English – 5

FUEL HANDLING

General

Fuel

Gasoline

• Use good quality unleaded gasoline.

• The lowest recommended octane grade is 87

((RON+MON)/2).If you run the engine on a lower octane

grade than 87 so-called knocking can occur.This gives

rise to a high engine temperature and increased bearing

load, which can result in serious engine damage.

• When working at continuous high revs a higher octane

rating is recommended.

Environment fuel

The use of environmentl fuel (alkylate fuel), or environment

fuel for four-stroke engines blended with two-stroke oil as set

out below is recommended.

Ethanol blended fuel, E10 may be used (max 10% ethanol

blend).Using ethanol blends higher than E10 will create lean

running condition which can cause engine damage.

Two-stroke oil

•For best results and performance use HUSQVARNA two-

stroke engine oil, which is specially formulated for our air-

cooled two stroke-engines.

• Never use two-stroke oil intended for water-cooled

engines, sometimes referred to as outboard oil (rated

TCW).

• Never use oil intended for four-stroke engines.

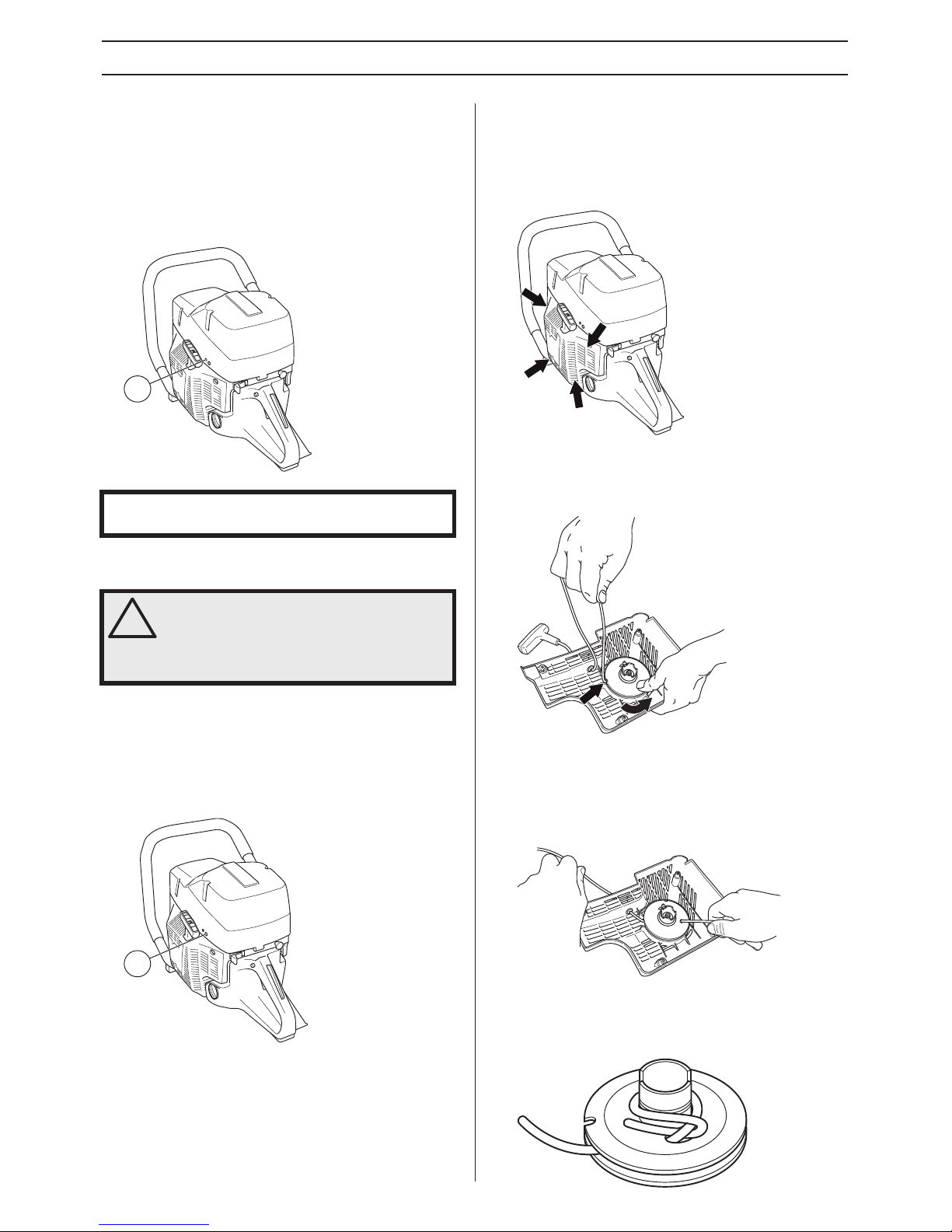

Mixing

• Always mix the gasoline and oil in a clean container

intended for fuel.

• Always start by filling half the amount of the gasoline to be

used.Then add the entire amount of oil. Mix (shake) the

fuel mixture.Add the remaining amount of gasoline.

• Mix (shake) the fuel mixture thoroughly before filling the

machine’s fuel tank.

