Table of contents

1 Overview.............................................................................. 7

2 Safety................................................................................. 11

2.1 Symbols in this manual............................................... 11

2.2 Intended use............................................................... 13

2.3 Safety signs................................................................ 14

2.4 Residual risks............................................................. 15

2.4.1 Basic dangers at the workplace............................... 15

2.4.2 Mechanical hazards................................................. 16

2.4.3 Thermal dangers...................................................... 16

2.4.4 Hazards due to hazardous substances and oper-

ating materials......................................................... 17

2.5 Behaviour in the event of an emergency.................... 18

2.6 Responsibility of the operating company.................... 18

2.7 Personnel requirements.............................................. 20

2.8 Personal protective equipment................................... 22

2.9 Spare parts................................................................. 23

2.10 Environmental protection.......................................... 24

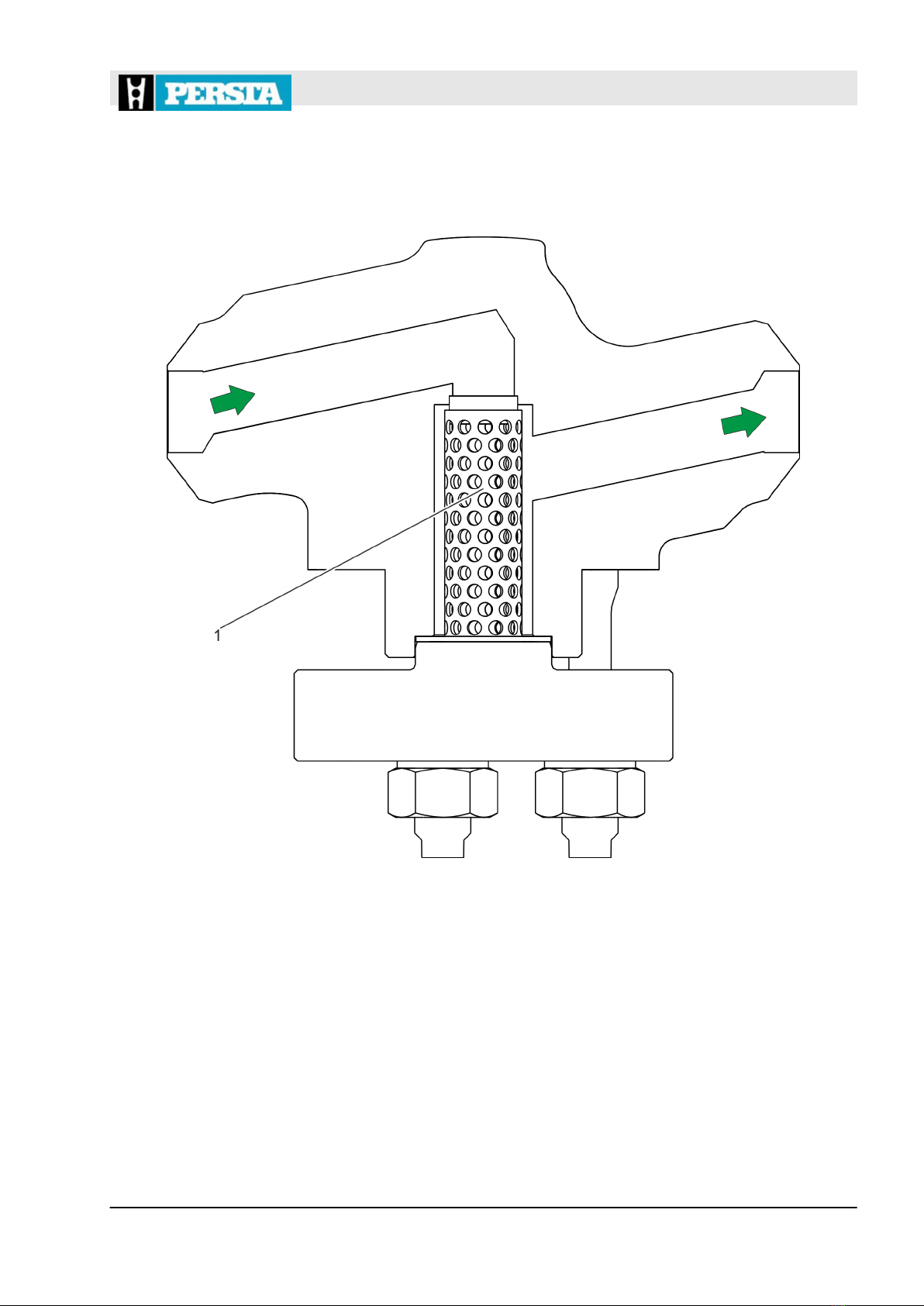

3 Functional description..................................................... 25

3.1 Mode of operation of the high pressure strainer......... 25

3.2 External seals............................................................. 26

3.2.1 High pressure strainer 990 ST................................. 26

3.2.2 High pressure strainer 990 SF................................. 27

3.3 Screen cylinder........................................................... 28

3.3.1 High pressure strainer 990 ST................................. 28

3.3.2 High pressure strainer 990 SF................................. 28

3.4 Connections................................................................ 29

4 Transport and storage...................................................... 31

4.1 Safety instructions for transport and storage.............. 31

4.2 Transport of packages................................................ 32

4.3 Storage of the valve.................................................... 32

4.4 Storage of spare parts................................................ 33

5 Installation......................................................................... 35

5.1 Safety notices for installation...................................... 35

5.2 Before the installation................................................. 36

5.3 Installing the valve...................................................... 36

5.4 After the installation.................................................... 37

5.4.1 Pickling the valve..................................................... 38

5.4.2 Painting the valve.................................................... 38

5.4.3 Executing the system pressure test and leak test... 38

5.4.4 Applying thermal insulation...................................... 39

6 Commissioning................................................................. 41

6.1 Safety notices for commissioning............................... 41

Table of contents

20.05.2021 High pressure strainer 990 ST/990 SF 5