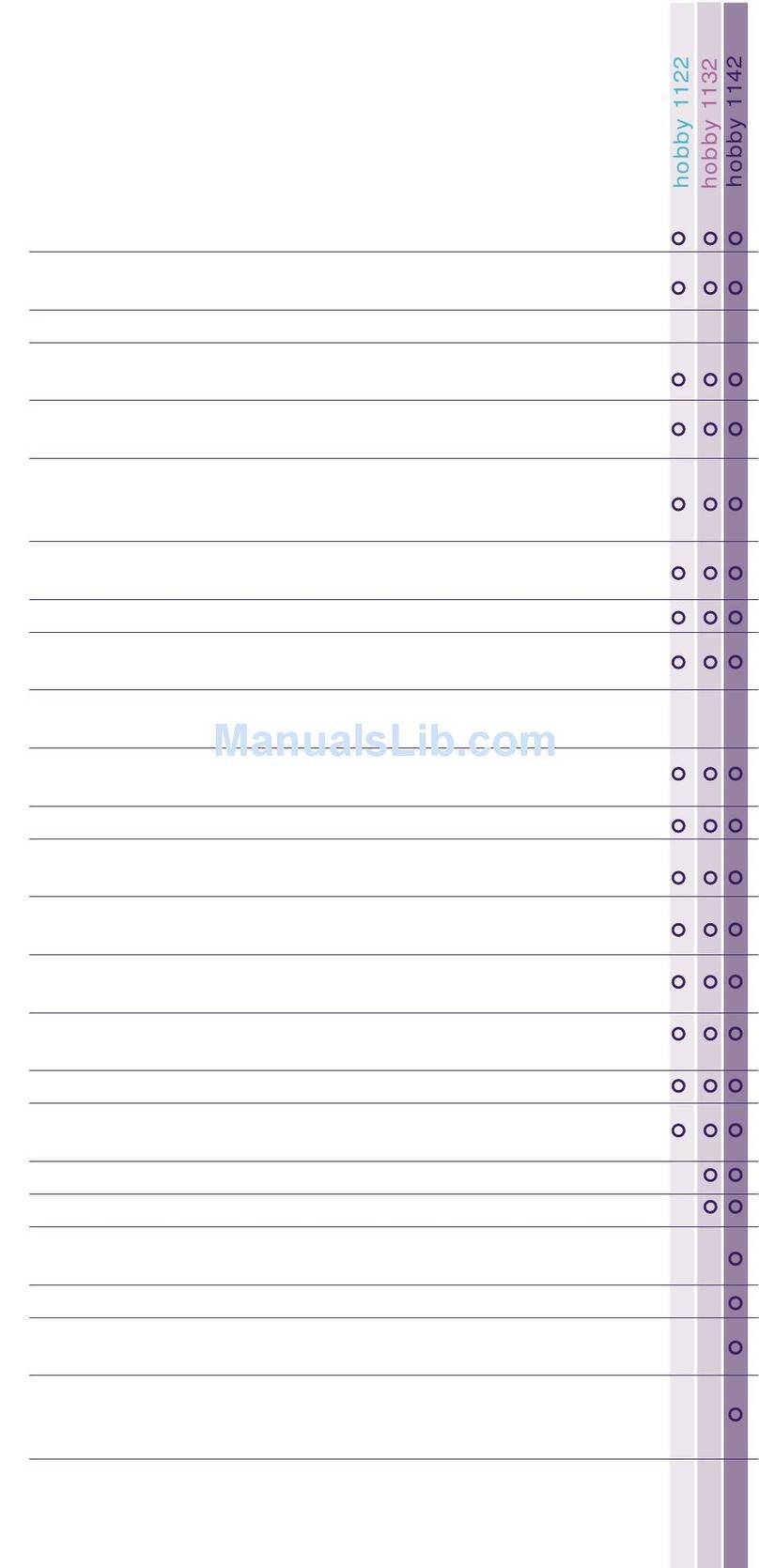

Table of Contents

Contents ..................................................................................Page

8.02.02 Mounting the flange motor on the machine ........................................................................ 25

8.02.03 Mounting the machine cover ............................................................................................... 25

8.02.04 Connecting the plug-in connections and ground cable ........................................................ 26

8.02.05 Machine drive home position / fitting the toothed belt ........................................................ 27

8.02.06 Mounting the flange motor belt guard................................................................................. 28

8.02.07 Connecting the safety switch .............................................................................................. 29

8.02.08 Checking the start inhibitor function .................................................................................... 29

8.03 Assembling the reel stand ................................................................................................... 30

8.04 Initial start-up ....................................................................................................................... 30

8.05 Switching the machine on / off ............................................................................................ 30

9Set-up.................................................................................................................................. 31

9.01 Inserting the needle ............................................................................................................ 31

9.02 Winding the bobbin thread, adjusting the thread tension.................................................... 32

9.03 Removing / inserting the bobbin case.................................................................................. 33

9.04 Inserting the bobbin case, adjusting the bobbin thread tension .......................................... 33

9.05 Threading the needle thread / adjusting the needle thread tension.................. 34

9.06 Selecting a program number ....................................................................................... 35

9.07 Setting stitch lengths ........................................................................................................... 36

9.08 Entering start and end backtacks......................................................................................... 37

9.09 Switching on / setting the bobbin thread monitoring using stitch counting............................ 39

9.10 Entering / changing the code number................................................................................... 41

9.11 Setting the control panel...................................................................................................... 43

9.12 Inserting and removing the SD memory card ..................................................................... 44

10 Sewing ................................................................................................................................ 45

10.01 Manual sewing..................................................................................................................... 45

10.02 Sewing with fixed programs ................................................................................................ 47

10.03 Programmed sewing............................................................................................................ 49

10.03.01 Program interruption ............................................................................................................ 51

10.04 Error messages.................................................................................................................... 51

11 Input .................................................................................................................................... 52

11.01 Entering seam programs .....................................................................................................53

11.01.01 Basic seam program input settings...................................................................................... 53

11.01.02 Seam program input via the “Create/correct program” function......................................... 55

11.01.03 Seam program input via the “Teach-in” function ................................................................. 57

11.02 Examples for setting seam programs .................................................................................. 59

11.02.01 Examples of seam program input using the “Create/correct program” function ................ 59

11.02.02 Example for seam program input via the “Teach-in” function.............................................. 61

11.03 Managing seam programs ................................................................................................... 63

11.04 Parameter settings............................................................................................................... 65

11.04.01 Overview of parameter functions ........................................................................................ 65

11.04.02 Example of a parameter entry ............................................................................................. 66

11.04.03 List of parameters for control P320 and 321 ....................................................................... 67