7

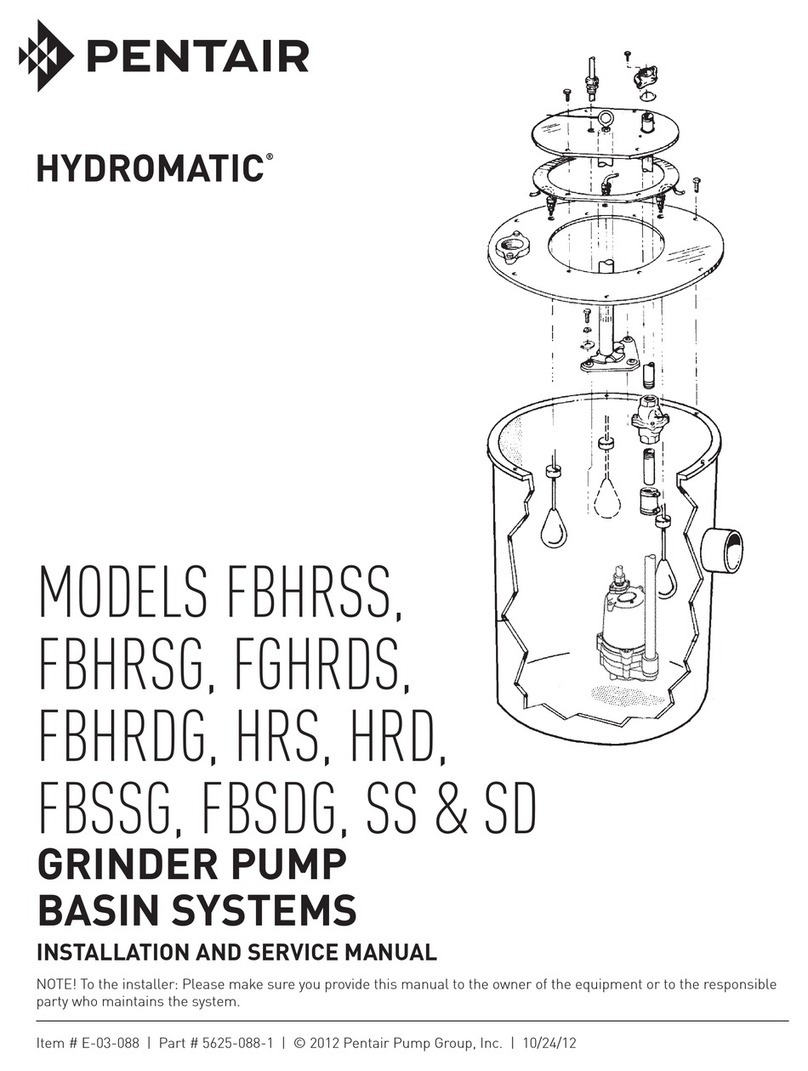

13. Reinstall the coupling (43) on the pump and motor

shaft. If the pump has a shaft pin, the pin axially

locates the pump shaft. If the pump does not have a

shaft pin, then set the coupling so that it grips equal

lengths of the pump and motor shaft.

14. Tighten the coupling’s socket head cap screws (73).

NOTICE: Torque settings are critical to prevent

coupling movement. If the coupling is not tightened

to the correct torque, it could slip on the shaft and

overheat and damage both the coupling and the

shaft. Refer to Table III, for torque specifications. Be

sure to tighten the two halves of the coupling evenly

(see Figure 8).

15. Remove the stack height adjustment tool and clip it

to one of the coupling guards.

16. Rotate the shaft to make sure that there is no

interference. After assembly there should be a small

gap between the shaft collar and the bracket. If

anything rubs, repeat steps 13, 14, and 15 to readjust

pump shaft height.

17. Reinstall the coupling guards.

NOTICE: The guards should be in place before the

unit is run.

18. Open the suction and discharge valves. Turn the

power back on.

Replacing Mechanical Seal

1. Follow Steps 1-7 under Motor Replacement and then

proceed with Step 2 below.

2. Loosen the three set screws in the shaft collar above

the mechanical seal and remove the shaft collar.

3. Remove the four retaining bolts (69) that hold down

the seal flange and seal.

4. Use a flat screwdriver to pry up the seal flange.

Remove the top portion of the seal.

5. Using the three round holes on the top of the shaft

sleeve, or notch in flange (see Figure 9), remove the

remaining portions of the seal.

6. Clean the seal seat area with a wetted cloth.

NOTICE: Be sure that you do not scratch, chip, or

scar the seal face. Be sure that the seal face is clean

before finishing assembly.

7. Wipe a small amount of water onto the O-Ring on

the inside of the new seal.

8. Slide the new seal assembly onto the shaft as a single

unit.

9. Install the four retaining bolts in the seal flange and

tighten them to 3.0 foot-lbs. (4.0 Nm).

10. Follow Steps 8 through 19 under Motor Replacement

to reinstall the motor.

Replacing Pump Stack

The reference numbers [shown as (11) or (88)] refer

to the exploded views, Figures 10-13. See the

appropriate exploded view for your model series.

1. Follow steps 1-7 under Motor Replacement, then

proceed with step 2 below.

2. Remove the motor bracket adapter plate (50), if your

pump has one.

3. Follow steps 2-5 under Mechanical Seal

Replacement and then proceed with Step 3 below.

4. Remove the staybolt nuts (77) and flatwashers (78)

from the staybolts (81). Use vicegrips, if necessary,

to prevent the staybolts from unscrewing out of the

pump base.

NOTICE: It is not necessary to remove the staybolts

when replacing the stack.

5. With the base firmly attached to a solid floor,

pull the motor stool (36) or motor stool/pump

head assembly (36/53 or 36/56) straight up off the

staybolts.

6. Make a note of the orientation of any tabs in the

top of the stack assembly, then remove the stack

assembly by pulling it straight up.

7. Install the new stack assembly, making sure that the

orientation of the tabs matches the orientation of the

tabs on the old stack assembly.

8. Replace the stack sleeve O-Ring (82) located in the

motor stool (36/53) or pump head (36/56). Make sure

that the new O-Ring is evenly seated in the O-Ring

groove in the motor stool or pump head.

9. Apply water to the stack sleeve O-Ring in the motor

stool/pump head (82) and to the top of the stack

sleeve (48).

Figure 8 - Make Sure that the coupling halves are evenly

tightened

Shaft Sleeve

Flange

Head

Figure 9