Thetorchboxexhaustmustbeinstalled,buttheRFgenerator

exhaustisoptional(seenoteinTable7*).

TheRFgeneratorexhaustventisusedfortheblowerthat

cools the system power supplies and ICP generator.

Werecommendusingtwo100-mm(4in.)exhausthoses

(forboththetorchboxexhaustventandRFgenerator

exhaustvent).TheNexION300ICP-MSissuppliedwith6m

(22ft.)of100-mm(4in.)flexibletubing.Thistubingpermits

the movement of the instrument without disconnecting the

ventsfromthelaboratorysystem.SeeTables6and7for

vent specifications.

Inoperation,theroughingpumpproduces1200-1500W

(4100-5100BTU/hr)ofheat.Theheatfromtheroughing

pump is released into the laboratory. Proper ventilation is

required to remove this heat from the room or any enclosure

in which the pump is situated. There must be a minimum of

15cm(6in.)clearancebetweentherearofthepumpand

anyverticalsurfaceaswellasaminimumof35cm(14in.)

clearance in the front. It should be located away from other

heat generating sources such as the liquid cooling system.

TheambientairtemperaturemustNOTexceed40°Catthe

roughing pump control electronics.

Theheatfromtheliquidcoolingsystem(heatexchangeror

refrigeratedchiller)isalsoreleasedintothelaboratoryduring

operation. The heat exchanger will produce a maximum of

2000W(6825BTU/hr)ofheat.Therefrigeratedchillerwill

produceamaximumof3000W(10,000BTU/hr)ofheat.

Proper ventilation is required to remove this heat from the

room or any enclosure in which the liquid cooling system

is situated. Adequate clearance should be allowed on the

front, sides, and rear of the unit for access to connections

and components. The front and rear vents of the unit must

beaminimumof61cm(2ft.)awayfromwallsorvertical

surfaces so air flow is not restricted. It should be installed at

7

least1.4meters(4ft.)awayfromanyheat-generating

sources such as the roughing pump or other instruments.

Proper ventilation is critical for the heat exchanger – its

ambient air temperature must never exceed 30 ˚C.

Venting System Recommendations

Theexhaustflowrateattheinstrument(theabilitytovent

thesystem)isdependentoncustomer-providedblower,the

duct length, material and the number of elbows or bends

used. If an excessively long duct system or a system with

many bends is used, a stronger blower may be necessary to

provide sufficient exhaust volume at the instrument. Smooth

stainless steel tubing should be used instead of flexible stain-

less steel tubing, where flexibility is not required, to reduce

system friction loss or “drag.” A length of smooth stainless

steelductinghas20-30%lessfrictionlossthanacomparable

lengthofflexibleducting.Whensmoothstainlesssteel

tubing is used, elbows must be used to turn corners. These

elbowsshouldturnatnomorethan45degreesbetween

straight sections to reduce friction losses, and the number

of elbows should be minimized.

Additional recommendations on the venting system include:

• Theductcasingandventingsystemshouldbemadeof

materialssuitablefortemperaturesashighas70˚Cand

be installed to meet local building code requirements.

• Locatetheblowerasclosetothedischargeoutletaspossible.

All joints on the discharge side should be airtight, especially if

toxic vapors are being carried.

• Equiptheoutletendofthesystemwithabackdraft

damper and take the necessary precautions to keep the

exhaust outlet away from open windows or inlet vents

and to extend it above the roof of the building for proper

dispersal of the exhaust.

• Equiptheexhaustendofthesystemwithanexhaust

stack to improve the overall efficiency of the system.

