2

General

Information

Attention:

This manual contains important

information for the safe use

of this product. Read this

manual completely and do not

throw away. Reasonable care

and safe methods should be

practiced. Check local codes and

requirements before installation.

Warning: Before handling pumps

and controls, always disconnect

the power first. Do not smoke or

use sparkable electrical devices

or flames in a septic (gaseous) or

possible septic sump.

Unpacking Panel:

When unpacking the unit, check

for concealed damage. Claims

for damage must be made at

the receiving end through the

delivery carrier. Damage cannot

be processed from the factory.

CALIFORNIA PROPOSITION

65 WARNING:

This product and

related accessories contain

chemicals known to the

State of California to cause

cancer, birth defects or other

reproductive harm.

Panel

Installation

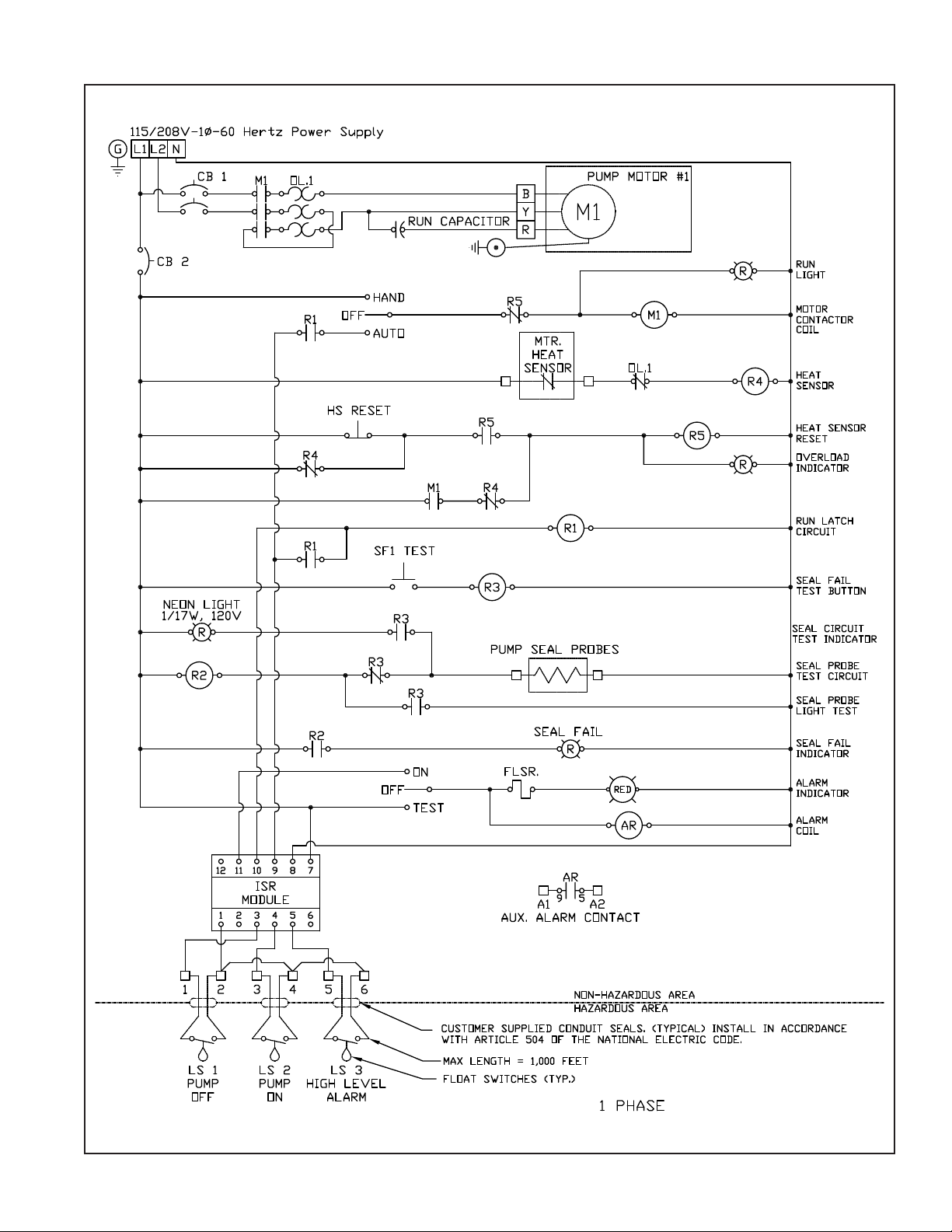

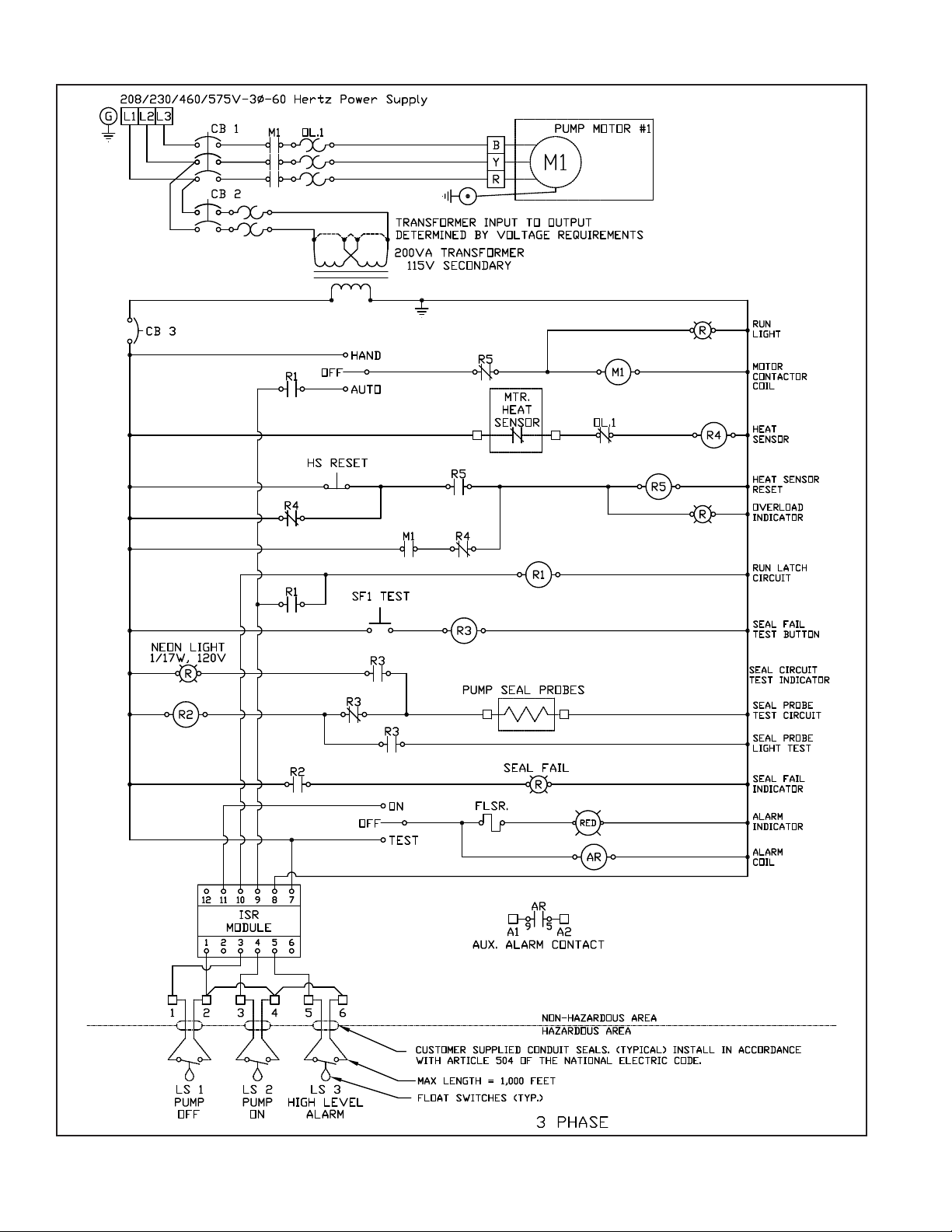

Electrical Connections:

Panel Opening – Wiring: The

enclosure opening for intrinsically

safe wires must not be used for

non-intrinsically safe wiring.

This is to be the only opening in

the intrinsically safe area of the

enclosure. If this is not done, the

UL Listing for the control panel

will be void.

Electrical Connections:

The contractor must conform

to the latest requirements of the

National Electrical Code. All

conduit and cables shall have

conduit per NEC Code NFPA

#70, where conduit and cable

leave the hazardous locations.

Prior to conducting any

installation, repair or service with

regard to the control panel, refer

to the schematic appropriate for

that panel. The schematic will

provide guidance with regard

to terminal block connections.

Electrical ratings are indicated on

the schematic for terminal blocks

used in interfacing with controls

remote from the control panel. If

these ratings are violated, the UL

Listing for the control panel will

be void.

Make the Following Electrical

Connections:

Connect the pump heat sensor

and seal failure leads to the

