Pfaff 487 User manual

Other Pfaff Sewing Machine manuals

Pfaff

Pfaff hobbylock 4762 User manual

Pfaff

Pfaff hobbylock 2.5 User manual

Pfaff

Pfaff 2481-980/30 PLUSLINE User manual

Pfaff

Pfaff creative 1371 User manual

Pfaff

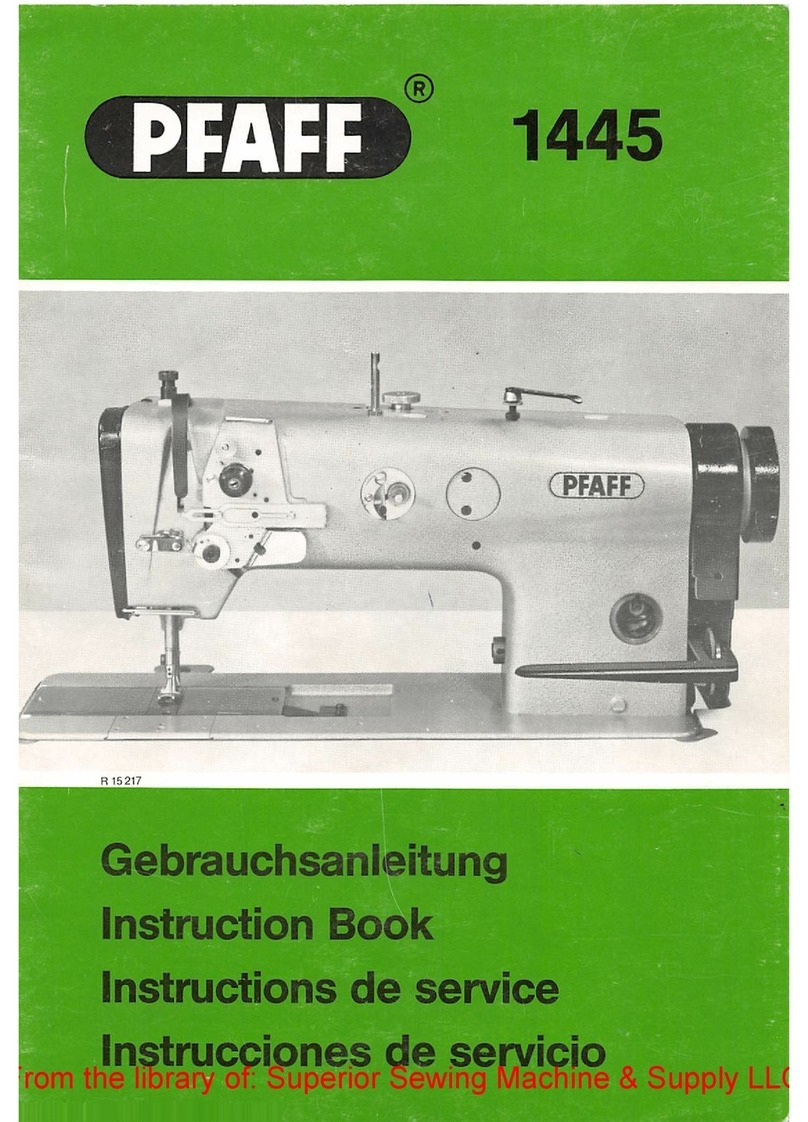

Pfaff 1445 User manual

Pfaff

