Table of Contents

Contents ..................................................................................Page

13 Adjustment ....................................................................................................................... 5

13.01 Tools, gauges and other accessories .................................................................................... 5

13.02 Abbreviations ......................................................................................................................... 5

13.03 Explanation of symbols.......................................................................................................... 5

13.04 Adjusting basic machine ........................................................................................................ 6

13.04.01 Needle position to needle hole .............................................................................................. 6

13.04.02 Needle height (pre-calibrating) ............................................................................................... 7

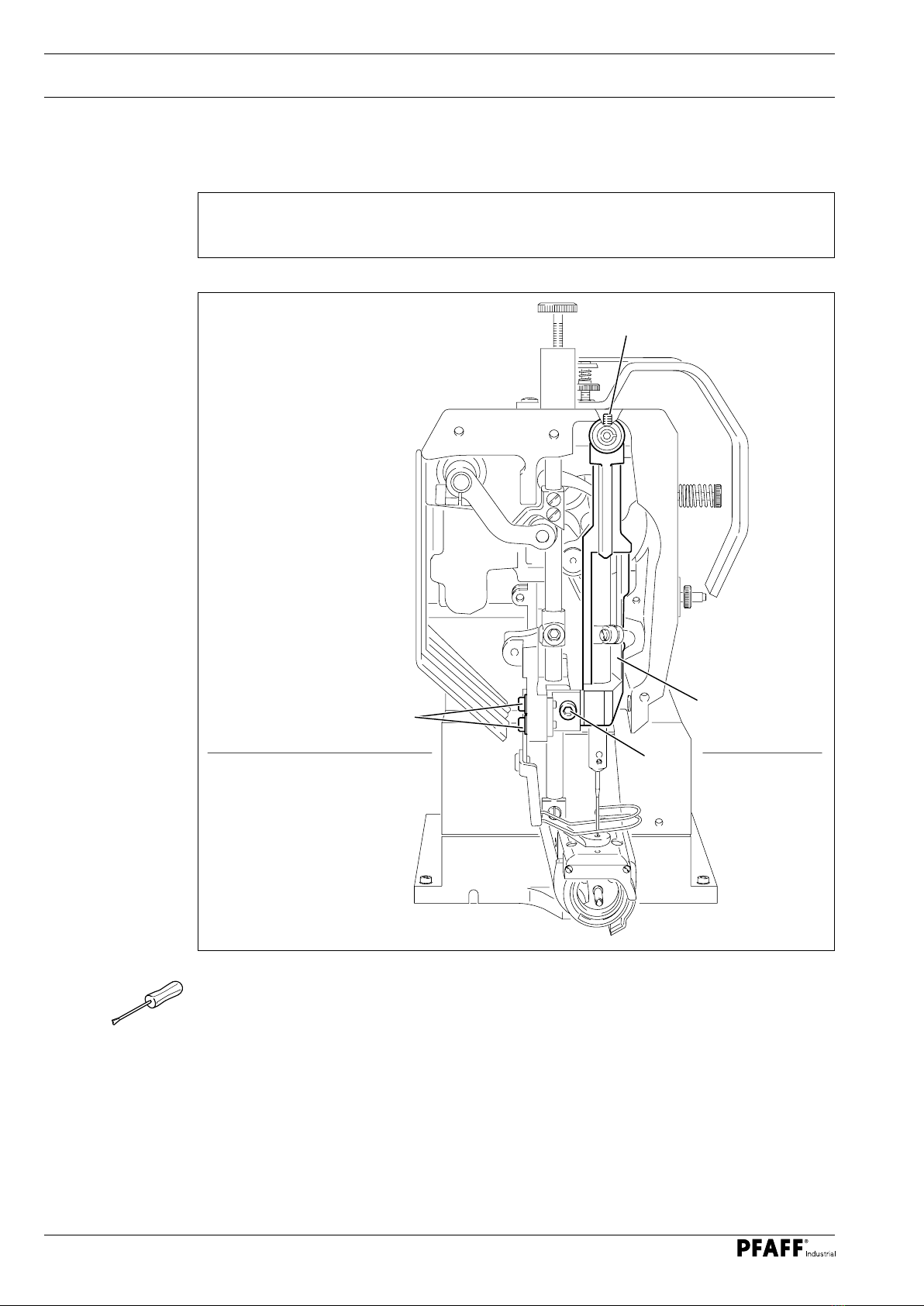

13.04.03 Hook-to-needle clearance, needle bar rise, needle height and needle guard ........................ 8

13.04.04 Presser stroke movement ..................................................................................................... 9