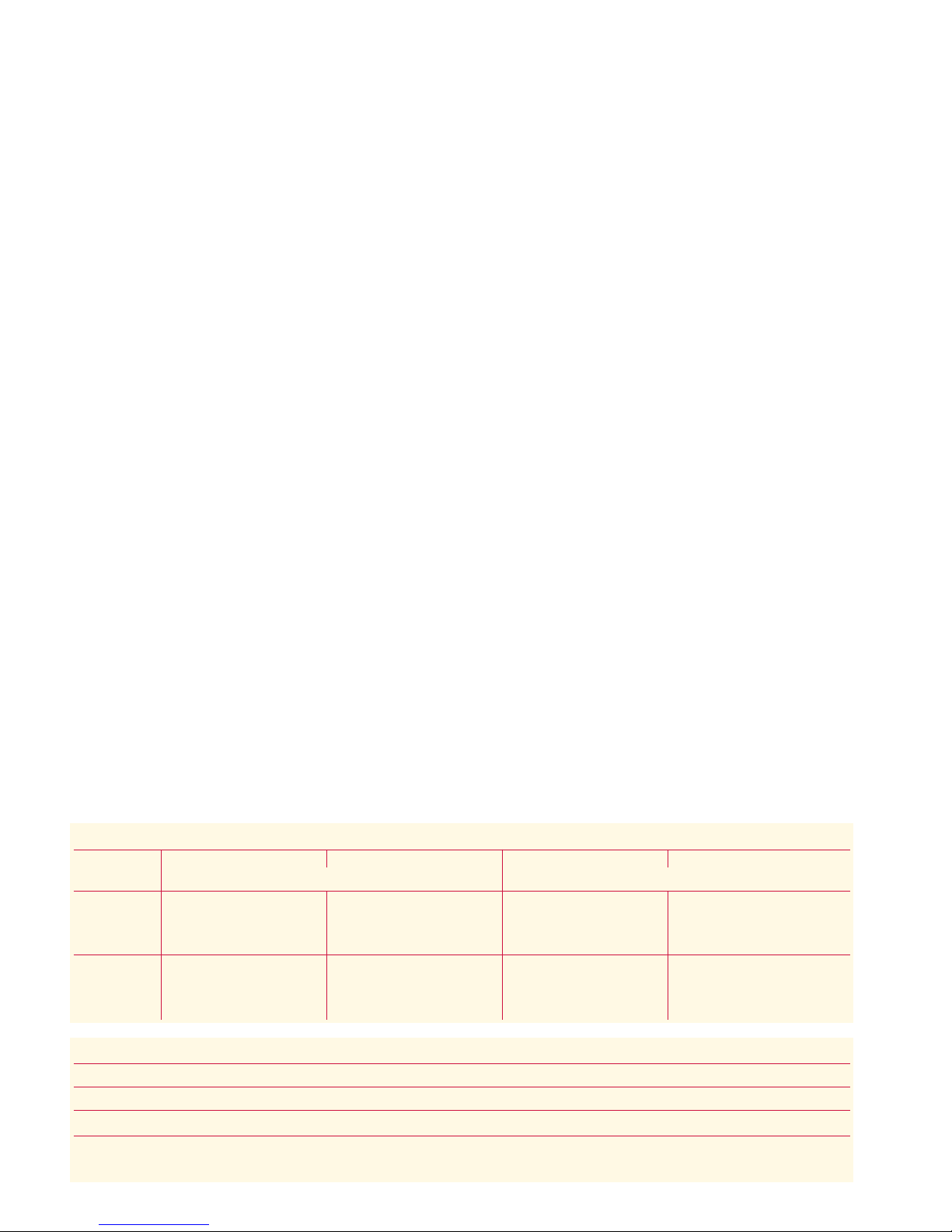

Table 7. Hose Diameter and Venting Capabilities.*

Hose Hose Diameter Heat Vented Outside Lab Watts (BTU/hr)

TorchBoxExhaust 100mm(4in.) 800(2720)

RFGeneratorExhaust 100mm(4in.) 1500(5100)

*IfonlytheTorchBoxexhausthoseisused,approximately1500W(5100BTU/hr)ofheatfromtheRFgeneratorexhaustisventedintothelab.

Anindependentroomairconditioner[3000W(10000BTU/hr)]isrecommendedtoremovethisadditionalheat.

Table 6. Instrument Exhaust Ventilation Requirements.

Required airflow Required air velocity Reference airflow Reference air velocity

measured with hose connected to NexION measured with hose disconnected from NexION

TorchBox

ExhaustPort 73–100ft3/min@0.5"H2O 836–1145ft/min@0.5"H2O 110–150cfm@0"H2O 1260–1719ft/min@0"H2O

(35–47L/sec@125Pa) (4.3–5.8m/sec@125Pa) (52–71L/sec@0Pa) (6.4–8.7m/sec@0Pa)

RFGenerator

ExhaustPort 150–160ft3/min@0"H2O 1719–1833ft/min@0"H2O 150–160ft3/min@0"H2O 1719–1833ft/min@0"H2O

(71–76L/sec@0Pa) (8.7–9.3m/sec@0Pa) (71–76L/sec@0Pa) (8.7–9.3m/sec@0Pa)