Pentair LINCOLN POWER-MASTER III Owner's manual

This manual suits for next models

10

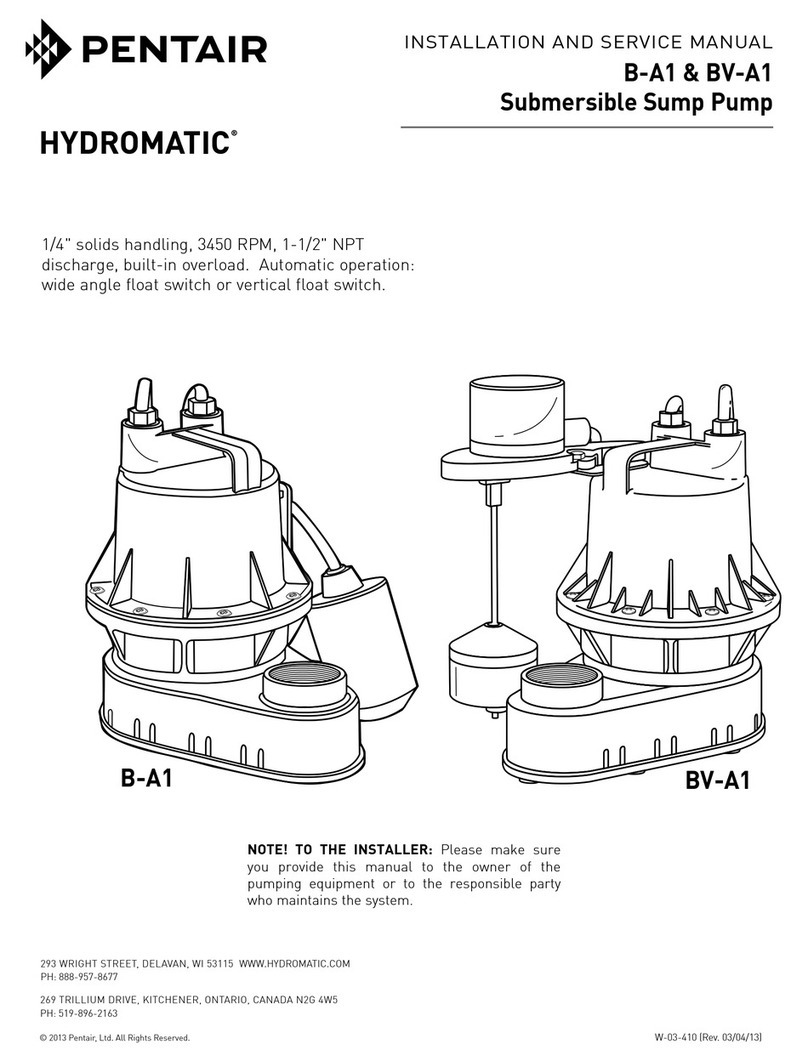

Other Pentair Water Pump manuals

Pentair

Pentair BERKELEY B4ZRKS User manual

Pentair

Pentair WCFIX 260V/3 User manual

Pentair

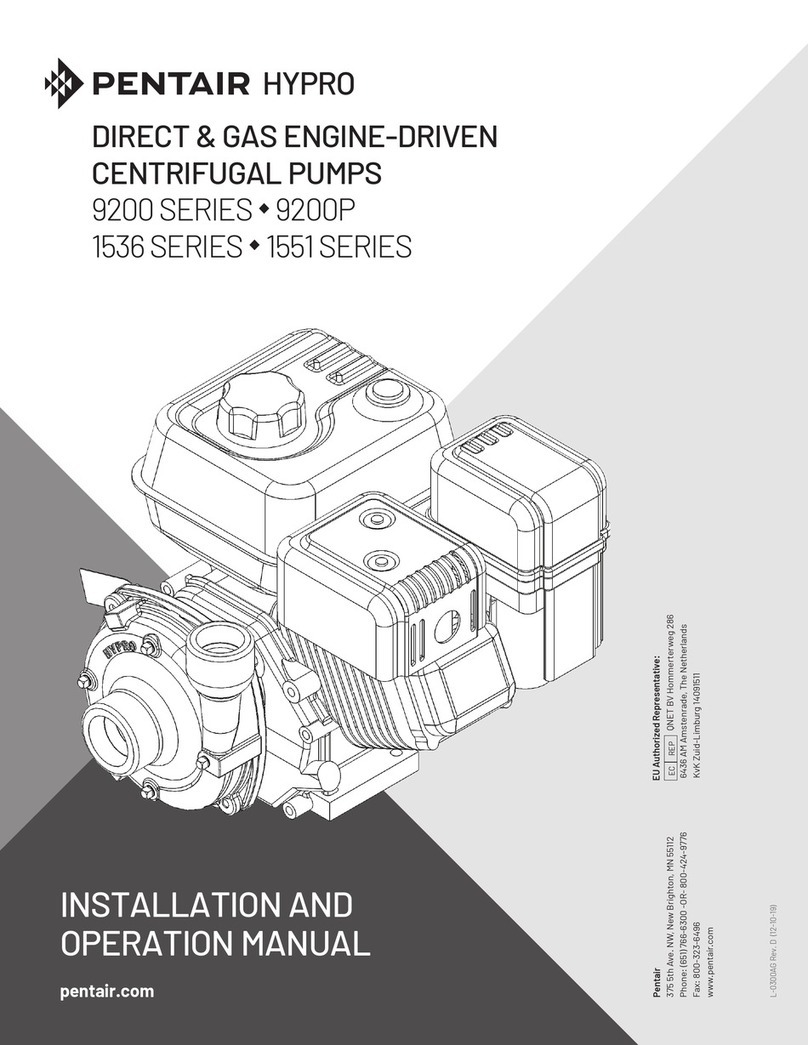

Pentair Hypro 9200 Series User manual

Pentair

Pentair MYERS 4VC User manual

Pentair

Pentair STA-RITE User manual

Pentair

Pentair Aurora 1060B Series Operating instructions

Pentair

Pentair HYPRO 9305C Series User manual

Pentair

Pentair MYERS WGL20 Manual

Pentair

Pentair IntelliFloXF User manual