• Do not mix more than one month’s supply of fuel at a time.

Mixing ratio

•1:50 (2%) with HUSQVARNA two-stroke oil or equivalent.

• 1:33(3%) with oils classJASOFB or ISO EGB formulated

for air-cooled, two-stroke engines.

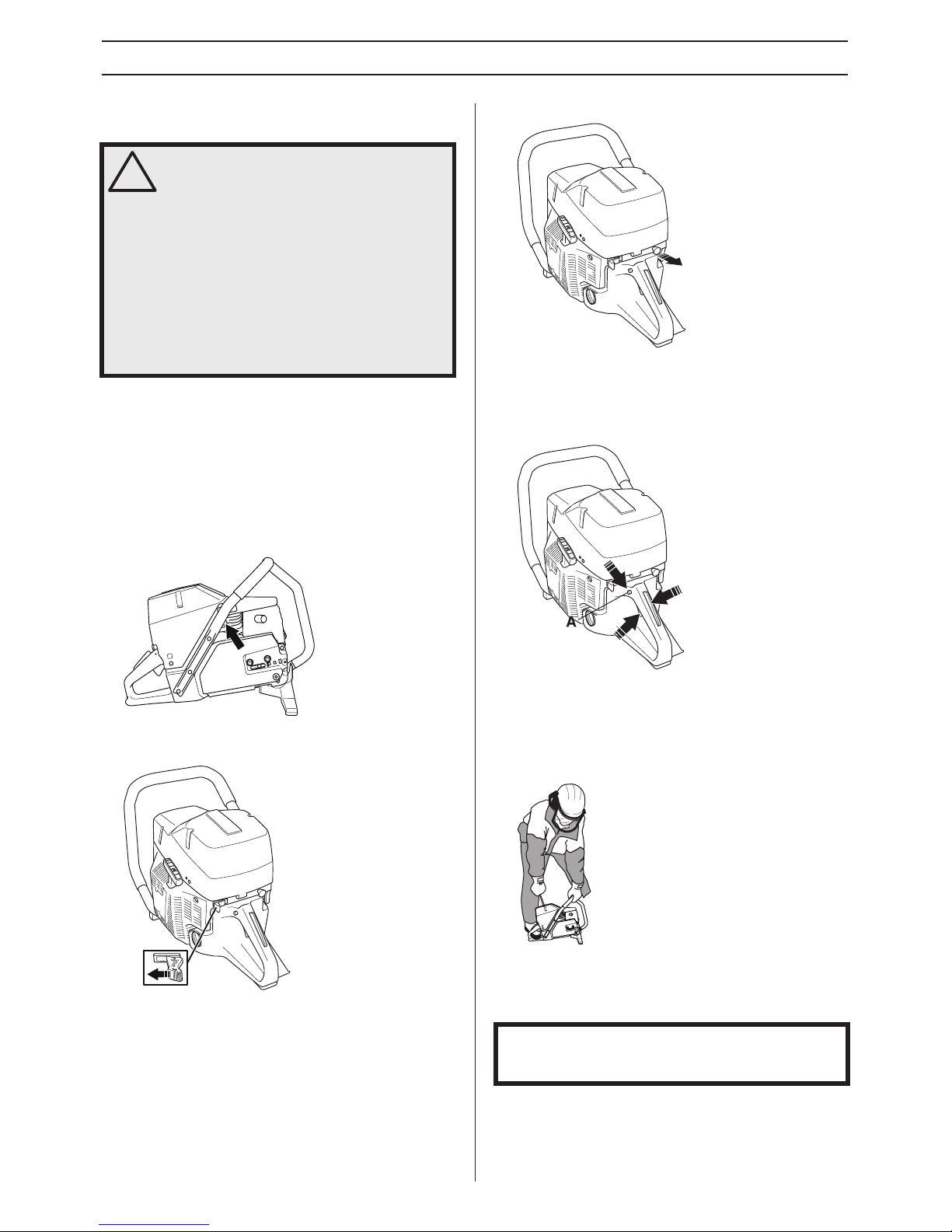

Fueling

Never start the machine:

• If you have spilled fuel or chain oil on the machine.Wipe

off the spillage and allow remaining fuel to evaporate.

• If you have spilled fuel on yourself or your clothes, change

your clothes.Wash any part of your body that has come in

contact with fuel. Use soap and water.

• If the machine is leaking fuel. Check regularly for leaks

from the fuel cap and fuel lines.

