Index

Contents ..................................................................................Page

1Proper use............................................................................................................................. 4

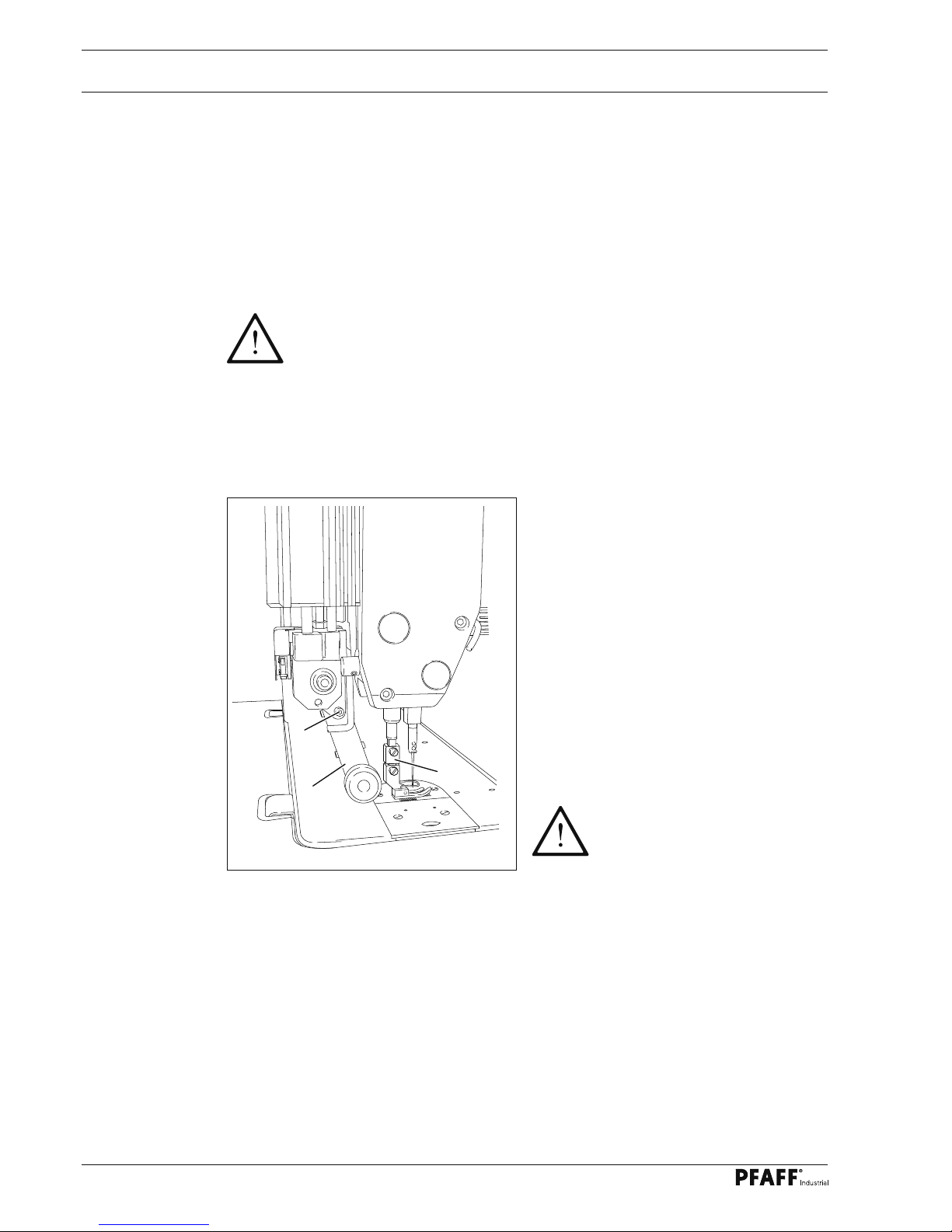

1.01 Using standard presser feet .................................................................................................. 4

2Controls ................................................................................................................................ 5

2.01 Puller functions ...................................................................................................................... 5

2.02 Aligning the puller .................................................................................................................. 5

