Index

Contents ................................................................................ Page

1Adjustment ........................................................................................................................... 4

1.01 Notes on adjustment ............................................................................................................. 4

1.02 Tools, gauges and other accessories for adjusting ............................................................... 4

1.03 Abbreviations ......................................................................................................................... 4

1.04 Explanation of the symbols.................................................................................................... 4

1.05 Adjusting the basic machine .................................................................................................. 5

1.05.01 Basic position of the balance wheel (adjustment aid)............................................................ 5

1.05.02 Balance weight ...................................................................................................................... 6

1.05.03 Zero position of the unison feed ........................................................................................... 7

1.05.04 Feeding motion of the unison feed ....................................................................................... 8

1.05.05 Lifting motion of the bottom feed dog ...................................................................................9

1.05.06 Height of the bottom feed dog ............................................................................................ 11

1.05.07 Feeding stroke difference .................................................................................................... 12

1.05.08 Preliminary adjustment of the needle height....................................................................... 13

1.05.09 Needle rise, hook clearance, needle height and needle guard ............................................ 14

1.05.10 Top feed stroke .................................................................................................................... 16

1.05.11 Top-feed lifting motion ......................................................................................................... 17

1.05.12 Adjusting the potentiometer for speed reduction................................................................ 18

1.05.12.01 On machines with drive P74 ED-L........................................................................................ 19

1.05.12.02 On machines with drive PF 321........................................................................................... 19

1.05.13 Bobbin case opener stroke ................................................................................................. 19

1.05.14 Adjusting the shortened trim stitch......................................................................................20

1.05.15 Bobbin winder...................................................................................................................... 21

1.05.16 Thread check spring and thread regulator............................................................................ 22

1.05.17 Sewing foot pressure........................................................................................................... 23

1.05.18 Lubrication ........................................................................................................................... 24

1.05.19 Limiting the stitch length ..................................................................................................... 25

1.05.20 Speed reduction................................................................................................................... 26

1.05.21 Re-engaging the slip-clutch.................................................................................................. 27

1.06 Adjusting the thread trimmer -900/81.................................................................................. 28

1.06.01 Resting position of roller lever/radial position of control cam .............................................. 28

