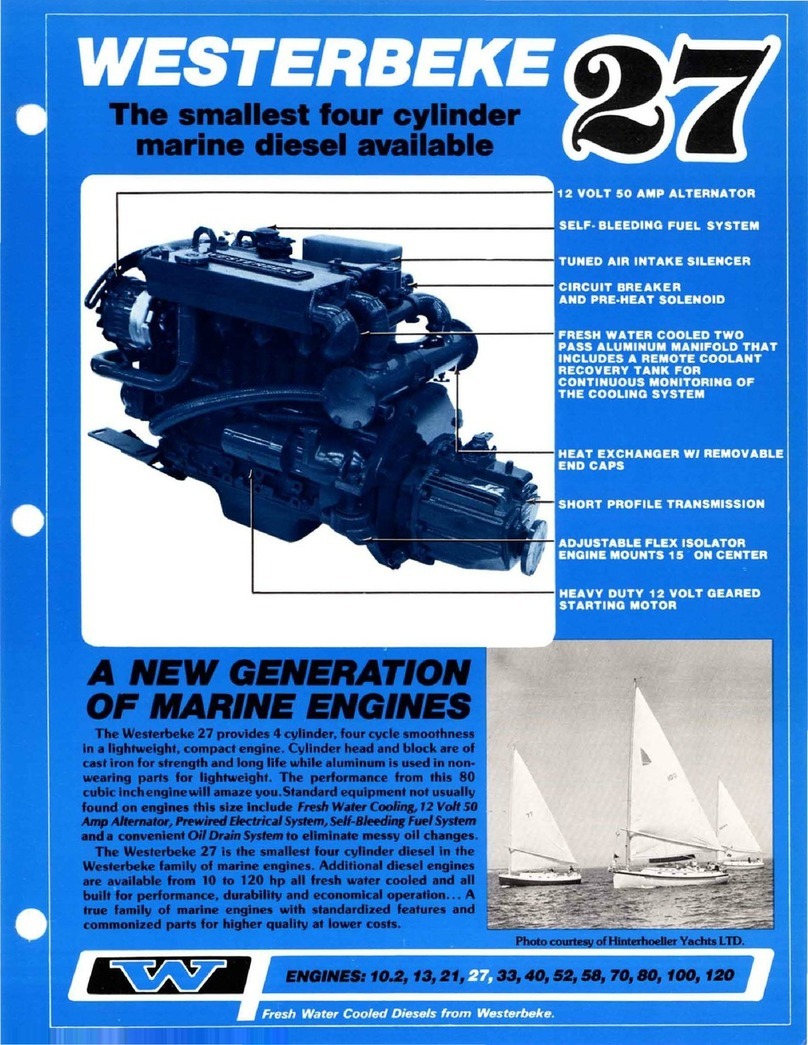

5. Intake and Exhaust System: The intake manifold is

of

inde-

pendent branch type for higher intake efficiency.

6. Fuel System:

The

fuel injection pump is a Bosch VE type

distributor

pump,

small

in

size and light

in

weight, contributing

t

oward

noise reduction. Since fuel can

be

cut with the solenoid

va

lve built

in

the pump, the engine operation can be stopped

by

turning

off

the ignition switch.

SPEClFlCA

TlONS

Number

of

Cylinders & Arrangement

.........

4 in-line

Cylinder

Bore & Stroke

...............

3.50

in

. x 3.51

in

.

Displacement

............................

134

.8 C.

l.D.

Comp

ression Ratio

.............

.

•.............

. 21: I

Comb

us

ti

on

Chamber

.......................

Swirl Type

Firing

Order

..........

.

.................

1-3-4-2

Injection Pump

...........

.

......

Bosch

Di

stributor Type

Governor

...................

Mechanical (Bui

lt

in

Pump)

Lubrication Method

.................

Pressure Feed Type

Cooling

Method

....................

Fresh WaterCooled

Cold

Starting Aid

.......

.

..............

Glow Plug

Electrical System Voltage

......................

12

Volts

Dry

W

eig

ht

of

Engine (w/2: I Trans.)

............

. 627

Ibs

.

Power

Take-off

...............

Various Crankshaft Pulleys

.>.

.

..

1 .

"

~

~

.

~

"

, "

..........

j-t_

...

. U' I

1

1".·

••

,

;'"

'

....