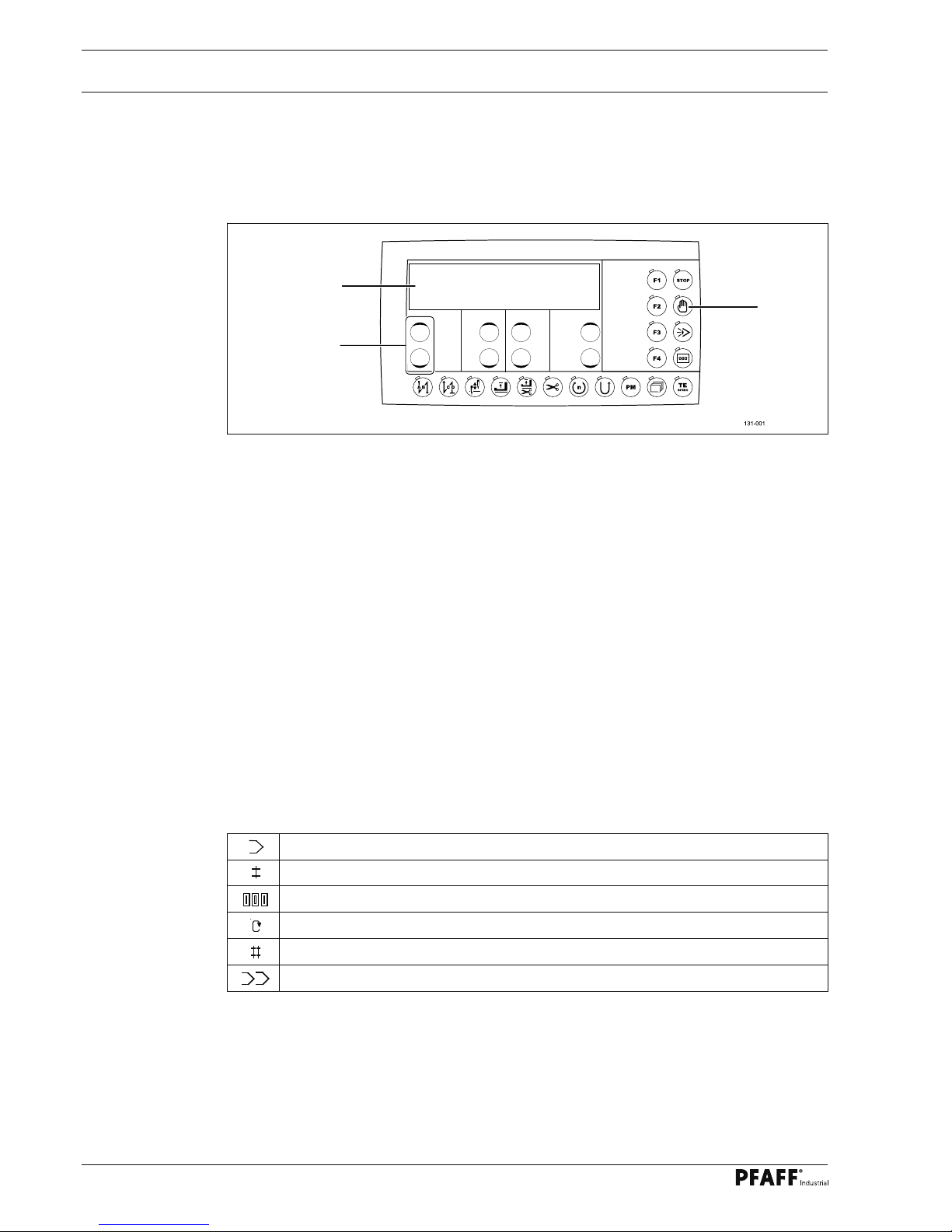

2.03 Control panel.......................................................................................................................... 6

2.03.01 Symbols on the display .......................................................................................................... 6

2.03.02 Plus-minus keys ..................................................................................................................... 7

2.03.03 Function keys ......................................................................................................................... 7

3Commissioning .................................................................................................................... 9

3.01 Basic position of the machine drive ....................................................................................... 9

4Setting up ........................................................................................................................... 10

4.01 Entering the puller feed stroke (stitch length) ...................................................................... 10

4.02 Setting the puller pressure................................................................................................... 10