13.04.05 Presser stroke...................................................................................................................... 10

13.04.06 Needle thread tension release............................................................................................. 11

13.04.07 Switching off the needle thread tension release ................................................................. 12

13.04.08 Thread check spring............................................................................................................. 13

13.04.09 Bobbin winder...................................................................................................................... 14

13.04.10 Presser foot pressure .......................................................................................................... 15

13.05 Adjusting thread trimmer -900/51 .................................................................................... 16

13.05.01 Control cam (pre-calibrating) ................................................................................................ 16

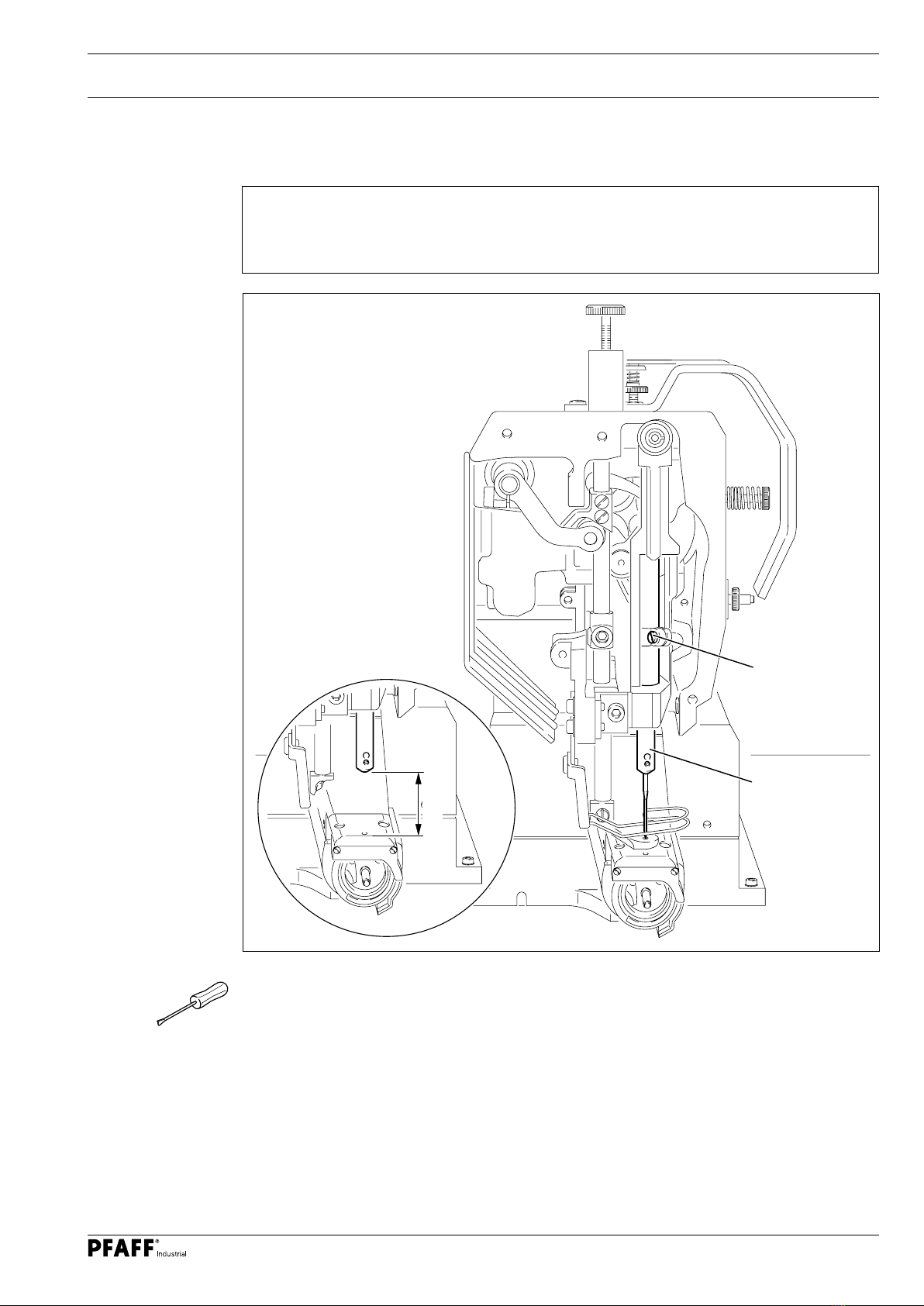

13.05.02 Tripping lever height ............................................................................................................ 17