Pentair

Pentair MYERS S33 Manual

Pentair

Pentair WhisperFloXF User manual

Pentair

Pentair Master Plumber 176958 User manual

Pentair

Pentair Myers WHR Series Manual

Pentair

Pentair AURORA 3310 Operating instructions

Pentair

Pentair JUNG PUMPEN K2 plus User manual

Pentair

Pentair AURORA 1070 Series Operating instructions

Pentair

Pentair Fairbanks nijhuis 5800 Installation and operating instructions

Pentair

Pentair PVM32 User manual

Pentair

Pentair SuperFlo VS User manual

Pentair

Pentair JUNG PUMPEN K2 plus User manual

Popular Water Pump manuals by other brands

Calpeda

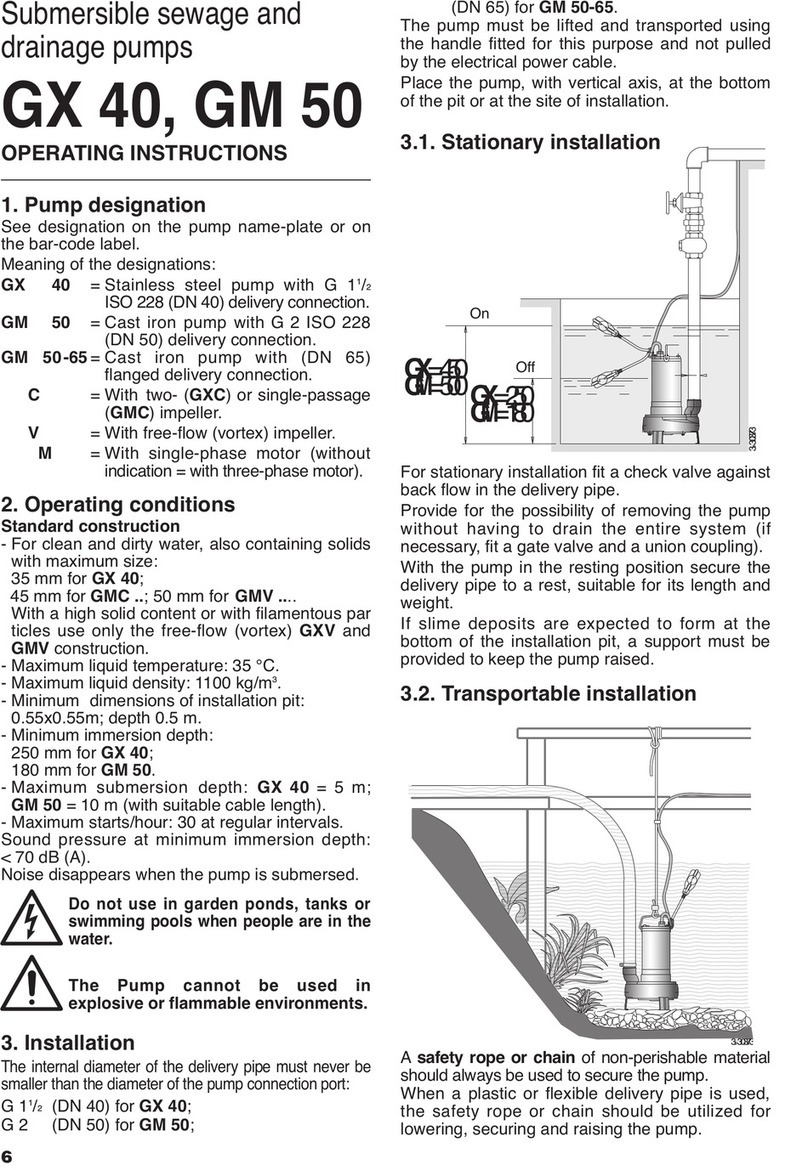

Calpeda GX-40 operating instructions

Garmin

Garmin Smartpump installation instructions

Blue-White industries

Blue-White industries ProSeries Chem-Pro C2F Series manual

Grundfos

Grundfos CRT Installation and operating instructions

OLIJU

OLIJU CMH Series Installation and operation instructions

Maruyama

Maruyama MP2500E2 instruction manual

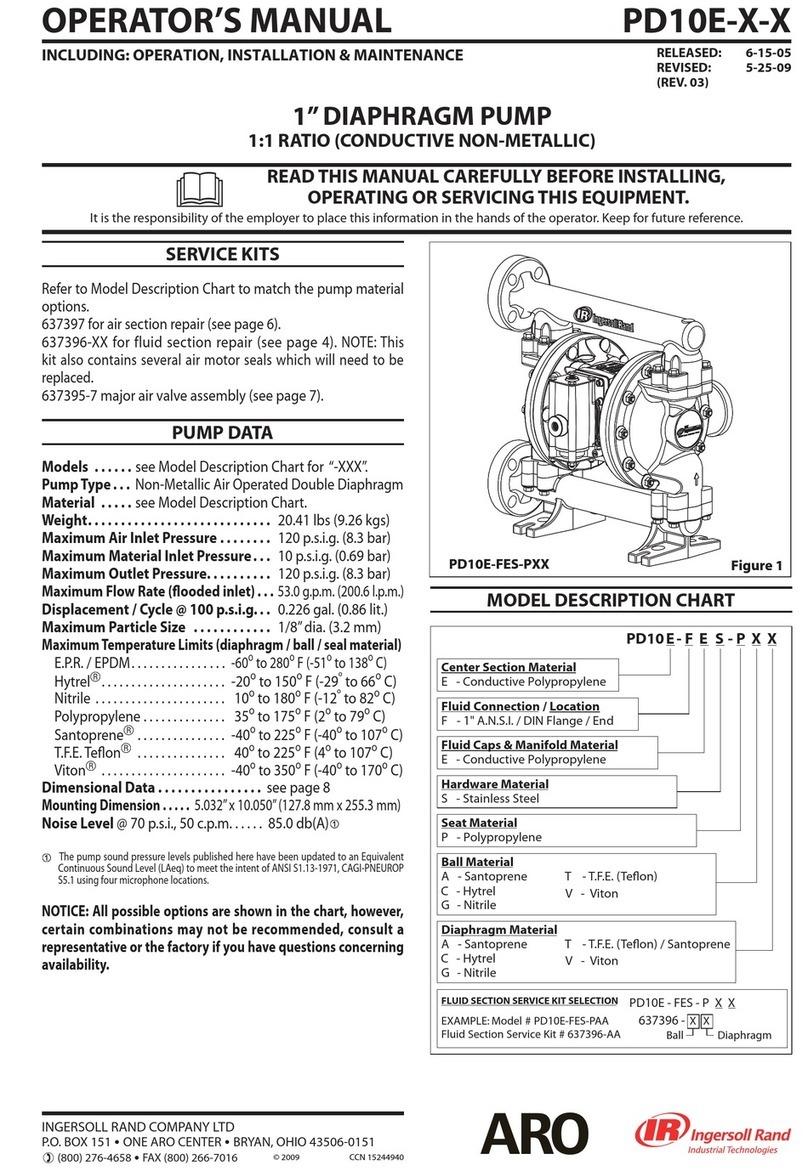

Ingersoll-Rand

Ingersoll-Rand PD10E-X-X user manual

Grundfos

Grundfos CRN 95-8 Installation and operating instructions

Grundfos

Grundfos AP80 Vortex Installation and operating instructions

