PFA SERIES INSTALLATION, OPERATION, MAINTENANCE 2

TABLE OF CONTENTS

Thank you for Purchasing a PFA Automatic Fryer from Perfect Fry!.....................................................................................3

Owner’s Responsibilities .......................................................................................................................................................4

Regulations & Recycling........................................................................................................................................................5

Safety First ............................................................................................................................................................................6

INSTALLATION

Electrical Power Supply (North American Models)................................................................................................................7

Electrical Power Supply (International Models).....................................................................................................................8

Accessory Outlets (North American Models).........................................................................................................................8

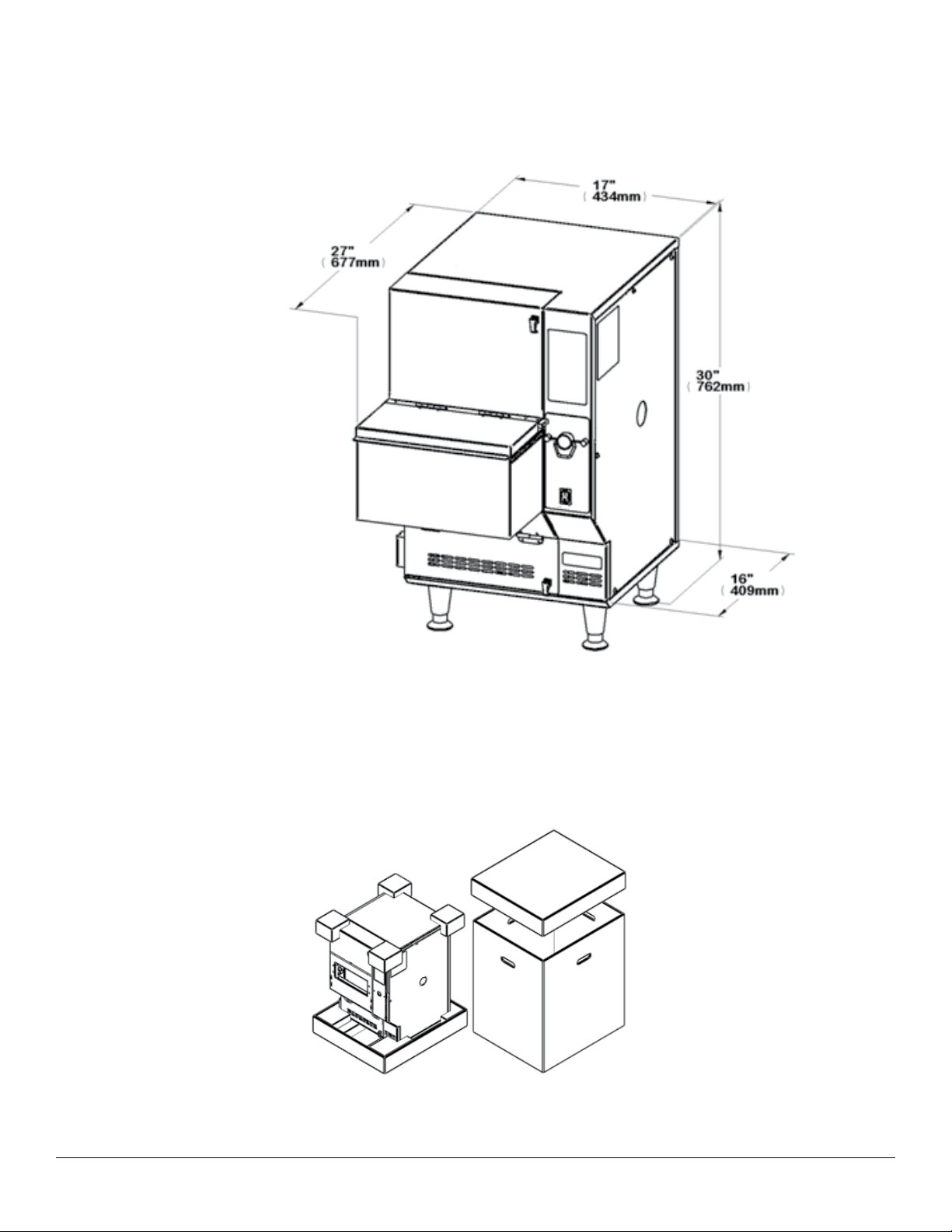

Prepare Countertop Area.......................................................................................................................................................9

Unpack ..................................................................................................................................................................................9

ASSEMBLY........................................................................................................................................13

COOKING ..........................................................................................................................................19

CLEANING

Daily Maintenance...............................................................................................................................................................20

Weekly Maintenance ...........................................................................................................................................................20

Periodic Maintenance..........................................................................................................................................................22

TIPS ON DEEP FRYING...................................................................................................................23

OIL FACTS.........................................................................................................................................24

OPERATING INSTRUCTIONS.........................................................................................................27

Manual Mode.......................................................................................................................................................................28

Preset Mode ........................................................................................................................................................................29

Open Drawer Lid - Paused Cook Cycle...............................................................................................................................34

Shutting Down .....................................................................................................................................................................35

USER DEFINED OPTIONS ..............................................................................................................36

CTSTM (Cook Time Sensitivity).............................................................................................................................................37

Option Changes...................................................................................................................................................................43

Customizing Presets............................................................................................................................................................44

Customizing Presets on the Front Label .............................................................................................................................45

HELP

System Error Conditions......................................................................................................................................................46

Troubleshooting Table .........................................................................................................................................................49

PFS AUTOMATIC EXTINGUISHER ................................................................................................51

DECLARATION OF CONFORMITY.................................................................................................53

ORIGINAL STANDARD EQUIPMENT LIMITED WARRANTY

US & Canada.......................................................................................................................................................................54

International Units................................................................................................................................................................56