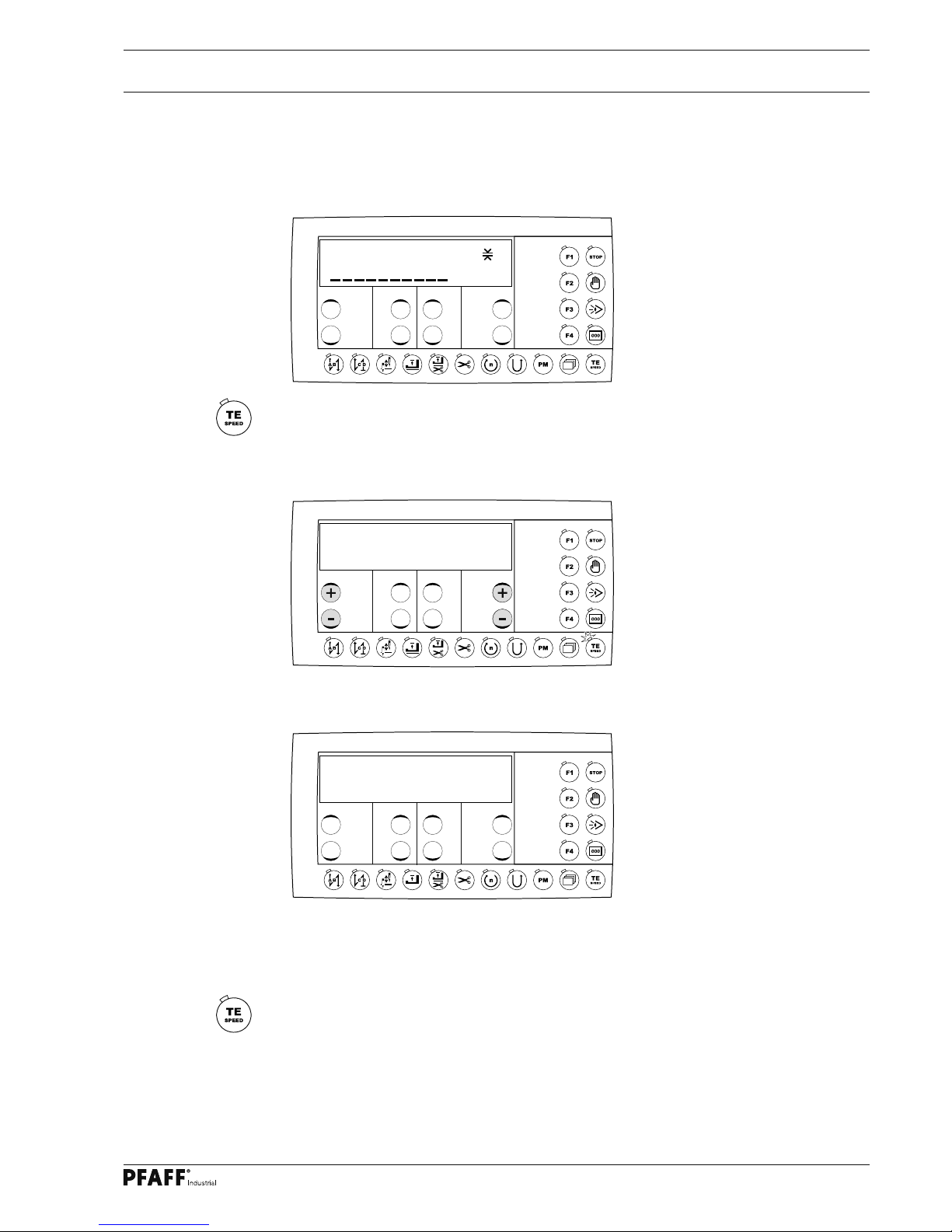

4.03 Entering the maximum speed ............................................................................................. 11

4.04 Entering the start and end backtacks................................................................................... 11

4.05 Setting the stitch counting function for the bobbin thread control....................................... 12

5Sewing ................................................................................................................................ 13

5.01 Manual sewing..................................................................................................................... 13

5.02 Programmed sewing............................................................................................................ 14

5.03 Error messages.................................................................................................................... 15

5.03.01 Description of the error messages ...................................................................................... 15

6Parameter input.................................................................................................................. 16

6.01.01 Example of how to enter the parameters............................................................................ 16

6.01.02 Selecting the user level........................................................................................................ 17

6.02 Parameter list....................................................................................................................... 18

7Service functions................................................................................................................ 27

