CONTENTS

1Introduction..................................................................4

2Safe and Correct Use..................................................5

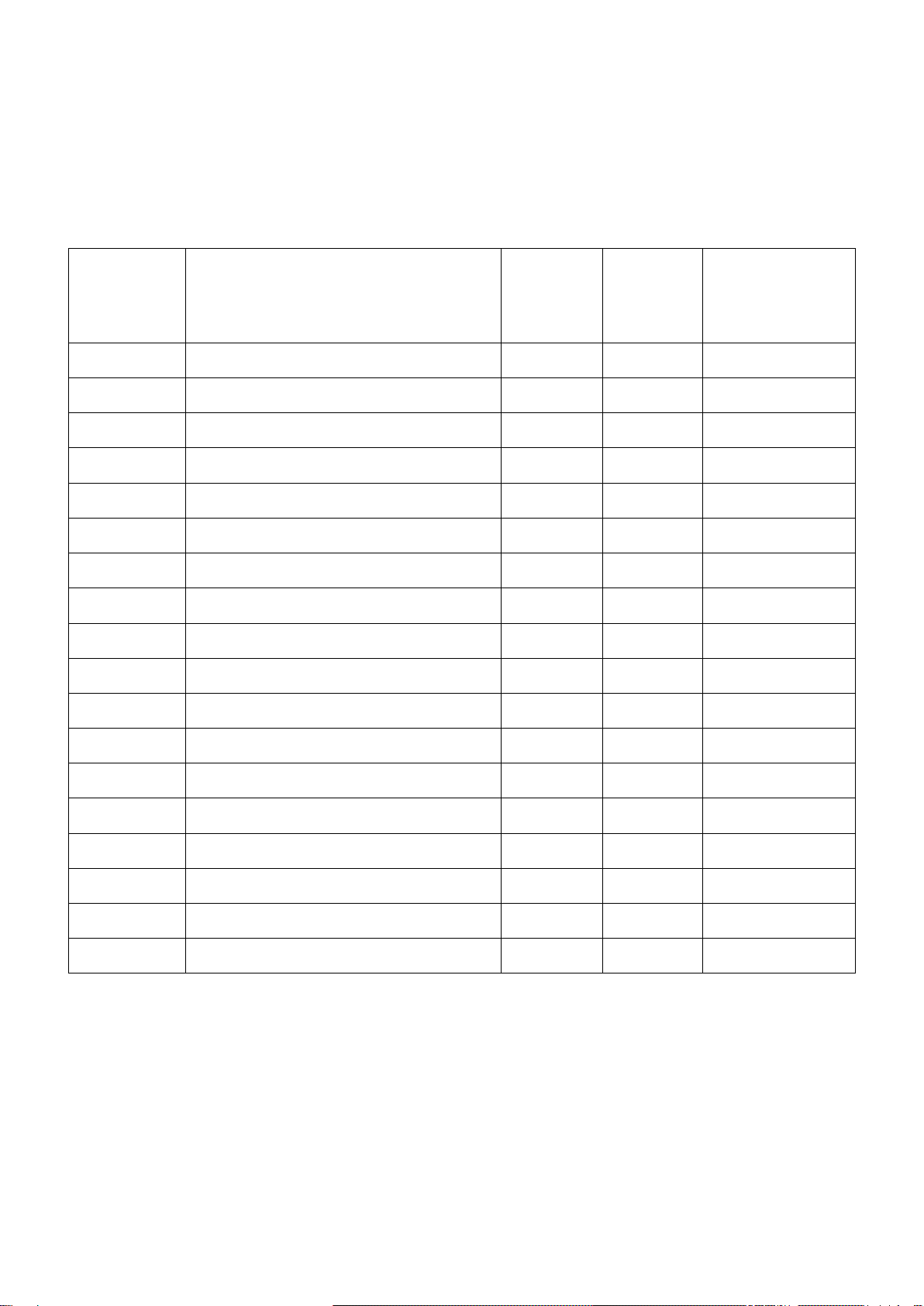

3Technical Specification................................................7

3.1 Physical Data for the Portable Sleeper Squarer

Main Components...........................................................7

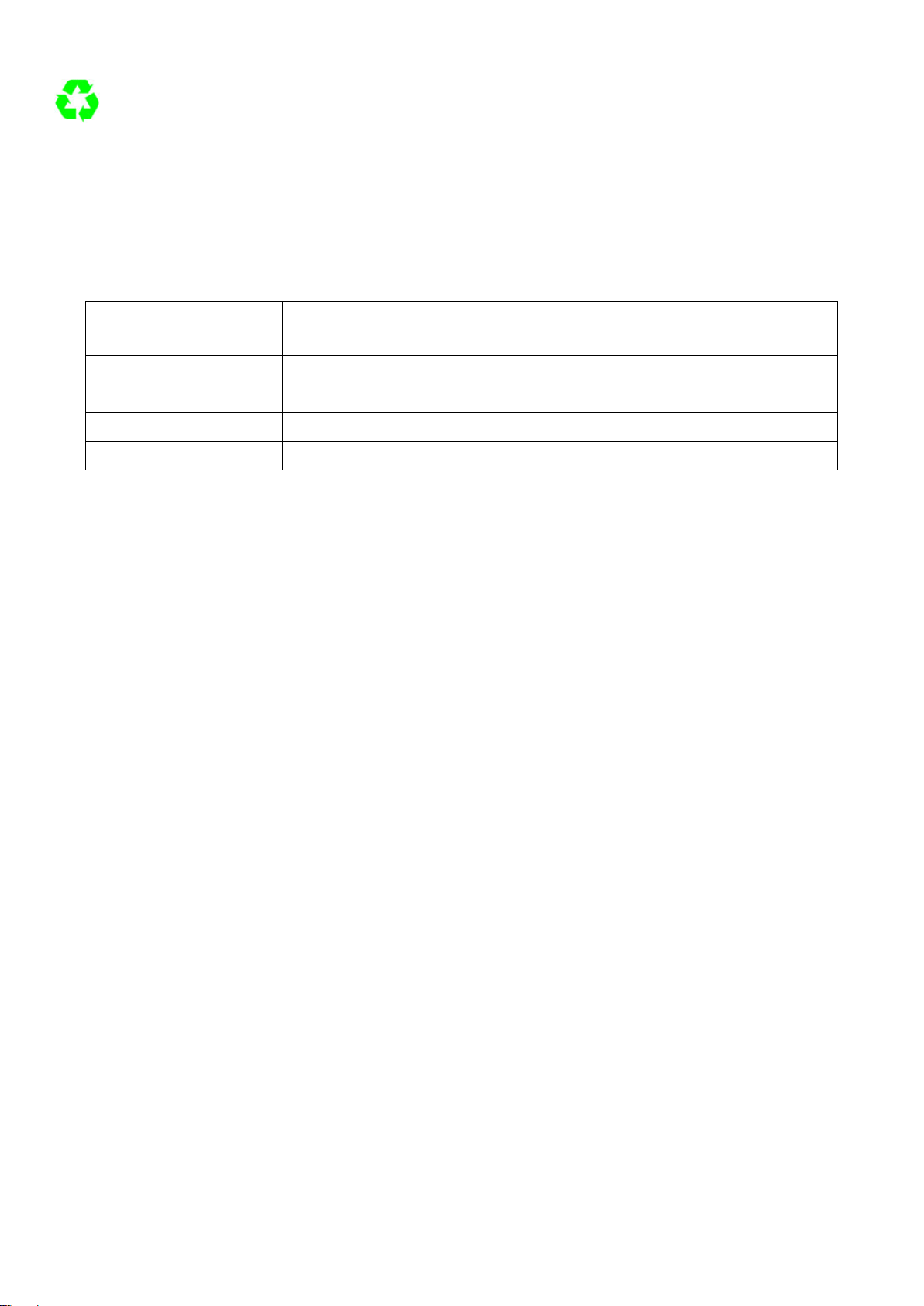

3.2 Oil Specification.....................................................7

3.3 Fuel Specification..................................................7

3.4 Operating Pressure ...............................................7

3.5 Operating Performance .........................................7

3.6 Power Pack Engine Emissions..............................8

3.7 Power Pack Engine Noise Emissions....................8

3.8 HAV.......................................................................8

3.9 Product Compliance ..............................................8

4General Layout..........................................................10

5Operating Instructions................................................11

5.1 Pre-use Checks...................................................11

5.2 Assembly.............................................................12

5.3 Starting the Engine..............................................13

5.4 Stopping the Engine ............................................13

5.5 Operating Duties..................................................14

5.6 Operating Procedure. ..........................................15

6Maintenance and Test...............................................16

6.1 Prior to despatch to site.......................................16

6.2 Weekly Maintenance/Safety Checks....................17

6.3 Annual/every 250 hours of running (which ever

occurs first)...................................................................17

7Training .....................................................................18

8Ordering ....................................................................19

9Hydraulic Circuit ........................................................20

10 ISO37 Oil Material Safety Data Sheet.....................22

11 Honda Engine Owners Manual...............................26

Please note

Whilst Permaquip Limited has taken every care in preparing this User Guide it is

intended as a technical guideline only. Save to the extent that there are statutory

rights to the contrary, Permaquip accepts no liability in relation to any use or

reliance made of any information in this User Guide.

All information, illustrations and specifications in this User Guide are based on the

latest information available at the time of publication. The right is reserved to make

changes at any time without notice.

Equipment operators and installers shall be responsible for ensuring that a safe

working environment and safe systems of work are in place and in certain

circumstances advice and permission from the controlling authority must be sought

before any operation, installation or surveying work is carried out.

Permaquip™ is a trademark of Permaquip Ltd.