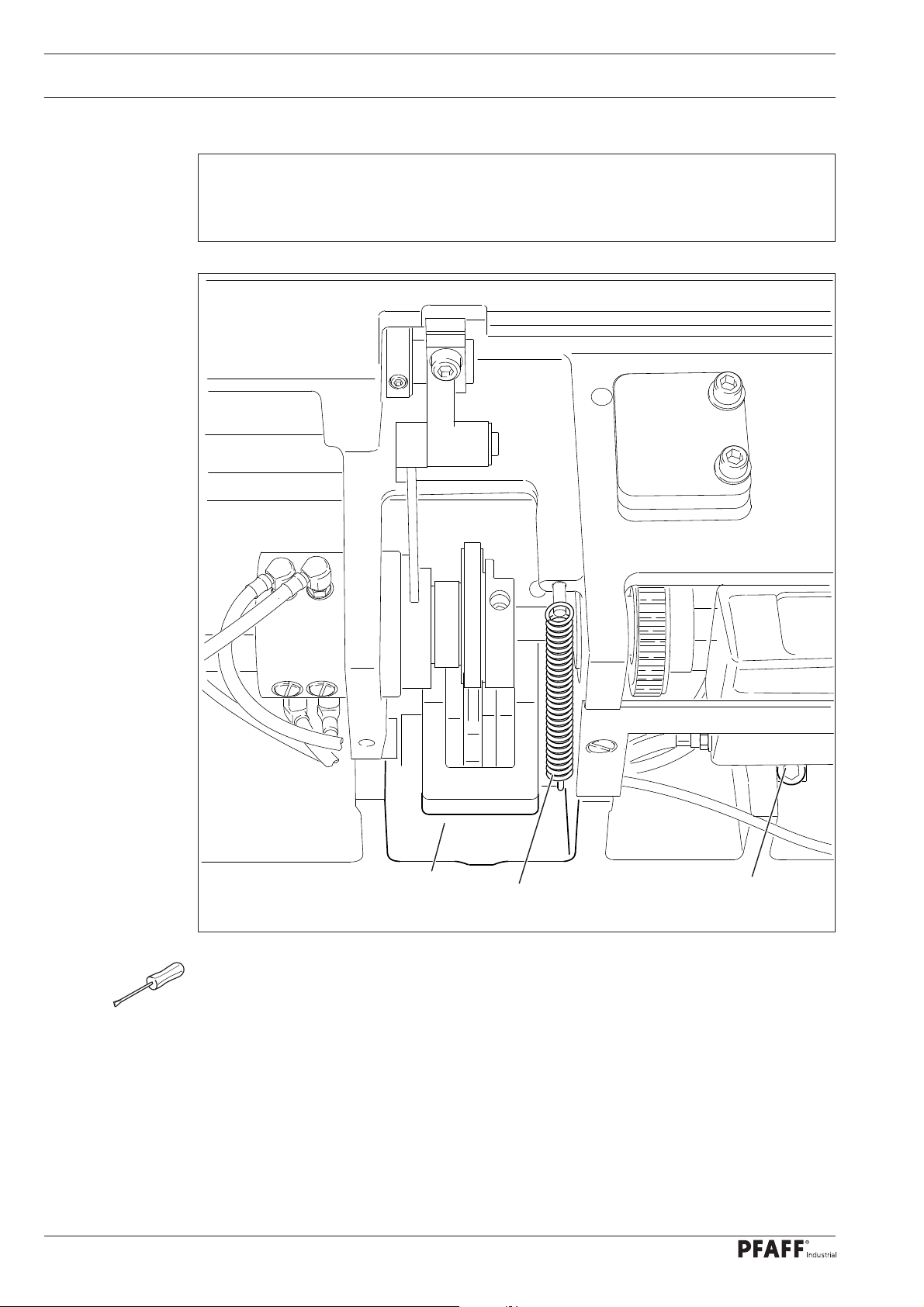

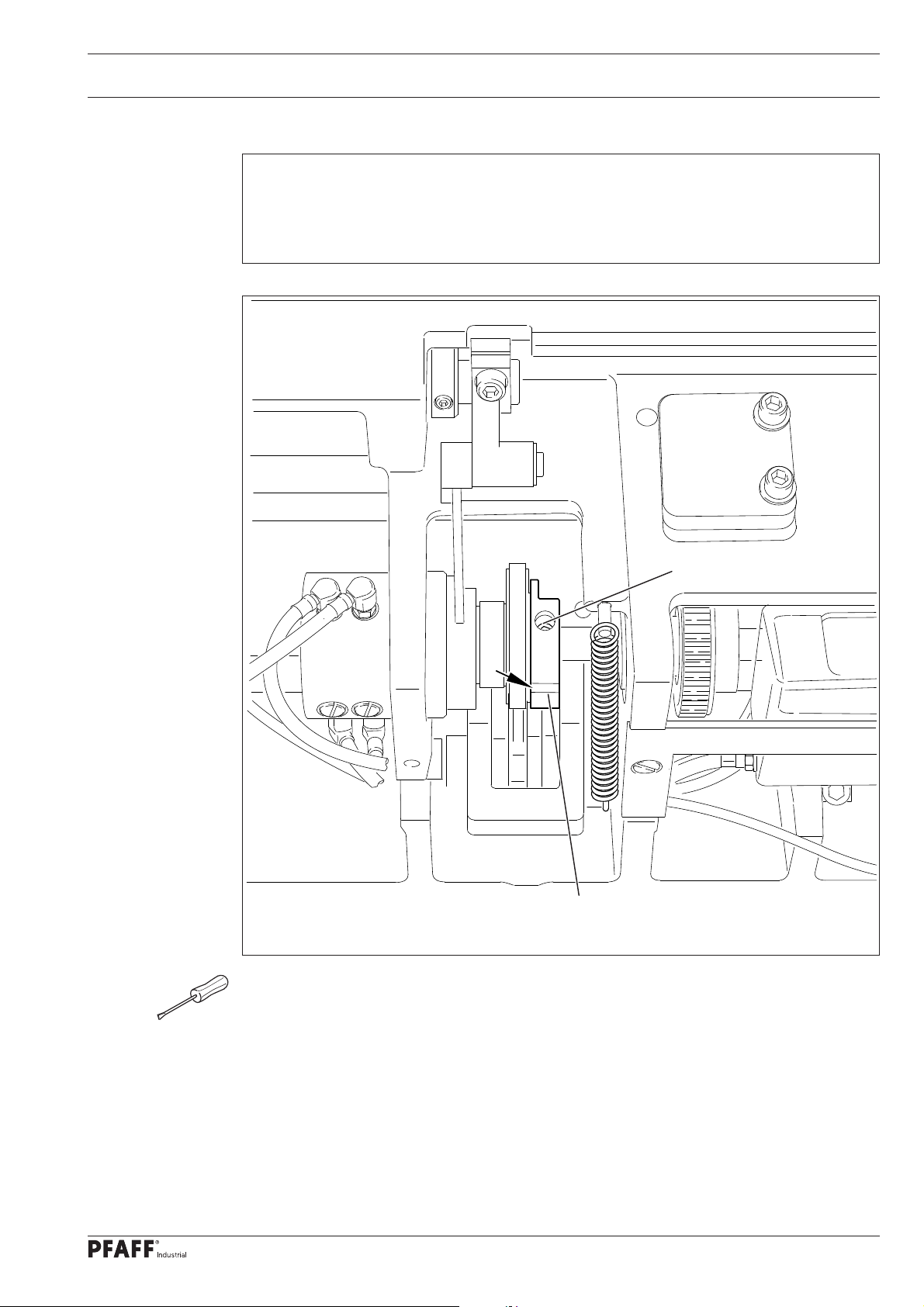

1.06.02 Position and height of the thread catcher ............................................................................ 29