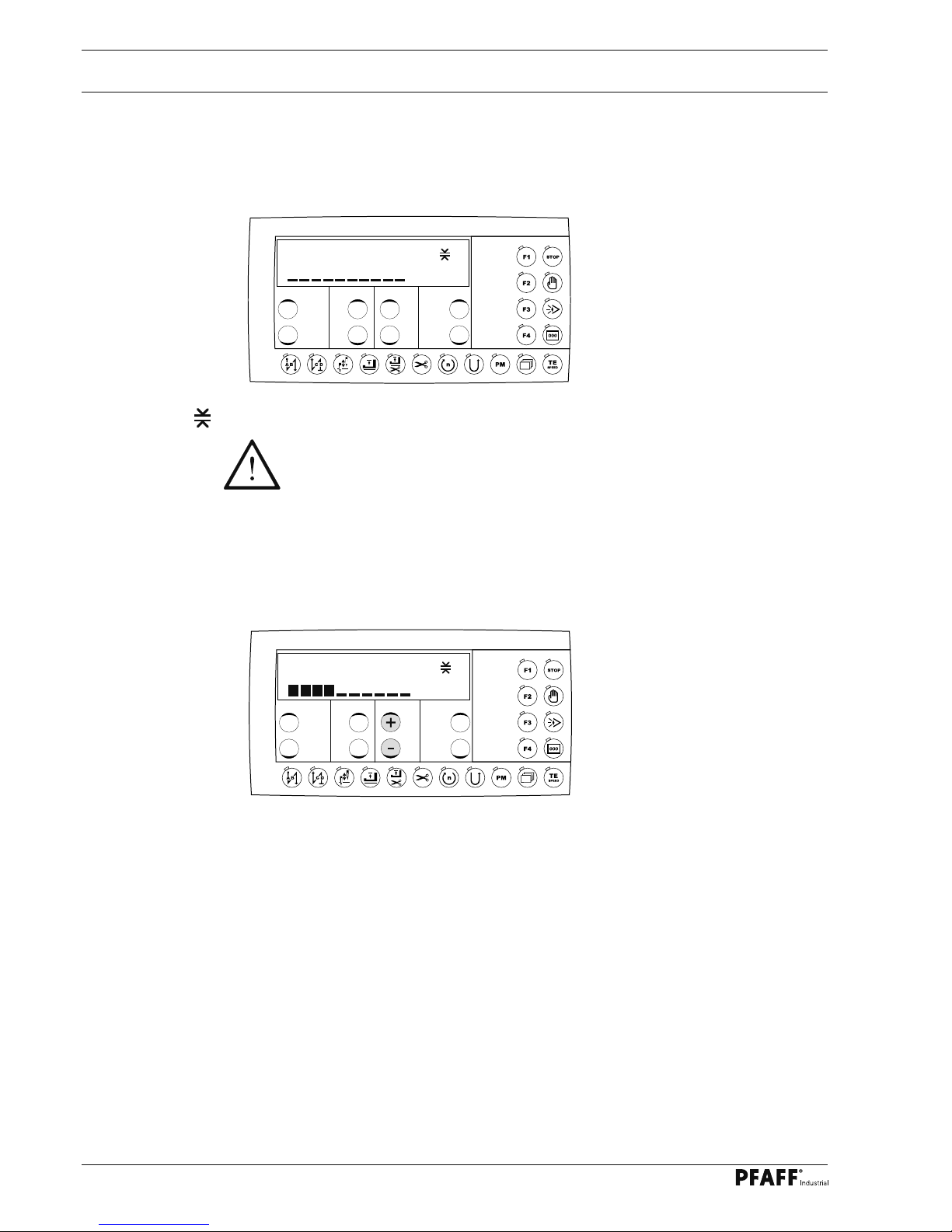

7.01 Reset / Cold start ................................................................................................................. 27

7.02 Hardware-test ...................................................................................................................... 28

7.02.01 Test block 1 – inputs ............................................................................................................ 28

7.02.02 Test block 2 – outputs .......................................................................................................... 29

7.02.03 Test block 3 – speed control unit ......................................................................................... 29

7.02.04 Test block 4 – actual value transmitter .................................................................................30

7.02.05 Test block 5 – light barrier .................................................................................................... 30

7.02.06 Test block 6 – thread monitor (only on subclass -926/06) .................................................... 31

7.02.07 Test block 7. - puller ........................................................................................................... 31

7.02.08 Test block 8 – data transfer ............................................................................................... 32

8Circuit diagrams................................................................................................................. 33