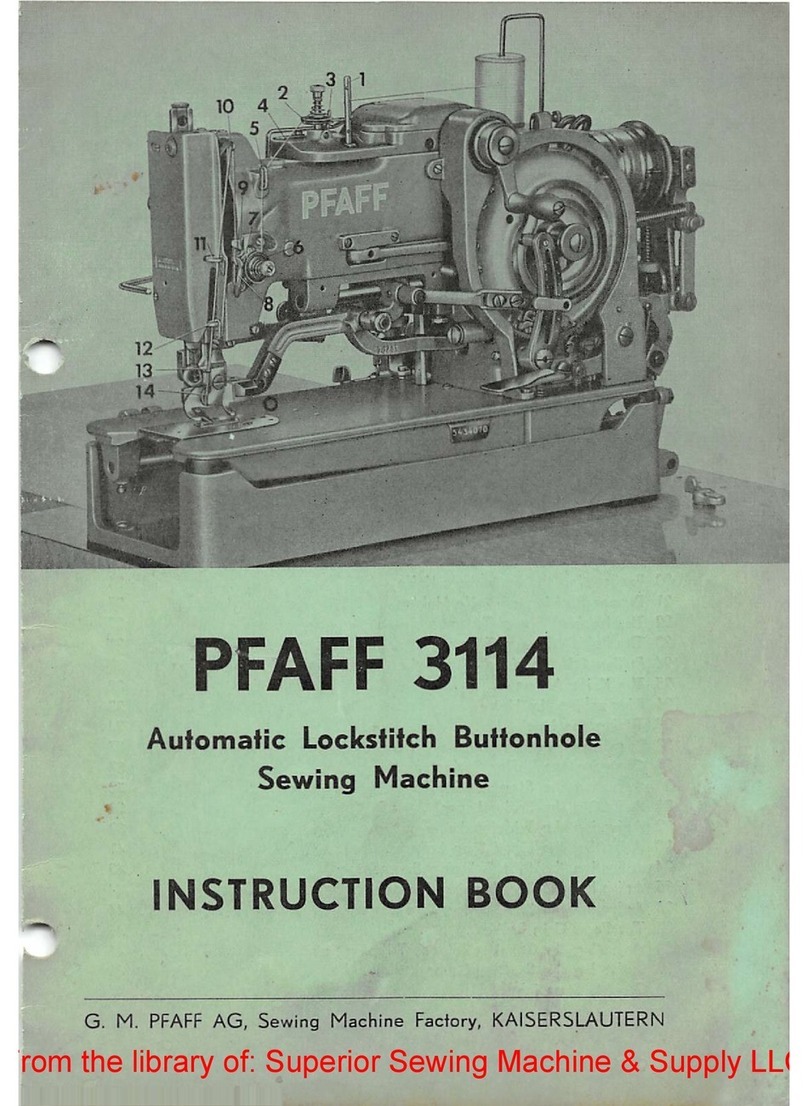

Pfaff 3114 User manual

Pfaff

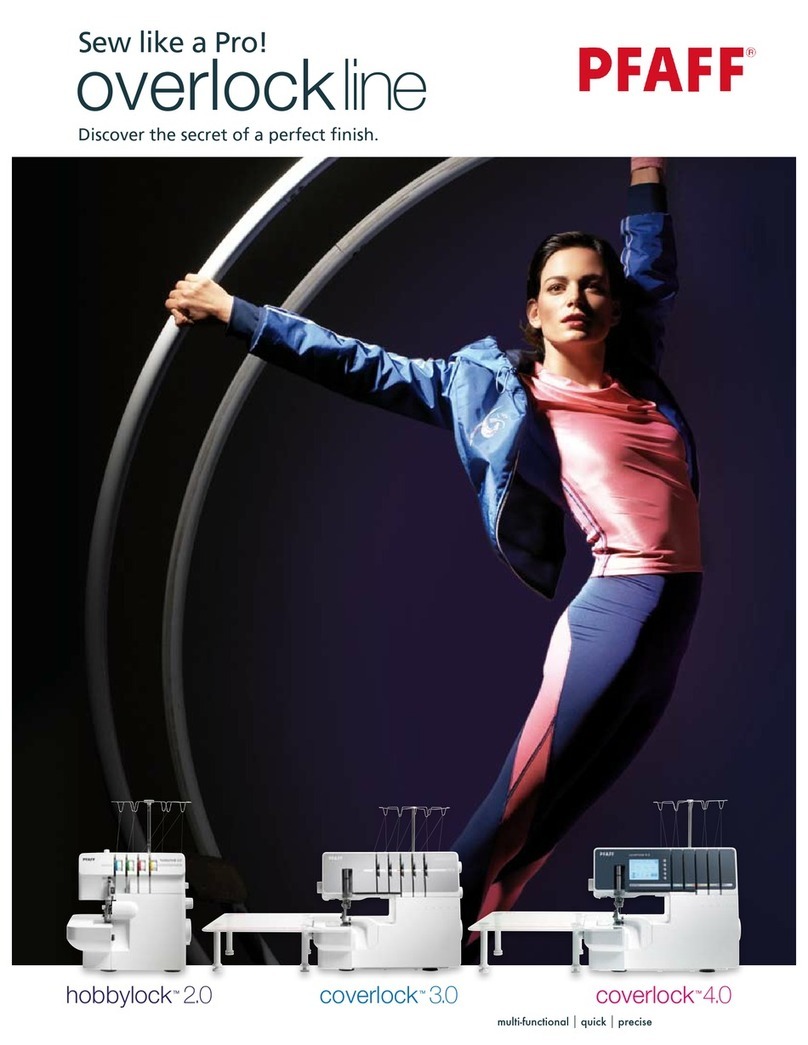

Pfaff COVERLOCK 3.0 - User manual

Pfaff

Pfaff Sewing Machine User manual

Pfaff

Pfaff synchrotronic 1229 User manual

Pfaff

Pfaff 571 User manual

Pfaff

Pfaff 9 User manual

Pfaff

Pfaff 1163 User manual

Pfaff

