13800A794 06/19/17 2

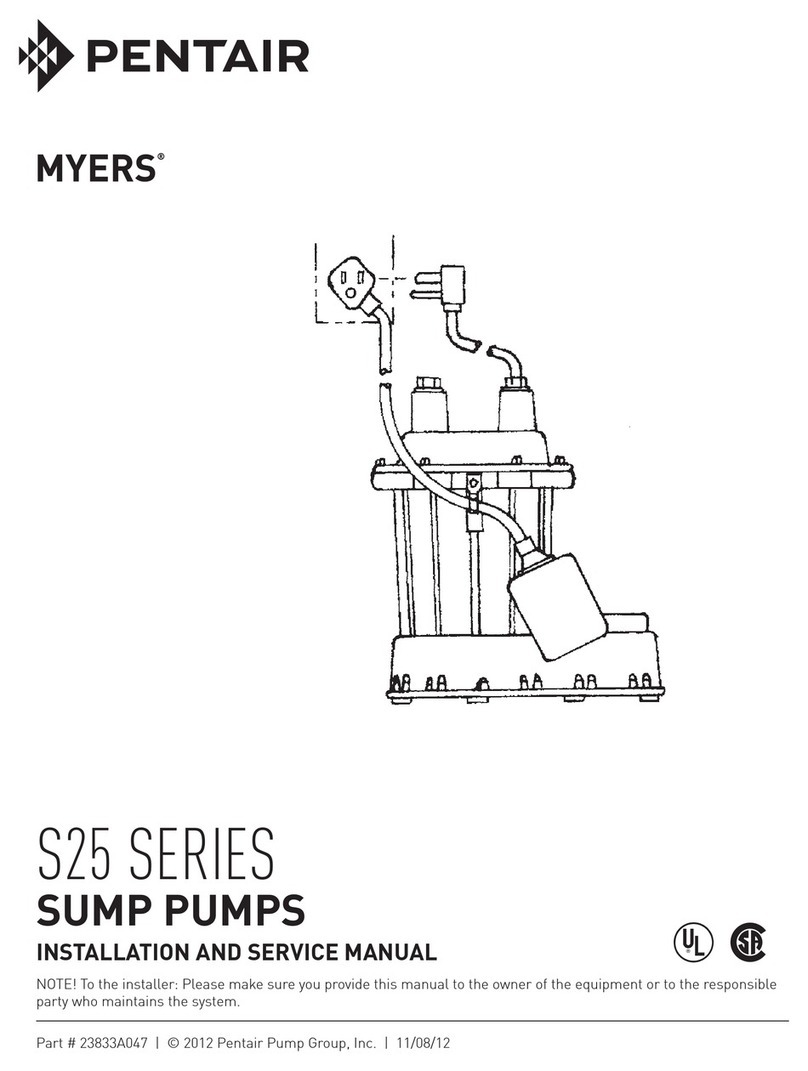

PACKAGE INCLUDES

1. Heavy fiberglass basin with steel sump cover

flanges (two removable cast iron pump covers/

flanges with duplex package). Sump cover has

3" NPT vent flange.

2. O-ring seal inlet flange for 4½" O.D. plastic pipe.

3. 1½" galvanized support pipe and conduit for

motor cords. (Two for duplex package.)

4. 1¼" galvanized discharge pipe, two pipes T.O.E.

(Two for duplex package.)

5. 1¼" slip coupling for discharge pipe. (Two for

duplex package.)

6. 3 float controls for mounting through cover.

(Four for duplex package.)

7. CV-125 angle check valve. (Two for

duplex package.)

CALIFORNIA PROPOSITION 65 WARNING:

AVERTISSEMENT!

This product and related

accessories contain chemicals known to the

State of California to cause cancer, birth

defects or other reproductive harm.

INSTALLATION INSTRUCTIONS

1. Remove pump cover from basin and take out all

parts. DO NOT REMOVE STEEL BASIN COVER.

2. Use template furnished with inlet flange and cut

hole in basin and drill for mounting bolts. Mount

inlet flange at height required for installation.

3. Basin is now ready to set in ground. Pour cement

around basin and up to basin flange to anchor basin

in the ground.

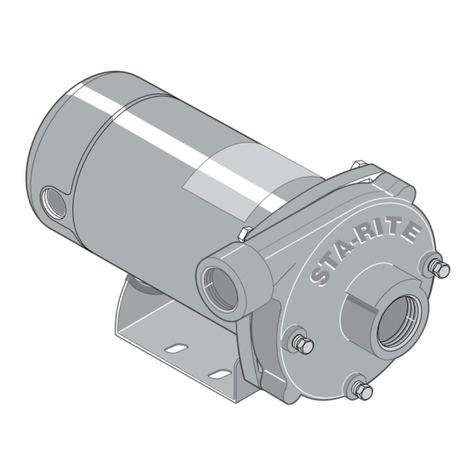

PREPARING PUMP FOR MOUNTING

IN BASIN

1. Screw one-half of 1¼" galvanized discharge pipe

into each pump. Use pipe dope or PTFE coating

tape on threads.

2. Pull two motor cords up through 1½" galvanized

support pipe and screw on to pump. Be sure pipe

coupling is on pipe.

3. Connect other half of 1¼" discharge pipe with 1¼"

slip coupling. Firmly tighten.

4. Place pump cover over pipes and tighten flange to

hold in place.

5. For simplex system: Plug extra hole with solid

rubber plug. Insert “OFF”, “ON” and “ALARM”

controls through rubber grommets. Adjust cords to

proper length. Insert floats through holes provided

in cover. Push rubber grommets into holes.

6. Place gasket on steel basin cover. Use permatex on

bottom side only to hold in place.

7. Lift pump and cover and lower into basin. Secure

with bolts.

8. Power cords are taken to control box for

connecting.

9. The motor cords can be installed in flexible

conduit if desired or can be left open and taped

together.

10.If pump is 3 phase, rotation should be checked

before pump is installed in basin. Lay pump on side

and connect to control box.

Turn hand-off-auto switch to “OFF” position,

then turn on circuit breaker. Quickly turn switch

to “HAND” then back to “OFF”. Note rotation of

grinder impeller. Impeller must rotate counter-

clockwise. If rotation is wrong interchange any two

motor leads at control box and re-check.

Anytime a new pump is installed, rotation

should be re-checked.

CAUTION – KEEP HANDS COMPLETELY

AWAY FROM GRINDER IMPELLER IN MAKING THIS

TEST.

STARTING PUMP

1. With circuit breaker at control box in

“OFF” position, turn hand-off-auto switch

to “AUTO” position (both breakers and both

switches for duplex system).

2. Turn circuit breaker to “ON” and run water into

basin (both breakers for duplex system).

3. When level tilts upper float, pump should start

and should run until lower float is deactivated,

causing pump to stop.

4. Repeat cycle several times. Yellow run light should

come on each time pump runs.

5. Turn hand-off-auto switch (both switches for

duplex system) to “OFF” and run water into basin

until alarm switch activates. Alarm will continue to

operate as long as the float control is in the

up position.

ALWAYS TURN THE ALARM SWITCH TO “ON”

POSITION AFTER TESTING.

6. Turn hand-off-auto switch to “AUTO” position and

pump is ready for automatic operation.

7. Replace blank sump cover for simplex system, or

solid rubber plugs in cover for duplex system, and

be sure discharge valve is wide open.