Replacement Parts – Narrow Door Back Bar Cabinets

5

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

Form No. Z2285

Rev. 01.04.09

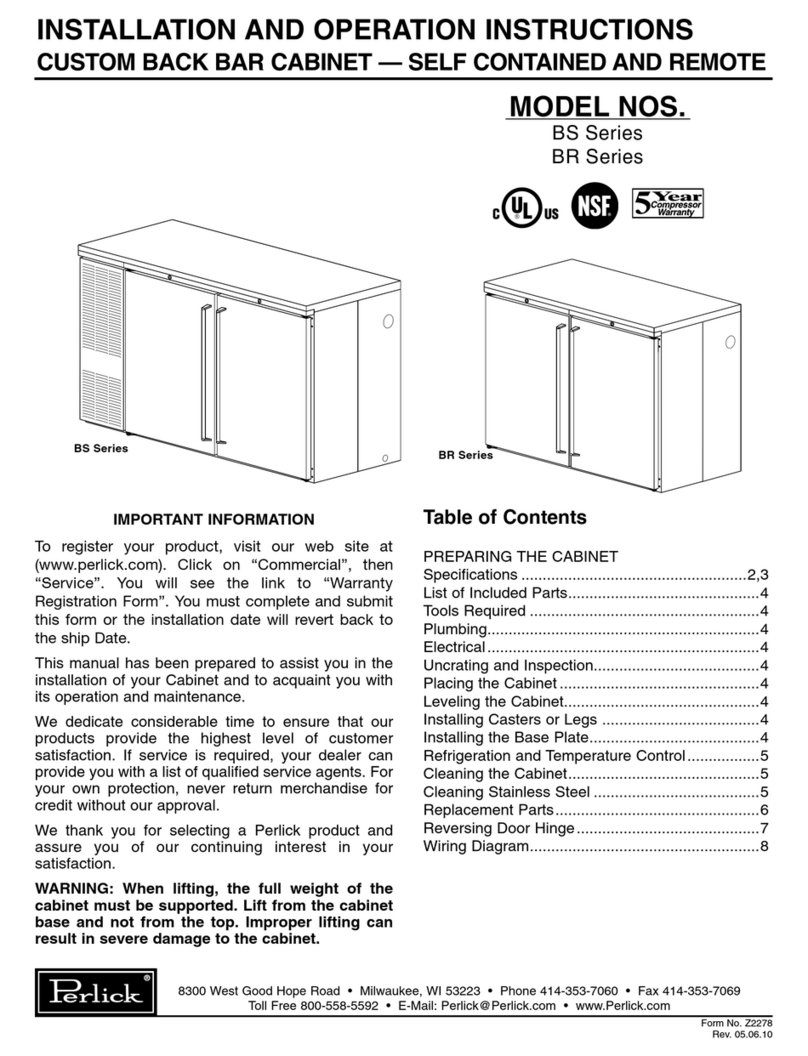

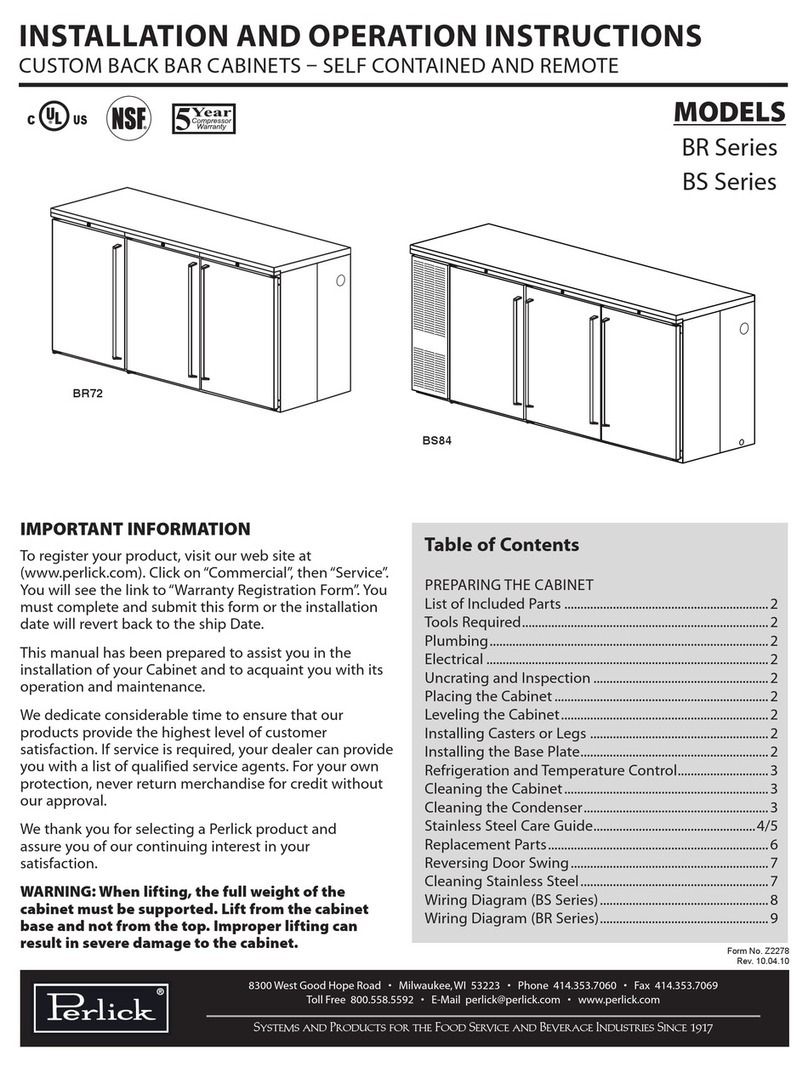

MODEL NOS. NS52 NS72

Condensing Units (BS Only)

Condensing unit 115 volt, 60 hz. C22647 C22646

Condensing unit 515301063 515301062

Compressor 513200314 513200003

Fan motor assembly 515315009 515315009

Condenser coil 15352019 15352019

Terminal board 519100088 519100088

Overload protector US-PB10HBX1 US-PB12HBX1

Relay US-PB10HBX1 US-PB12HBX1

Capacitor US-PB10HBX1 US-PB12HBX1

Evaproator Assembly

Self Contained (BS) complete 66308 65555-2

Evaporator coil (BS) &(BR) C17511-1EP C17511-2EP

Liquid & Suction line (BS) 65084 65085

Fan blade 57699 57699

Fan motor C15239A C15239A

Evaporator fan guard 65557 65557

Temperature control 61283 61283

Bulb clamp C6634 C6634

Wire harness, compressor bottom 65560 65560

Wire harness, evaporator 65561 65561

Wire harness, light jumper 65538 65539

Wire harness, mullion heater 65571 65572

Light bulb 63821 63821

Light bulb guard 65525 65525

Light socket 63484 63484

