Sprayer Operation, Calibration 5

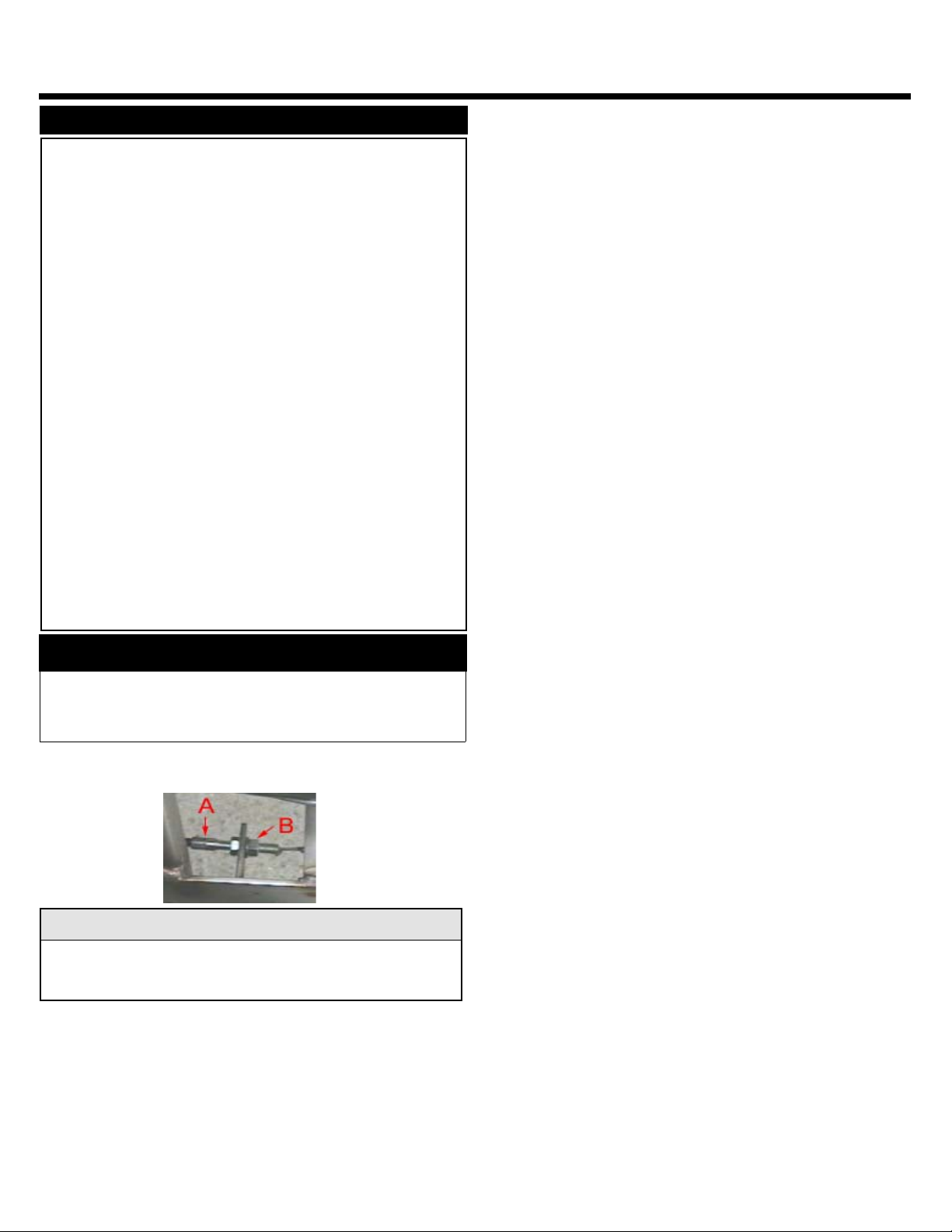

Adjusting the spray pattern

Broadcast Boom Nozzles

1) Rotate the 2 red turbo floodjet nozzles within the

red caps on the black nozzle bodies on the boom

until the spray pattern is generally forward with a

slight angle to the outside, so there is less overlap

in the center.

2) Rotate the entire nozzle body on the boom until

the spray comes out slightly less than parallel to

the ground and delivers the spray width desired.

(Up to a maximum of 9-10 feet).

Half Width Spray Nozzle (lower center

nozzle)

1) Rotate the blue extended range TJet nozzle within

the red cap until the spray pattern is level from

right to left.

2) Rotate the entire black nozzle body until the spray

pattern covers a distance that is about one half

the width of the broadcast spray boom.

Trim Nozzle (top center)

1) Rotate the green TJet nozzle within the red cap

until the spray pattern is level from right to left.

2) Rotate the entire nozzle body until the spray

pattern covers a distance of about the width of the

front of the machine.

Wand

1) Rotate the Tjet nozzle until the spray comes out at

an angle that is comfortable.

•Leaks may create a spray that can hurt you or the

environment. Use water to test the system for

leaks before adding chemicals.. Repair any leaks

immediately.

•Exposure to chemicals can cause serious bodily

injury or death. Always read and follow chemical

label directions and wear the safety equipment

mandated on the label.

•The spray may be difficult to see and be blown off

target by the wind. It is the operator’s

responsibility to apply chemicals in a safe manor.

WARNING!