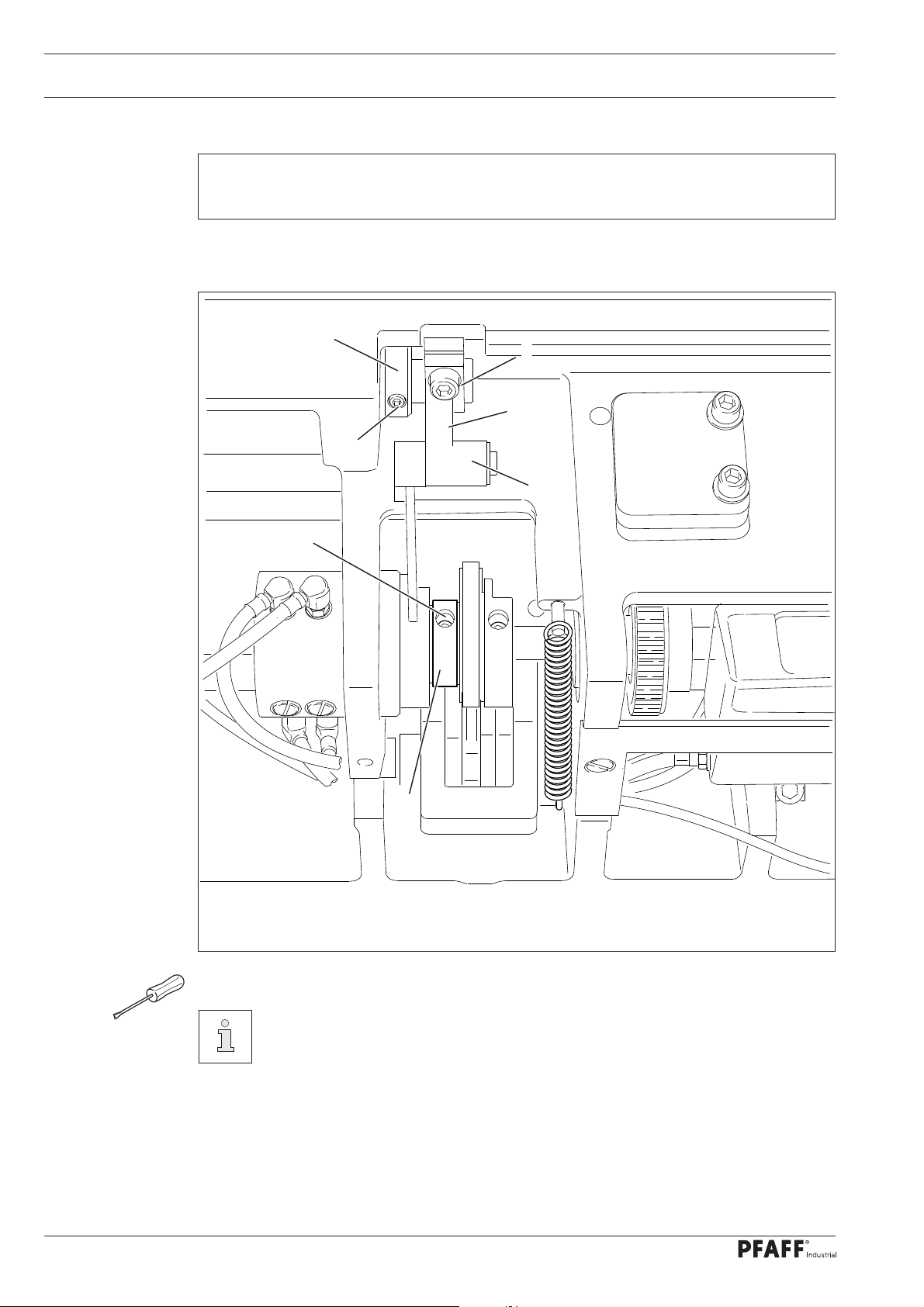

1.06.03 Knife pressure...................................................................................................................... 30

1.06.04 Bobbin thread clamp spring ................................................................................................. 31

1.06.05 Manual cutting test .............................................................................................................. 32