Pfeiffer Vacuum

Pfeiffer Vacuum UNO 6 operating instructions

Varian

Varian SD-91 instruction manual

Grundfos

Grundfos Sololift2 CWC-3 Installation and operating instructions

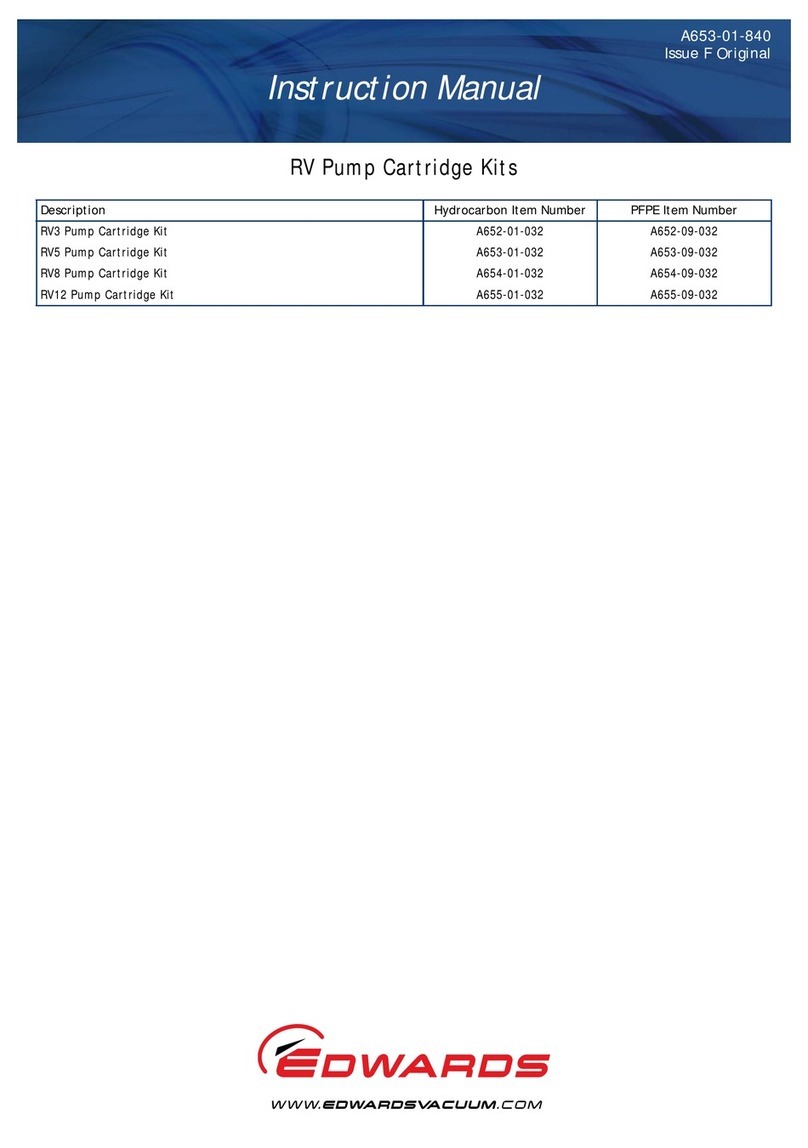

Edwards

Edwards RV Series instruction manual

Edwards

Edwards nXDS6i instruction manual

Gormann-Rupp Pumps

Gormann-Rupp Pumps AMT 25FP Series Specifications information and repair parts manual

JEC Pumps

JEC Pumps AccuLAB Series operating & maintenance manual

Sartorius

Sartorius 16615 operating instructions

Enerpac

Enerpac of 150 instruction sheet