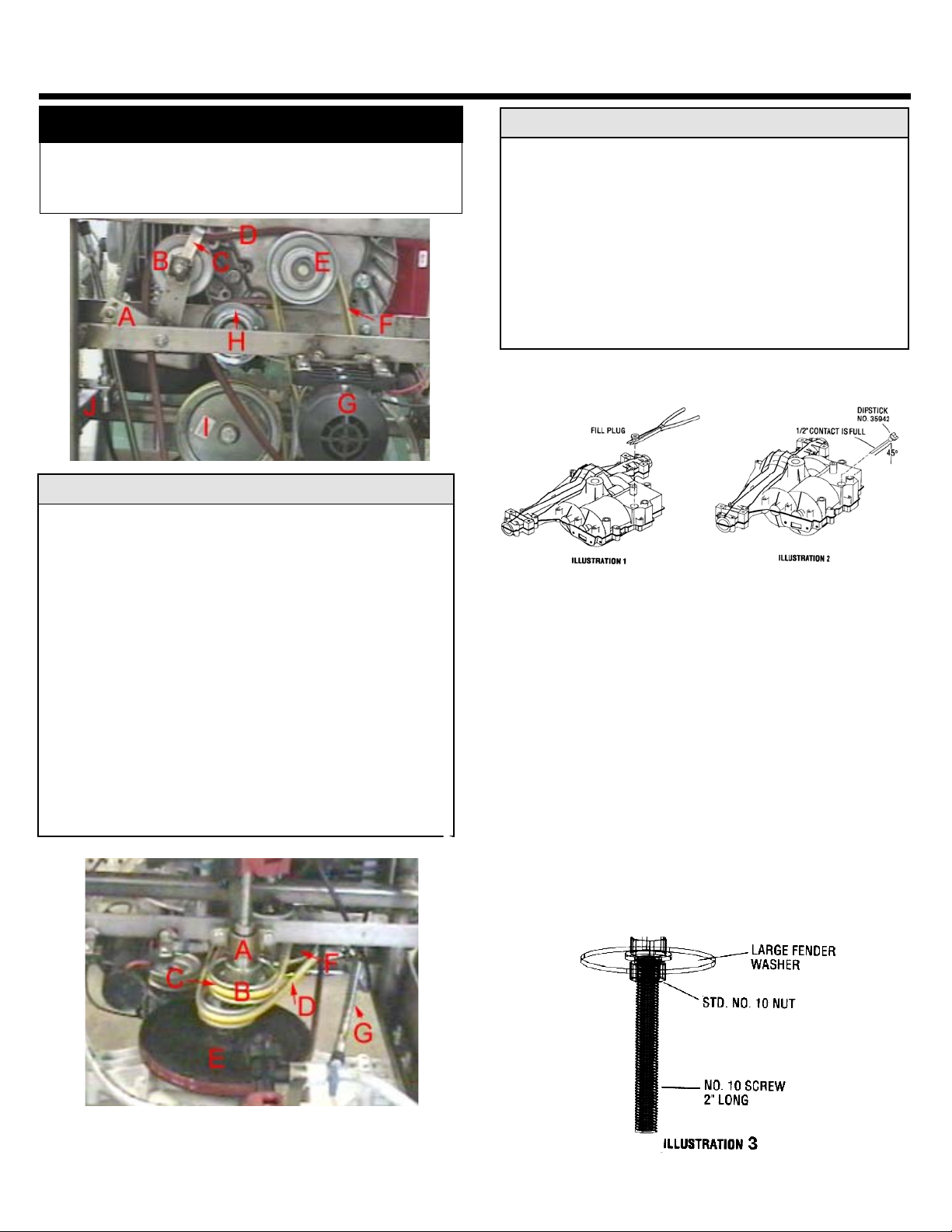

Suggested Method of Spraying

& Spreading

Use a double overlap spread. Turn so that on the

next pass the fertilizer reaches approximately back

to the center of your last wheel marks.

*Refer to pages 6 and 7, for instructions

*Set the spread rate dial so that you apply 1/2 rate

with each pass.

*Follow the Accuway instructions to center or

equalize the spread pattern, and then:

1) Mark off a test course and fill tanks with water.

2) Measure the area. Ex:100’x100’=10,000 sq ft

3) Turn on your spray boom and adjust your spray

pattern to the desired width of spray.

4) Fill the tanks with water to a marked line (mark

both tanks)

5) Spray the test course at your normal speed and

with your normal overlap (determined by your

spreader settings).

6) Measure the ounces of water necessary to

refill the tanks to the marks (allow adequate

time for the tank level to equalize).

7) Divide the amount of water used by the number of

1,000 sq.ft. incriments in your test course inStep 2.

This equals your spray rate in ounces per 1000

sq ft. Locate that number in the left column of

the MIX CHART.

8) Repeat the test a number of times to insure

accuracy.

9) From your product label, find the recommended

rate of chemical to apply per 1000 sq ft. Locate

that number in the top line of the MIX CHART,

10) Read across from your spray rate number in

the left column until it intersects with your

chemical per 1000 sq ft column. That number

is the amount of chemical needed to mix 1 gallon

of spray solution.

EXAMPLE: Your calibrated spray rate is 16 oz. per

1,000 sq.ft. and your product label requires 1.5 oz. of

chemical per 1,000 sq.ft. You would need 12 oz.of

chemical to mix 1 gallon of solution.