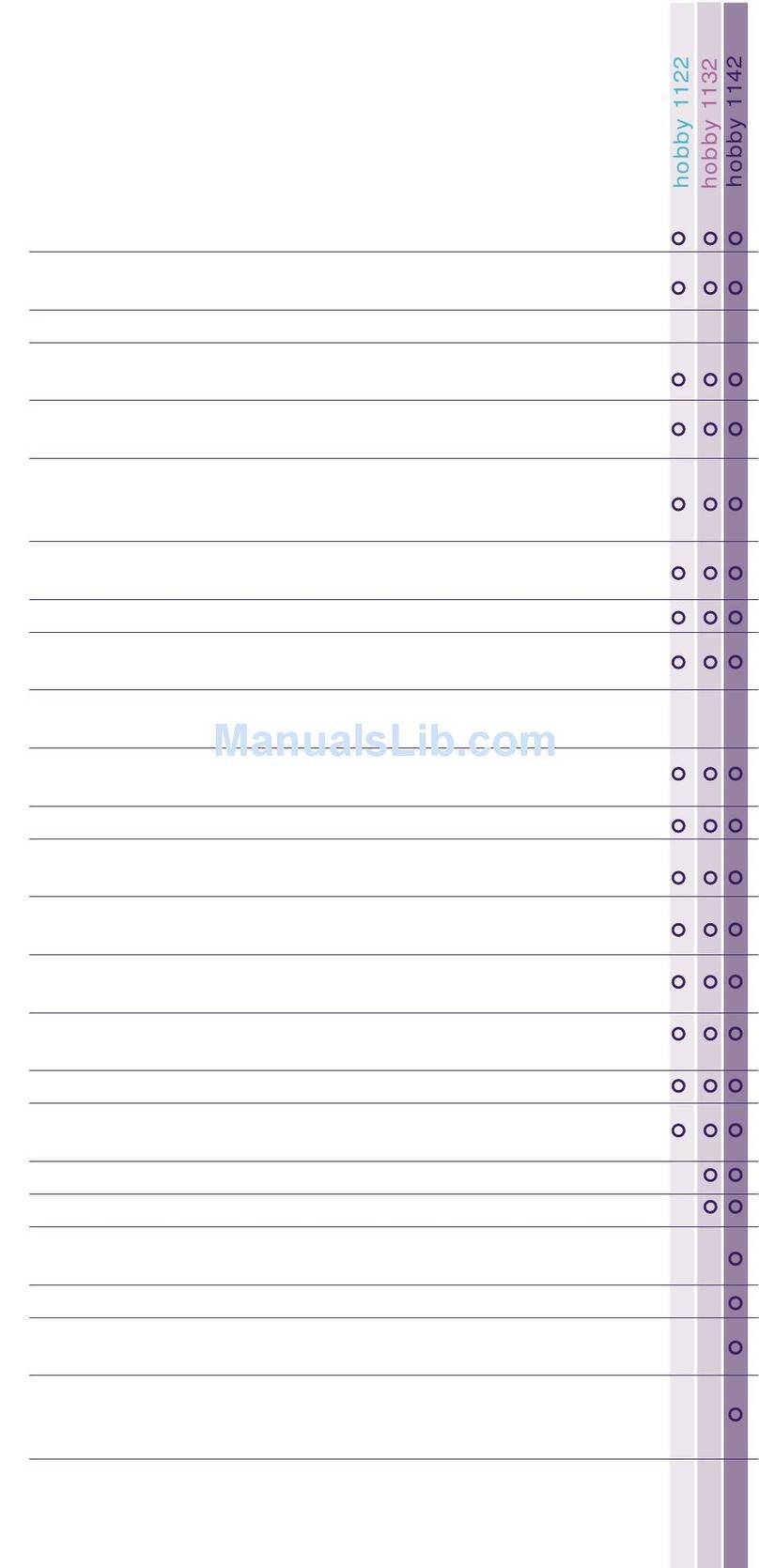

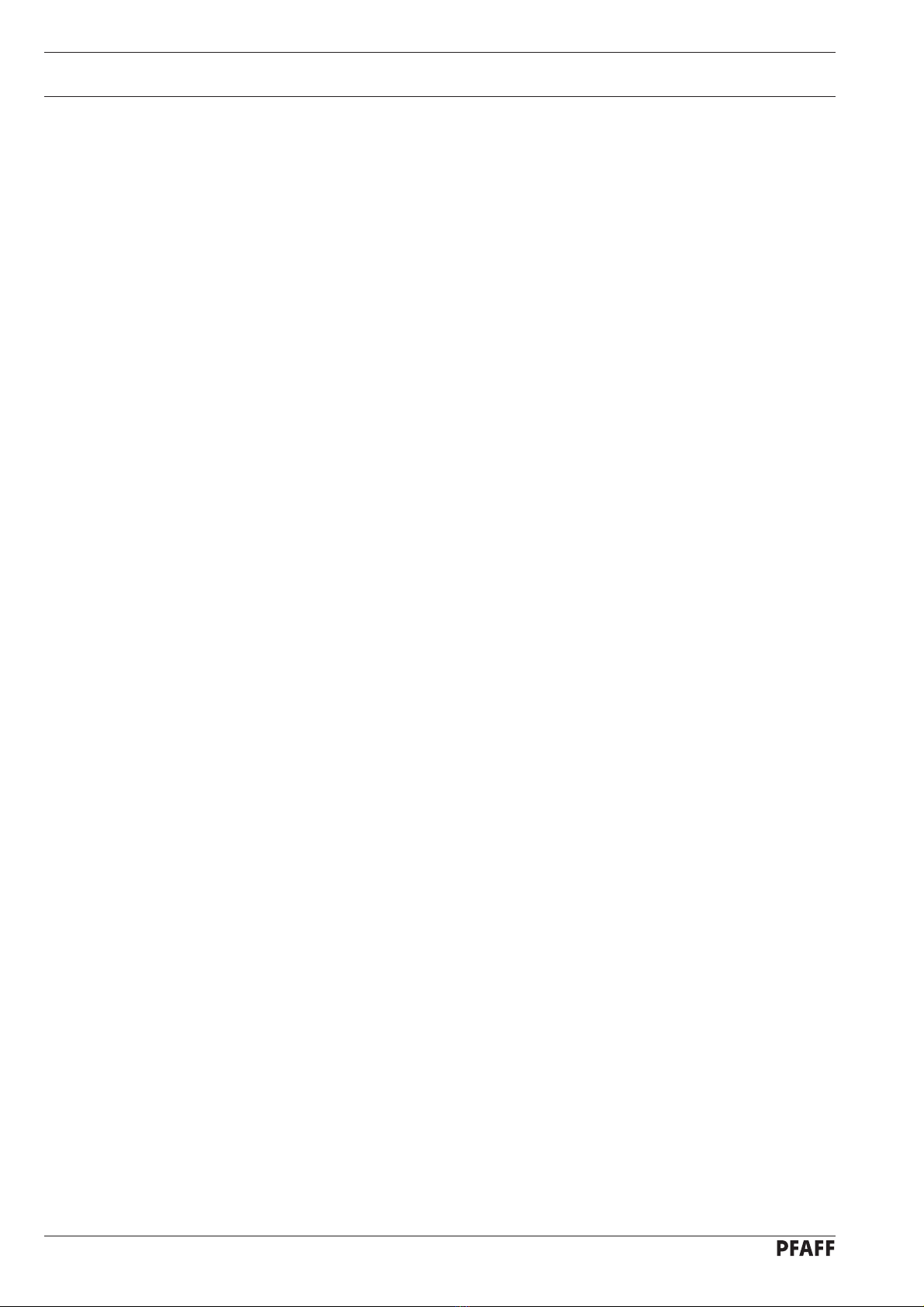

Index

Contents ................................................................................. Chapter - Page

13.04 Control and adjustment aids ....................................................................................... 13 - 2

13.05 Adjusting the basic machine ....................................................................................... 13 - 3

13.05.01 Basic position of the machine ..................................................................................... 13 - 3

13.05.02 Preliminary adjustment of the needle height ............................................................... 13 - 4

13.05.03 Needle in needle-hole centre....................................................................................... 13 - 5

13.05.04 Neutral position of the bottom feed dog ..................................................................... 13 - 6

13.05.05 Feeding motion of the bottom feed dog ..................................................................... 13 - 7

13.05.06 Lifting motion of the bottom feed dog ........................................................................ 13 - 8

13.05.07 Height of the bottom feed dog .................................................................................... 13 - 9

13.05.08 Clearance between presser foot and needle plate ...................................................... 13 - 10

13.05.09 Stop in relation to the presser foot .............................................................................. 13 - 11

13.05.10 Top feed driving and connecting lever ......................................................................... 13 - 12

13.05.11 Neutral position of the top feed dog ............................................................................ 13 - 13

13.05.12 Feeding motion of the top feed dog ............................................................................ 13 - 14

13.05.13 Front linkage rod to top feed drive .............................................................................. 13 - 15

13.05.14 Top feed stroke ........................................................................................................... 13 - 16

13.05.15 Lifting motion of the top feed dog ............................................................................... 13 - 17

13.05.16 Stitch length adjustment ............................................................................................. 13 - 18

13.05.17 Stitch length limitation ................................................................................................ 13 -19

13.05.18 Basic setting of the differential adjustment device ..................................................... 13 - 20

13.05.19 Eccentric hook shaft bearing and hook-to-needle clearance ........................................ 13 - 21

13.05.20 Needle bar rise, readjustment of the needle height and bobbin case position stop .... 13 - 22