"-

1'-

_'r

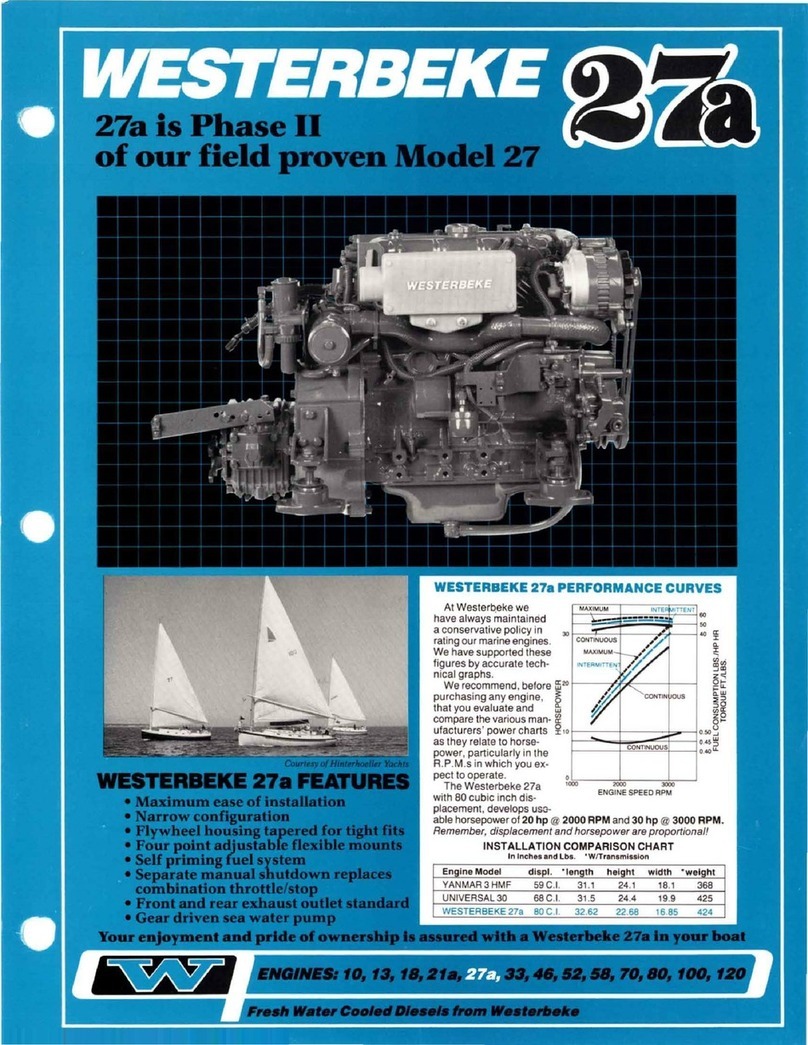

PERFORMANCE

DATA

Maximum

Torque

.........

.

One

hour

Rating

•

•

»

=

~

.

~

::1

»

0

~

•

"

PERFORMANCE

CURVE

1IfI[,....~TIIIG

r

~

~

.t:

/--.......

n

i3

.~

.-

i'-

/'

~

~

~

L

~

'$I'

~

~

.41

~

~

D"~

1.8

,

..

... ...

-

~

ENGINE

SPEED

RPM

~

93.3

ft.

Ib

./25oo

r.p.m.

35

HP

/2ooo r.

p.m.

, 53 HP/3ooo

r.p.m

..

66 HP/4ooo r.p.m.

Continuous Rating

30

HP/2

ooo

r.p.m

..

45 HP/3ooo r.p.m

..

56 HP/4ooo r.p.m.

Typical Fuel

Co

n

sump

ti

on Rate

.........

063

US

gal/HP/hr

Typical Fuel Consumption Rate

at

2500 RPM

when wheeled

to

tum 3000 RPM

Capacity

of

Lubricant

...

.

......

.

Capacity

of

Coolant

.......

.

STA 'DAR!>

EQL

'

IPMENT

Clutch and

2:

I Reduction Gear (R.H. Propeller)

Adjustable flexible mounts on

18"

centers

Fresh watercooling system

12

volt 55 anlpere alternator

Clutch and throttle

co

ntrol brackets

Glow

plug

co

ld starting a

id

Engine pre-wired with single 8 pin connee

lOr

Electric shut

off

Operators manual

Alarm, l

ow

o

il

pressure, high water temperature

Water

In

jected Exhaust Elbow

Lube Oil Drain Hose

I.7 US gal/hr

5.3

qts.

10

.5 qts.

Flowcontroller-foreasy connec

ti

on

of

domestic hot waterheater

OI'TlONAL

EQUIPi\IE:'IiT

Various accessory front pulleys

Hydro-Hush Muffler

Sea

Wat

er

Strainer

Alternator Output Splitter

Additional 55 amp. alternator

Primary 90 amp. alternator

1

8/20/22

v,

" mounting centers

Remote mounting lube o

il

tilter

Five function Electric

In

strument Panel including Hour Meter

and

Ta

chometer

A wide variety

of

manual and hydraulic trans

mi

ssions are avail-

able

in

va

ri

ous reduction

gea

rs and vee drives.

Front exhaust outlet for Vee Drive applications

CALL

YOUR

WESTERBEKE

REPRESENTATIVE

[

___

~

l

OR

CONTACT

THE

...

J.

H.

WESTERBEKE

CORP.

Manne NLP 6/6217500 Prlnled In

US

A

Avon

Industrial Park, Avon,

MA

02322,

(617)

588-

7700

Cable:

Westcorp,

Avon, Telex:

92-4444

(

(

(