Index

Contents ..................................................................................Page

1General Notes ...................................................................................................................... 4

1.01 Explanation of the symbols.................................................................................................... 4

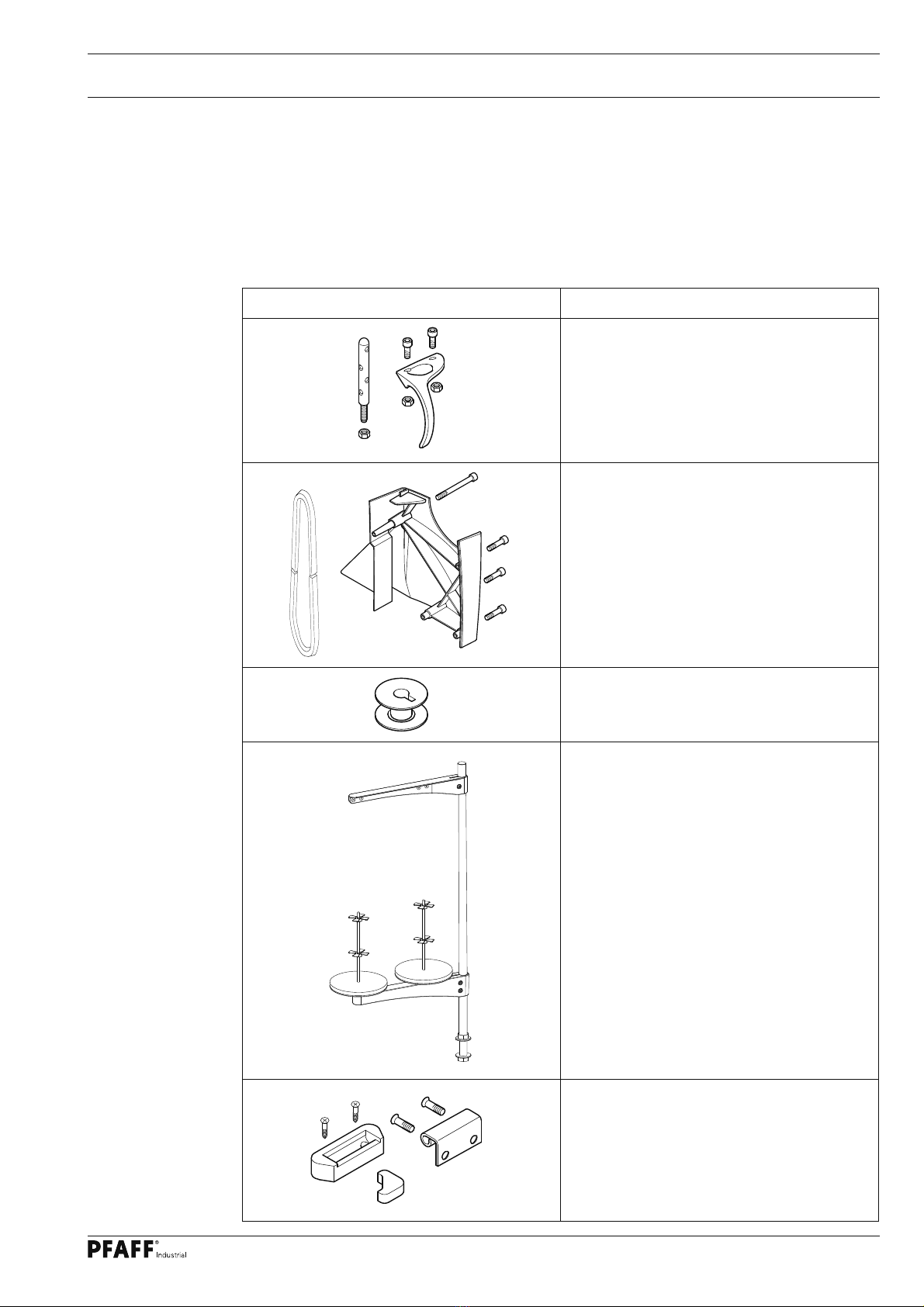

2Scope of delivery ................................................................................................................. 5