13.05.21 Bobbin opener height .................................................................................................. 13 - 23

13.05.22 Adjustment of the bobbin opener ................................................................................ 13 - 24

13.05.23 Bobbin case opener .................................................................................................... 13 - 25

13.05.24 Needle thread tension release .................................................................................... 13 - 26

13.05.25 Thread check spring .................................................................................................... 13 - 27

13.05.26 Bobbin winder ............................................................................................................. 13 - 28

13.05.27 Position of the top feed dog in relation to the sewing foot.......................................... 13 - 29

13.05.28 Top feed dog and sewing foot pressure ...................................................................... 13 - 30

13.05.29 Stitch condensation .................................................................................................... 13 - 31

13.06 Adjusting the thread trimmer ...................................................................................... 13 - 32

13.06.01 Pre-adjusting the control cam ..................................................................................... 13 - 32

13.06.02 Roller lever .................................................................................................................. 13 - 33

13.06.03 Pawl ............................................................................................................................ 13 - 34

13.06.04 Engaging solenoid ....................................................................................................... 13 -35

13.06.05 Release lever ..............................................................................................................13-36

13.06.06 Engaging lever ............................................................................................................ 13 - 37

13.06.07 Lateral adjusting of the thread catcher ........................................................................ 13 - 38

13.06.08 Front reversal point of the thread catcher ................................................................... 13 - 39

13.06.09 Re-adjusting the control cam ...................................................................................... 13 - 40

13.06.10 Retaining spring .......................................................................................................... 13 - 41

13.06.11 Knife to needle clearance ............................................................................................ 13 - 42

13.06.12 Manual trimming control ............................................................................................. 13 - 43