Light switch 65535 65535

Lock 63762 63762

Space, lock 63761-1 63761-1

Lock rail 65432-20SS or 65432-20 65432-20SS or 65432-20

Grille rail 65432-12SS or 65432-12 65432-12SS or 65432-12

Condenser pan 65565-1 65565-1

Condenser end panel 66215-1SS 66215-1SS

Grille, black 66210-12 66210-12

Grille, SS 66210-12SS 66210-12SS

Condenser housing back 65435-12SS 65435-12SS

Evaporator, liquid & suction line cover 65606L-1 or 65606R-1 65576-4L or 65576-4R

Evaporator pan 66311-1 65526-2

Door handle Several Options - Contact Factory

Door gasket 66237-5 66237-5

Cabinet hinge group left 66264L 66264L

Cabinet hinge group right 66264R 66264R

Hinge pin 63679-1 63679-1

End shelf kit - flat 66342-NE 66342-NE

Center shelf kit - flat — 66342-VM

Left or right shelf - flat 66355 66355

Center shelf - flat — 66356

End shelf kit - divided 66342-VE 66342-VE

Center shelf kit - divided — 66342-VM

Left or right shelf - divided 66398-1 66398-1

Center shelf - divided — 66399-1

Pilaster strip C19271-1 C19271-1

Shelf clip C15875 C15875

*Replacement door RD-NL2 RD-NL2

*Contact Perlick Milwaukee for complete door replacement. Cabinet serial no. required.