7

Pump and driver should be located in an area that will

permit periodic inspection and maintenance. Head and

access room should be provided and all units should be

installed in a dry location with adequate drainage.

Foundation

Pump foundations should have a level surface and be of

sufficient mass to prevent vibration and form a permanent

rigid support. The most satisfactory foundations are

concrete with anchor bolts of adequate size imbedded in the

foundation in pipe sleeves with an inside diameter

2-1/2 times larger than the bolt diameter which will allow for

final accurate positioning of the unit. Recommended anchor

bolt design is available from the factory.

INSTALLATION

General

Crushing hazard if pump drops. Use

appropriate lifting equipment to raise the pump. Do not try to

pick up the complete unit by the driver eye bolts or a pump

shaft eyebolt. The bolts may fail and drop the pump.

NOTICE: Pump and driver alignment should be checked

throughout the piping and grouting procedures. Once piping

connections have been made and grouting completed,

alignment corrections are difficult.

Grouting

When alignment is correct, the unit should be grouted using

a high grade non-shrinking grout. The base is designed to

be completely filled with grout.

NOTICE: Damaging vibration may result if the baseplate is

not solidly in contact with the grout bed.

Do not fill the anchor bolt pipe sleeves with grout.

If leveling devices are used, make sure they are not

imbedded in grout. Provide access in the grout to the

leveling devices (if used) so that they can be backed off or

removed after the grout has cured.

Allow the grout to fully cure. Back off leveling nuts (if used)

and remove shims and/or wedges. Firmly tighten the

foundation bolts so the base is solidly against the grout

bed. All pockets and/or holes left by removal of leveling

devices are to be filled with grout. Recheck alignment

before connecting the piping.

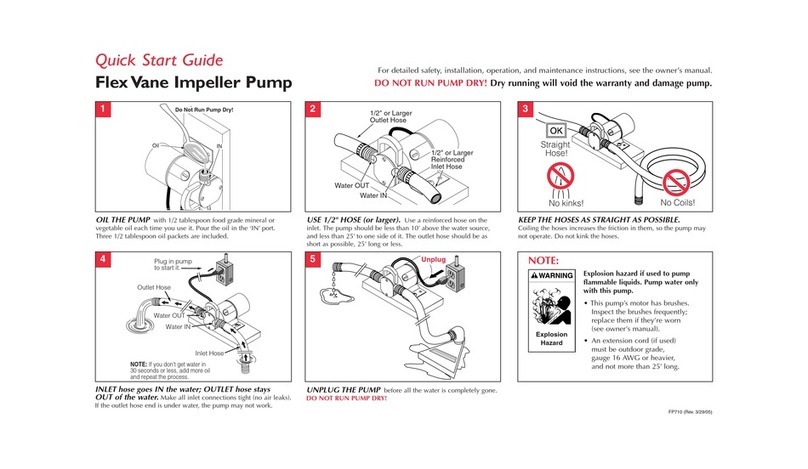

Piping

NOTICE: All piping connections must be made with the pipe

in a free supported state, and without the need to apply

vertical or side pressure to obtain alignment of the piping

with the pump flange.

All piping should be independently supported near the

pump so the pipe strain will not be transmitted to the pump

casing. Weight of the pipe and contained liquid must be

considered in support design. Suction and discharge

piping should be one or two sizes larger than the pump

suction and discharge sizes, especially where piping is of

considerable length. Flexible joints installed in the piping

must be equipped with tension rods to absorb piping axial

thrust.

Suction pipe must be airtight and sloped upward to

the pump flange to avoid air pockets which will impair

satisfactory pump operation. Discharge pipe should be as

direct as possible with a minimum of valves to reduce pipe

friction losses.

A check valve and closing valve should be installed in the

discharge line and a closing valve in the suction line. The

check valve, between the pump and closing valve, protects

the pump from water hammer and prevents reverse rotation

in the event of power failure. Closing valves are used in

priming, starting and when the pump is shut down. Pumps

must never be throttled by use of a valve in the suction line.

Auxiliary Piping Connections

In addition to primary piping connections, your pump may

require connections to the baseplate drain, discharge

pressure gauges or mechanical seals. All these connections

should now be installed. (Refer to Mechanical Seal section

of this manual.)

NOTICE: For satisfactory pump operation and life, auxiliary

pipe lines must be kept clean.

Rotation

Before connecting the motor to the pump, bump start the

motor and verify that rotation is in the proper direction.

Correct pump rotation is indicated by a directional arrow on

the pump casing.

Vibration and Noise Levels

After installation is complete and the pump is put into normal

service, a baseline measurement of noise and vibration

levels should be made for future reference. Periodic checks

should be made, as changes in either of these could

indicate problems. Early detection can save expensive

repairs and downtime. Refer to “Troubleshooting” for simple

causes and remedies.

Vibration and noise level measurements should be made

with the equipment in its normal operating mode, with no

unusual background noise present.

Leveling of the Pump

Lower the unit onto the foundation and position the base so

the anchor bolts are aligned in the middle of the holes in the

base. Disconnect the coupling halves.

Set the base on metal shims or metal wedges placed

directly under the part of the base carrying the greatest

weight, and spaced close enough to give uniform support

and stability.

Adjust the metal shims or wedges until the shaft of the

pump and driver are level. Make sure that all shims or

wedges fit firmly between the foundation and the base.

If leveling nuts are installed on the anchor bolts and are

used for alignment, follow the same procedure as with

shims or wedges. Support the base with additional shims or

wedges if necessary. Make sure that all nuts and shims are

in firm contact with the base.

Tighten the foundation bolts snugly, but not too firmly, and

recheck the shafts for being level before grouting. Motor

and pump shafts should also be in close alignment prior to

grouting. If not in close alignment, determine the cause for

misalignment and correct. Refer to the Grouting section.

NOTICE: Pump and driver alignment should be checked

throughout the piping and grouting procedures. Once piping

connections have been made and grouting completed,

alignment corrections are difficult.

Coarse Coupling Alignment

Risk of entrapment by rotating couplings.

Install guards before starting the pump. Check safety

codes, and always install protective guard or shield as

required by the various federal, state and local laws and the