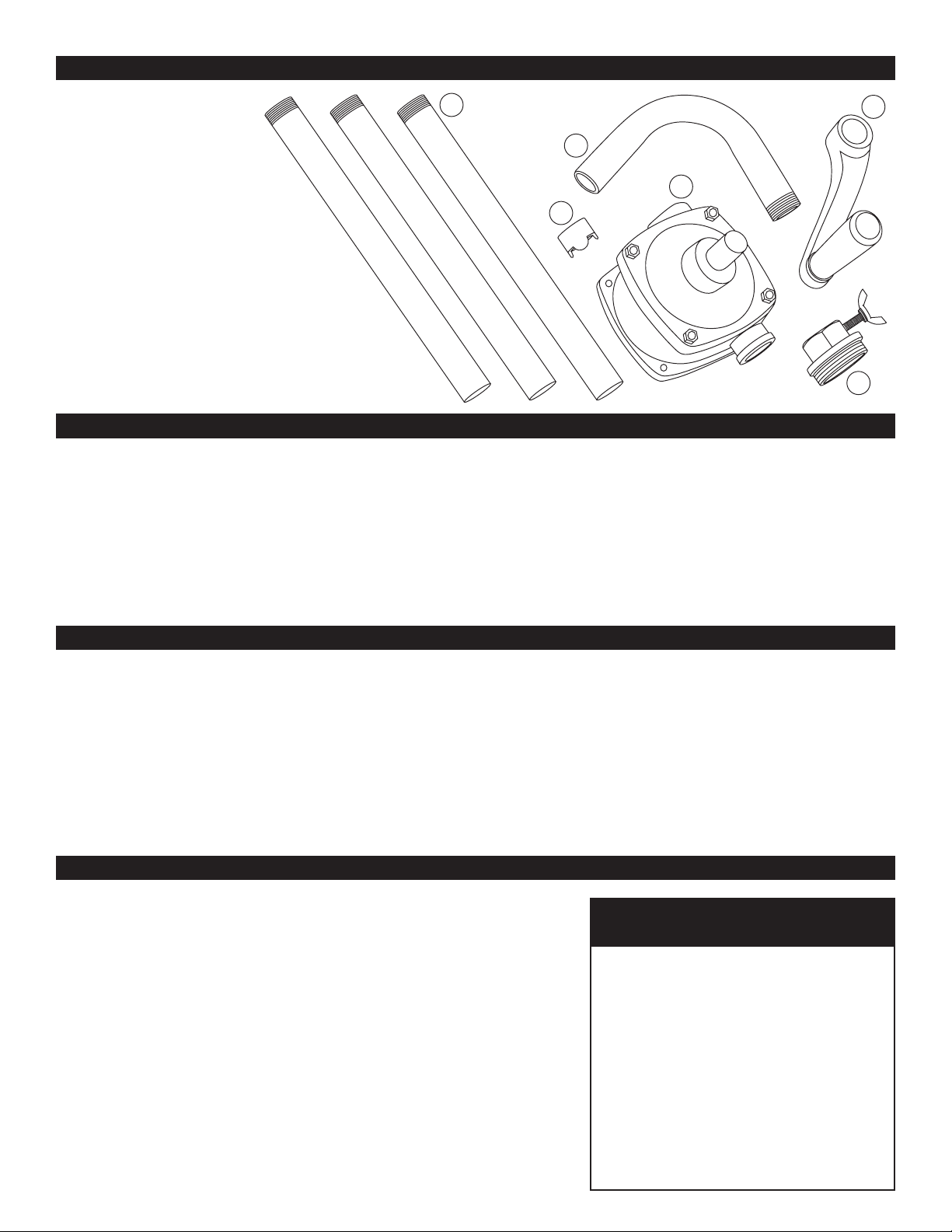

ASSEMBLY INSTRUCTIONS

Carefully unpack and spread

out all parts in a large

uncluttered area. Familiarize

yourself with all parts and

compare them to the drawing

to make sure none are

missing.

PARTS LIST

1

2

3

4

5

6

# Description Qty.

1 Handle .......................... 1

2 Pump............................ 1

3 Delivery Spout ............. 1

4 Suction Pipe................. 3

5 Bung Nut ...................... 1

6 Strainer......................... 1

1. Read and understand instruction prior to continuing.

2. Screw the suction pipe into the inlet port of the pump. Pay close attention to the directional arrows on the pump

body, as well as the inlet and outlet markings. They show the direction of the fluid flow. If you notice bubbles in

the barrel and you’re not getting delivery you have the pump assembled in reverse.

3. Slide the bung nut over this section of pipe. Use the wing nut to tighten it in place on the suction pipe. Assemble

the balance of the suction tubes together as needed for your application. Be sure the strainer is added to the

end. Use PTFE tape on all of the threads

4. Slide the handle onto the shaft on the pump body. Tighten together using the hex bolt.

5. Screw the delivery spout onto the threaded outlet on top of the pump body.

6. Lower the entire assembly into the bung opening adjust bung nut as needed and secure in place.

OPERATION INSTRUCTIONS

1.

Assemble the pump as described in the assembly instructions. Pay

close attention to the directional arrows on the pump body. This

shows the direction of the flow. If you notice bubbles in the barrel and

you’re not getting delivery you have the pump assembled in reverse.

2. To prime the pump, turn the discharge spout upwards and pour in a

few drop of oil.

3. A hose can be attached to the end of the deliver spout if desired.

4.

Put a container under the delivery spout or set the hose end in the container.

5. Completely submerge the lower half of the suction pipe into the fluid

in the barrel.

6. Pump the handle steadily to begin the fluid transfer.

7. Pump until the desired amount is in the container.

8. Always do a reverse rotation to clear out any undelivered fluid.

Please Note: Avoid running water or residue from the bottom of the barrel.

The intake tube can be raised to avoid any contaminated fluids.

1.

Before each use, inspect the general

condition of the pump. Be sure there

are no broken, bent, damaged, or

missing parts. Anything that might

affect the performance of this

product should be avoided.

2. Lubricant where needed such as on

the handle’s pivot parts.

3. Keep the suction and delivery ports

clean and free of dirt and debris.

4. After each use, wipe off the unit,

store in a clean dry place.

INSTRUCTIONS & PRECAUTIONS

- Designed to pump clean oil and other light petroleum product

- Do not use with flammable liquids such as gasoline, kerosene, acetone, thinners etc.

- Also do not use acids, alkaline solutions, or other corrosive liquids

- Do not use to pump water as this will rust the interior and shorten the units life.

- Not designed to pump used fluids such as motor oil.

- Barrel Pump and fluids should be keep away from all ignition sources and flammable material.

- Use only according to these instructions and its intended use.

- Always wear ANSI approved safety glasses or goggles when pump is in use.

SAFETY WARNING

Read all assembly instructions before beginning.