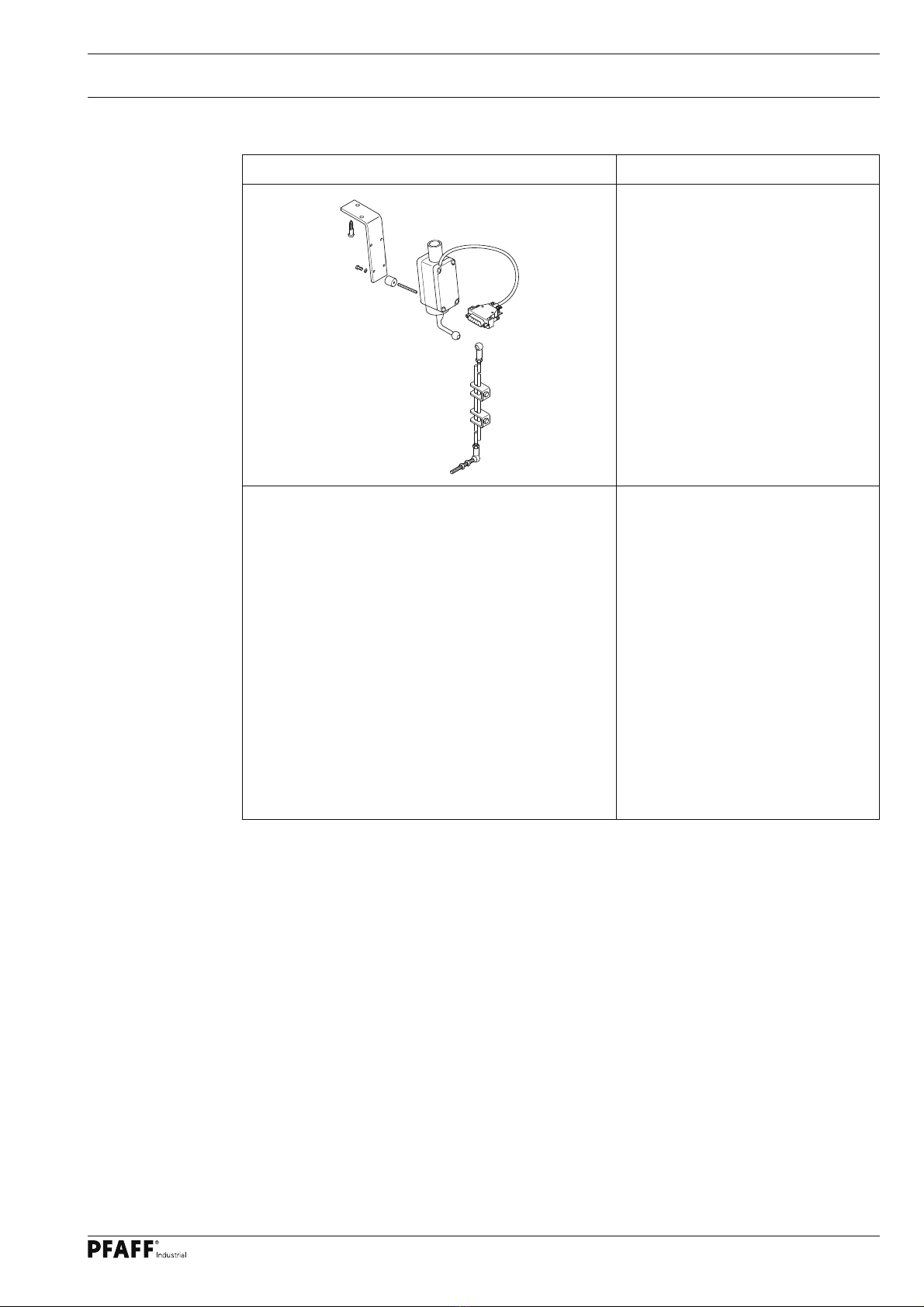

2.01 Sewing machine accessories ................................................................................................5

2.02 Accessories for the sewing machine drive with PicoDrive P45 PD2-L .................................. 7

2.03 Accessories for the sewing machine drive with EcoDrive P74 ED-L...................................... 8

3Stand and table top ........................................................................................................... 10