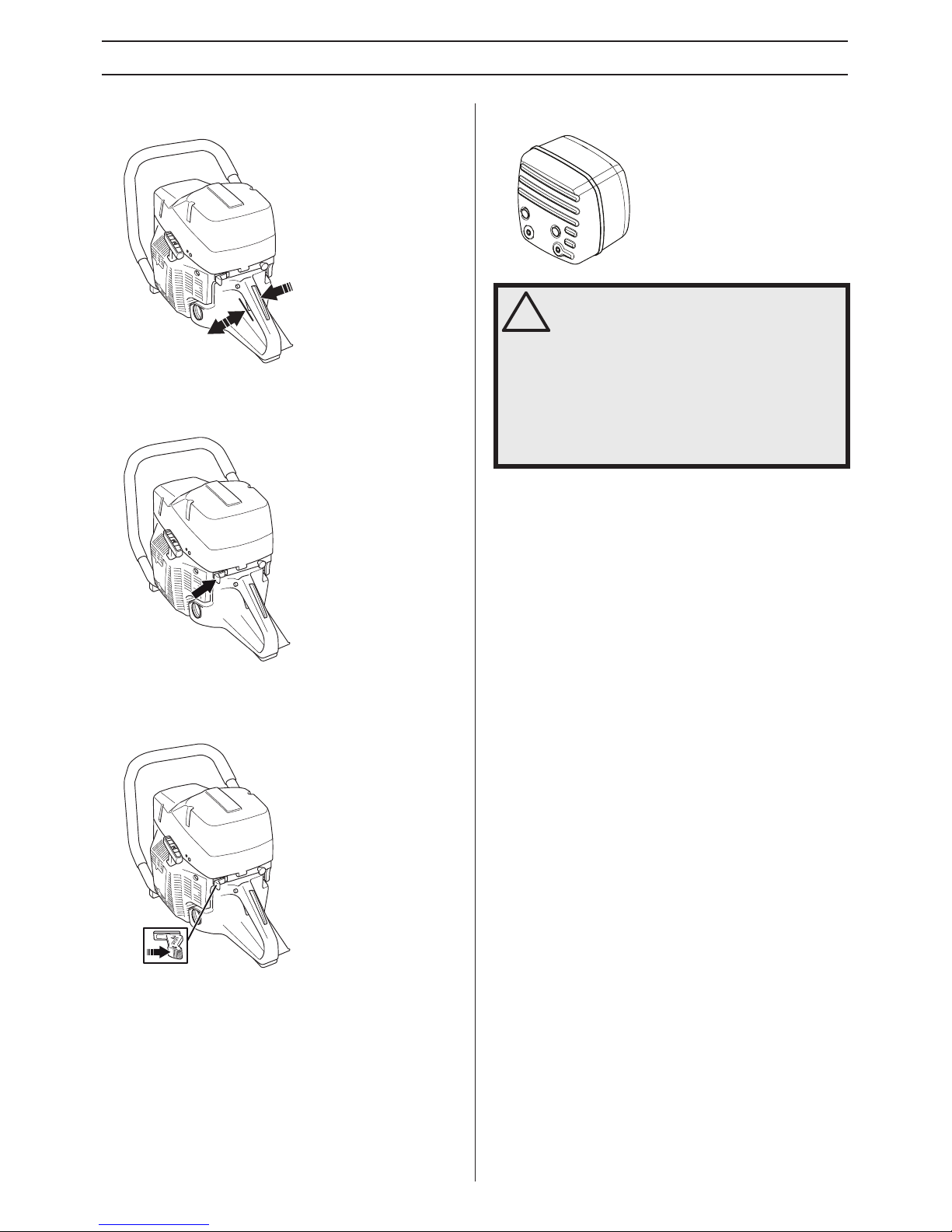

Transport and storage

•Store and transport the machine and fuel so that there is

no risk of any leakage or fumes coming into contact with

sparks or naked flames, for example, from electrical

machinery, electric motors, electrical relays/switches or

boilers.

• When storing and transporting fuel always use approved

containers intended for this purpose.

Long-term storage

• When storing the machine for long periods the fuel tank

must be emptied.Contact your local gas station to find out

where to dispose of excess fuel.

!

WARNING! Running an engine in a confined

or badly ventilated area can result in death

due to asphyxiation or carbon monoxide

poisoning. Use fans to ensure proper air

circulation when working in trenches or

ditches deeper than one meter (3 foot).

Fuel and fuel fumes are highly inflammable

and can cause serious injury when inhaled

or allowed to come in contact with the skin.

For this reason observe caution when

handling fuel and make sure there is

adequate ventilation.

The exhaust fumes from the engine are hot

and may contain sparks which can start a

fire. Never start the machine indoors or near

combustible material!

Do not smoke and do not place any hot

objects in the vicinity of fuel.

NOTICE! The machine is equipped with a two-stroke

engine and must always been run using a mixture of

gasoline and two-stroke engine oil. It is important to

accurately measure the amount of oil to be mixed to ensure

that the correct mixture is obtained.When mixing small

amounts of fuel, even small inaccuracies can drastically

affect the ratio of the mixture.

Gasoline, litre Two-stroke oil, litre

2% (1:50) 3% (1:33)

50,10 0,15

10 0,43/0,20 0,6/0,30

15 0,6/0,30 0,45

20 0,40 0,60

!

WARNING! Always stop the engine and let it

cool for a few minutes before refuelling.The

engine should be switched off, and the stop

switch in STOP position.

When refuelling, open the fuel cap slowly so

that any excess pressure is released gently.

Clean the area around the fuel cap.

Tighten the fuel cap carefully after refuelling.

Negligence may lead to the start of a fire.

Move the machine at least 10 ft (3 m) from the

refuelling point before starting it.