13.05.03 Feed regulator pin................................................................................................................ 18

13.05.04 Engaging solenoid................................................................................................................ 19

13.05.05 Feed regulator pin height..................................................................................................... 20

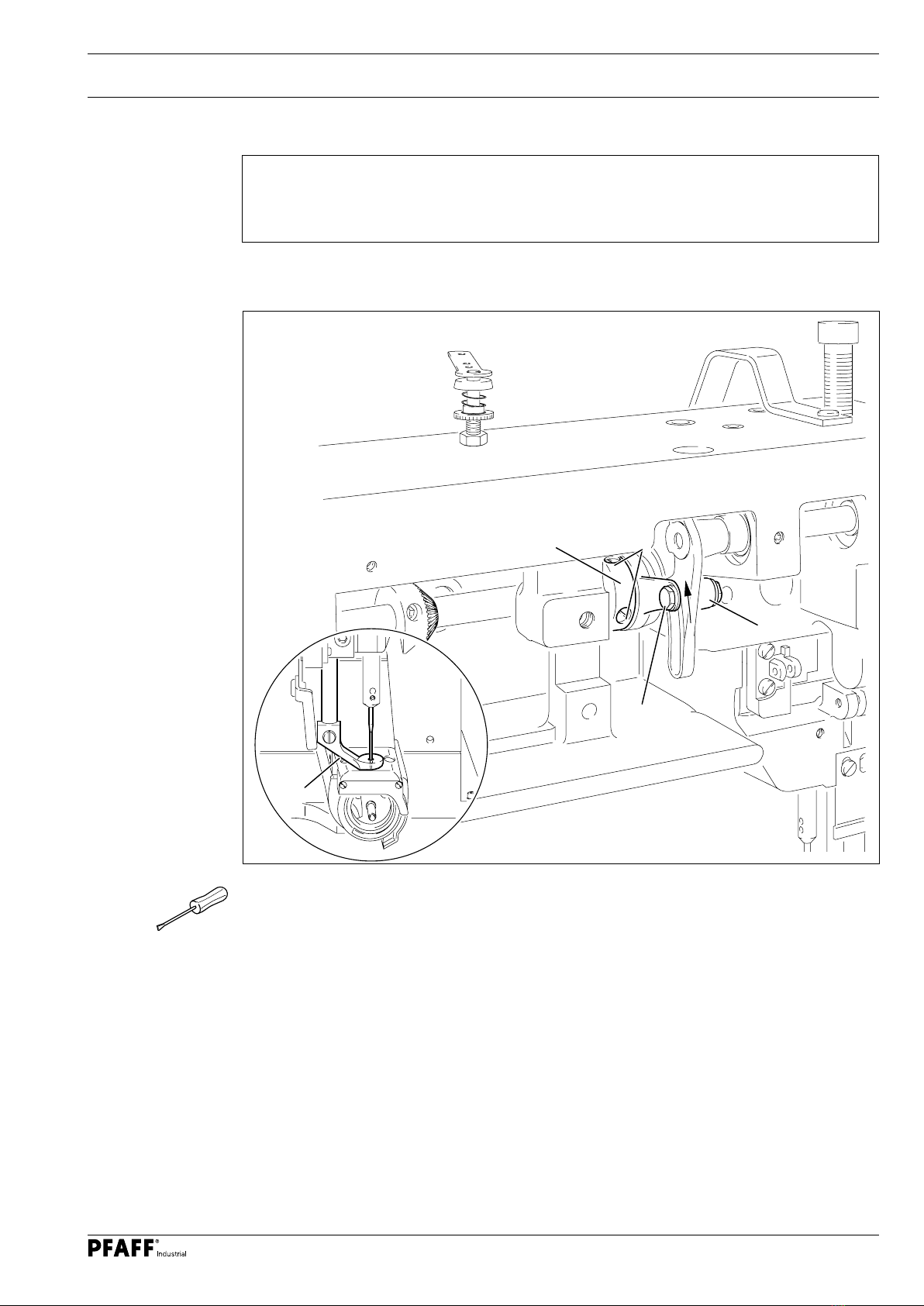

13.05.06 Front turning point of thread catcher ................................................................................... 21

13.05.07 Aligning thread catcher laterally........................................................................................... 22