Pfaff ClassicStyle 1525 User manual

Pfaff

Pfaff HD SCREEN User manual

Pfaff

Pfaff Automatic 260 User manual

Pfaff

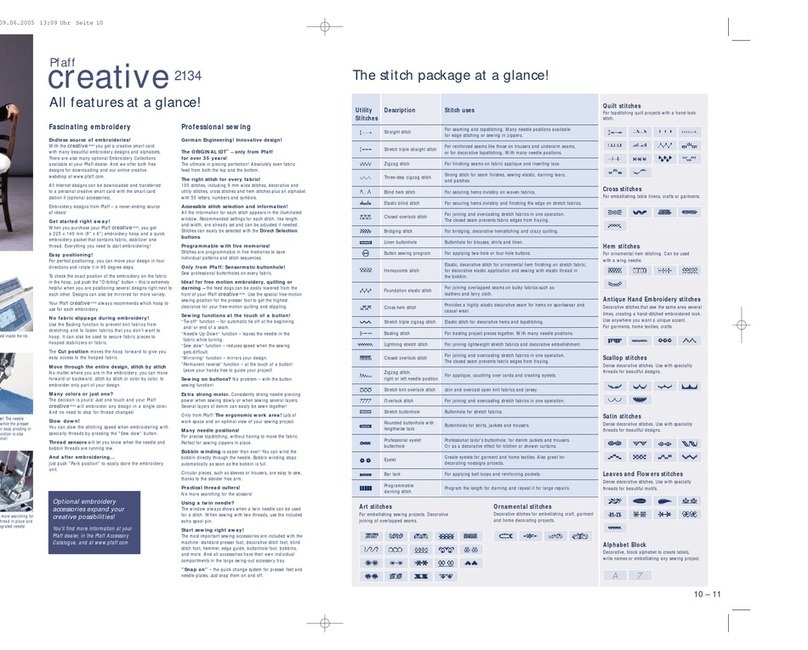

Pfaff Creative 2134 User manual

Pfaff

Pfaff creative sensation User manual

Pfaff

Pfaff dorina 72 User manual

Pfaff

Pfaff 1295 Guide

Pfaff

Pfaff creative 3.0 User manual