appropriate terminal blocks in

the non-intrinsically safe area

outside the barrier in the control

panel. Connect all the float

control leads to the appropriate

panel terminal blocks in the

intrinsically safe area within

the barrier in the control panel.

If guaranteed submergence of

the pumps is critical to this

installation, contractor must

be very careful in locating the

floats at the proper elevations.

The maximum distance between

the control panel and the floats

is the lesser of 300 feet or the

maximum distance recommended

for the pump.

Connect the pump leads to the

overload relay on the control

panel. When connecting the

pump leads it is very critical

that the proper sequence

be maintained.

On single-phase pumps, the

white, black and red pump

leads must be connected to the

pump terminal blocks in the

panel exactly as shown on panel

markings and on the schematic.

Note: Pump will run only if leads

are connected as shown.

On three-phase pumps, ensure

proper phase sequence while

connecting to the overload relay

in the control panel. Incorrect

phase sequence will result in the

reverse rotation of the pump.

Note: Make sure pump ground

wire is connected to the panel

pump ground lug.

Before connecting power to

the control panel, make sure all

control switches (ex. H-O-A

switch) and protective devices

(ex. breakers) are in the Off

position. Now connect power to

main power terminal blocks or

the circuit breaker as directed

by the schematic. Control panel

must be grounded properly per

NEC and/or local codes. To

facilitate this, a ground lug is

provided on the control panel.

Panel Check List

Check List:

Check junction box for moisture.

Moisture may cause chattering of

relays/contactors.

Check O/L relay settings and

verify reset mode.

With H-O-A switch(s) in Off

position, energize power to panel.

Check voltage to the panel and at

secondary of control transformer

using a voltmeter.

Check float operation and

response of control panel

to the float operation. For

sequence of operation refer to

design specification.