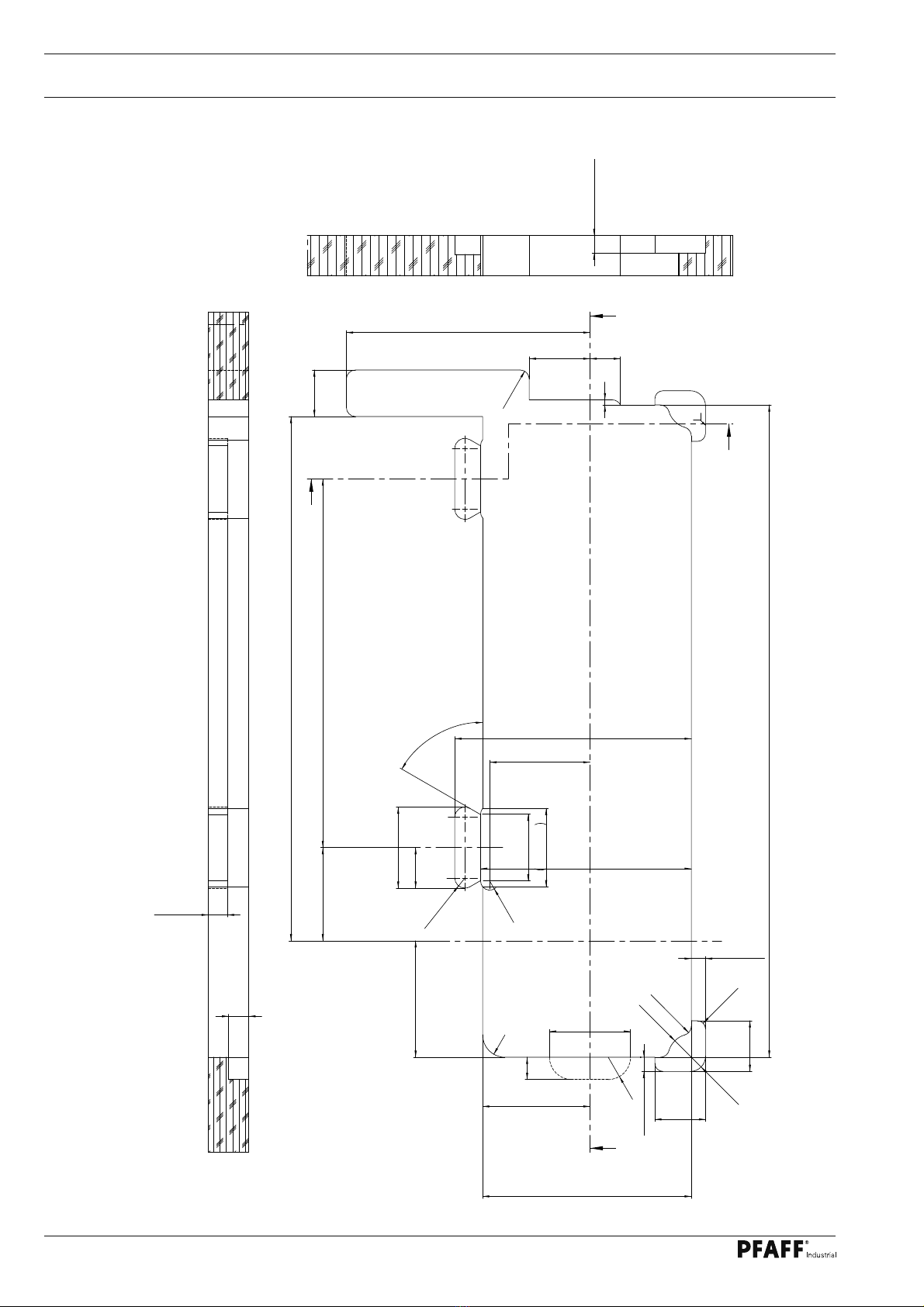

3.01 Table top cutout ................................................................................................................... 10

3.02 Assembly drawing for the table .......................................................................................... 13

3.03 Assembling the stand and table top .................................................................................... 16

3.05 Adjusting the table-top height.............................................................................................. 17

4Assembling the sewing machine drive ............................................................................ 18

4.01 Assembling the motor ......................................................................................................... 18

4.02 Assembling the motor, speedcontrolunit and controlbox .................................................... 19

5LED-Lamp (optional).......................................................................................................... 21

5.01 Assembling the LED lamp ................................................................................................... 21

5.02 Fitting the transformer to the LED lamp .............................................................................. 22

6Installation .......................................................................................................................... 23

6.01 Setting the sewing machine into the stand ......................................................................... 23

6.02 Fitting the V-belt and assembling the bottom belt guard...................................................... 24

6.03 Assembling the thread guide and take-up lever guard......................................................... 25

6.04 Assembling the top V-belt guard and sewing head support................................................. 26

6.05 Mounting the control panel.................................................................................................. 27

6.06 Connecting the plug-in connections and earth cables ......................................................... 28

6.07 Block diagram ...................................................................................................................... 29

6.08 Mounting / connecting the maintenance unit ...............................................................................34

7Commissioning .................................................................................................................. 35

7.01 Switching the machine on/off ..............................................................................................35

7.02 Machine drive home position...............................................................................................36