2

GENERAL INFORMATION

This manual contains important information for the safe use of this

product. Read this manual completely before using this product and

refer to it often for continued safe product use. DO NOT THROW

AWAY OR LOSE THIS MANUAL. Keep it in a safe place so that

you may refer to it often.

Unpacking Pump:

Remove pump from carton. When unpacking unit, check for

concealed damage. Claims for damage must be made at the receiving

end through the delivery carrier. Damage cannot be processed from

the factory.

PUMP CAUTIONS AND WARNINGS

1. WARNING: Before handling these pumps and controls, always

disconnect the power rst. Do not smoke or use sparkable

electrical devices or ames in a septic (gaseous) or possible

septic sump.

2. WARNING: Risk of Electrical Shock – This pump is supplied

with a grounding conductor and grounding-type attachment plug.

To reduce risk of electrical shock, be certain that it is connected

only to a properly grounded, grounding-type receptacle.

• Septic tank to be vented in accordance with local plumbing

codes.

• DO NOT remove cord or strain relief. DO NOT connect

conduit to pump. Electrical installations shall be in accordance

with the National Electrical Code and all applicable local

codes and ordinances.

• A septic sump condition may exist and if entry

into sump is necessary, then (1) provide proper

safety precautions per OSHA requirements and

(2) do not enter sump until these precautions are strictly

adhered to.

• This pump has not been investigated for use in swimming

pool areas.

3. Tank should be vented in accordance with local plumbing codes

and should not be installed in locations classied as hazardous.

4. WARNING: Severe injury may result from accidental contact

with moving cutters. Keep clothing, hands and feet away from

cutters any time power is connected to the pump.

CALIFORNIA PROPOSITION 65 WARNING:

This product and related accessories contain

chemicals known to the State of California to cause cancer, birth

defects or other reproductive harm.

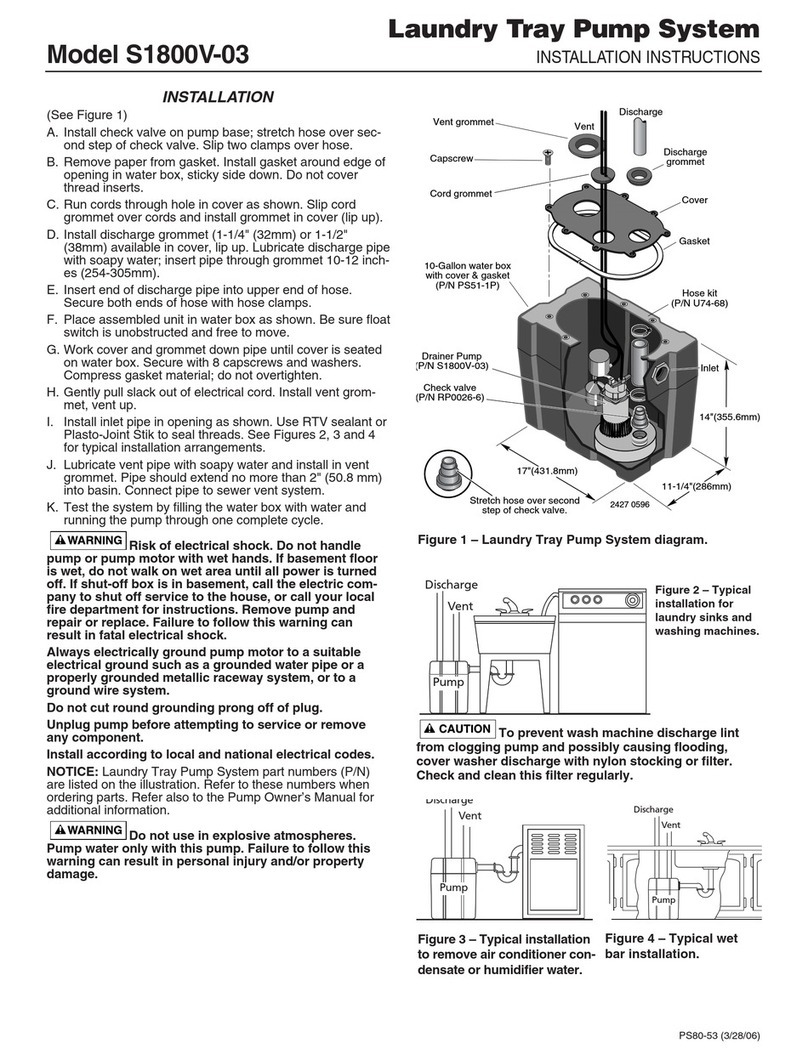

PUMP INSTALLATION

The cutter blades are on the suction side of the positive displacement

pump impeller and discharge directly into the inlet of the impeller.

The integral stainless steel pump motor shaft is sealed by a single

mechanical seal.

Two ball bearings are used to handle the loads in this design. The

upper bearing takes radial loads, while the larger lower bearing

handles both thrust and radial loads. Both bearings are permanently

lubricated by the dielectric oil in the motor housing. The motor is

xed within the motor housing and is completely submerged in the

dielectric oil for maximum heat transfer. The motor housing and seal

chamber are completely sealed with O-rings located at mating part

faces.

The power cord entry system is designed to give reliable sealing.

The rst seal is made by compression of a rubber gasket by the cord

grip, thereby expanding to ll the cord entry of the motor housing.

The cord grip forms a second seal around the molded cord end and

provides strain relief.

Application:

These pumps are designed for residential sewage discharge

applications with a pH ranging from 5 to 9, specic gravities from

0.9 to 1.1, viscosities ranging from 28 to 35 S.S.U. and temperatures

up to 140°F.

Pump Not Operating or in Storage:

Pumps with carbon ceramic seals must be manually rotated (6

revolutions) after setting nonoperational for 3 months or longer and

prior to electrical start-up.

Installing Pump in Sump:

Before installing pump in sump, lay it on its side and rotate grinder

shaft. Stator boot and rotor may be slightly stuck due to factory

test water so it must be broken loose by rotating shaft with a

screwdriver at the grinder end. The common shaft should turn with

a slight resistance. Slight lubrication by means of a small amount of

lubricating oil down the cavity inlet of the stator boot and rotating

shaft to prelube stator boot and rotor before start is recommended.

Do not connect the power until after this test. Clean all trash and

sticks from sump and connect pump to piping. A check valve must be

installed on each pump.

Location:

If pumps are installed in an existing basin or concrete sump, the

piping can either be connected permanently or rails and brackets can

be furnished for mounting to walls of basin. In either case, be sure

that the check valve is used and that the pumps are submerged in

a vertical position. The complete factory built packaged system is

recommended for the most satisfactory and economical installation.

Making Electrical Connections:

All electrical wiring must be in accordance with local code, and only

qualied electricians should make the installation. All wires should

be checked for shorts to ground with an ohmmeter or megger after

the connections are made. This is important, as one grounded wire

can cause considerable trouble.

PUMP OPERATIONS

To start the pump, perform the following steps

in order:

1. Grinder pump is single phase; no rotation check

is necessary.

2. Run water into sump until motor is covered.

3. Open gate valve in discharge line.

4. Turn pump on. If pump runs and sump liquid does not pump

down, stop pump and close discharge gate valve. Lift pump until

sealing ange is open to vent off trapped air. Lower pump, open

discharge valve, and start the pump again.

CAUTION: Positive displacement pump is designed to operate at

minimum 5 GPM capacity. Running pump at shut-off condition

or with gate valve closed can result in damage to the pumping

stator boot and rotor.

5. Level control should be set so that pump turns off when level is

about 2 inches above inlet of pump suction and turns on when

level is about 2 inches above motor.

6. If problems occur, check power source.

Make sure a separate supply line is available.

Verify voltage supply.

7. Check resistance of windings. If not within guidelines, return

pump to authorized factory service center.