Table of Contents

Contents ..................................................................................Page

1Safety .................................................................................................................................... 5

1.01 Directives............................................................................................................................... 5

1.02 General safety instructions .................................................................................................... 5

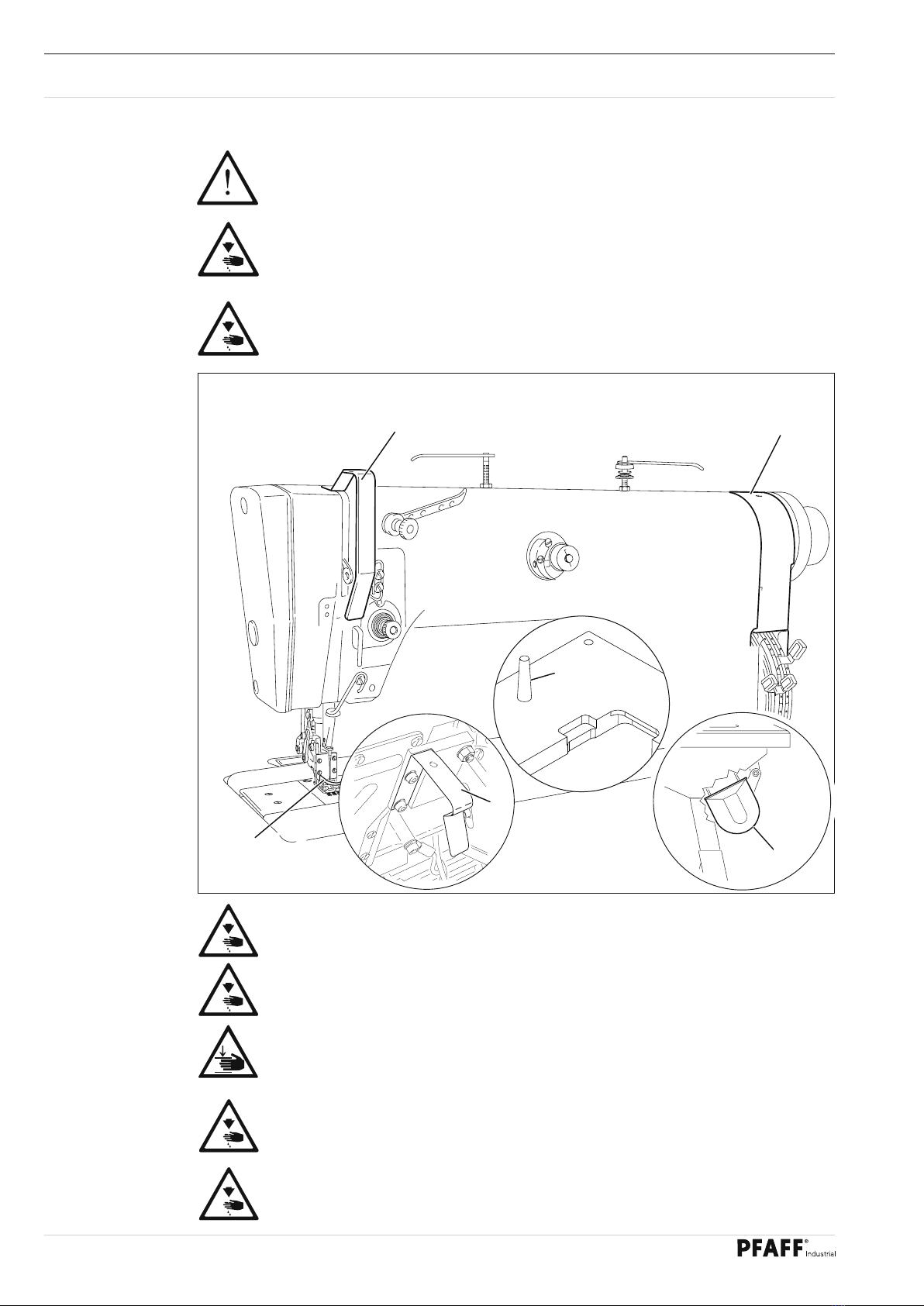

1.03 Safety symbols ...................................................................................................................... 6

1.04 Special points of attention for the owner-operator................................................................. 6

1.05 Operating personnel and technical staff ................................................................................ 7

1.05.01 Operating personnel .............................................................................................................. 7

1.05.02 Technical staff ........................................................................................................................ 7

1.06 Danger warnings.................................................................................................................... 8

2Proper Use............................................................................................................................ 9

3Technical Datas................................................................................................................. 10

3.01 PFAFF 487............................................................................................................................ 10

4Disposal of the Machine .....................................................................................................11

5Transport, Packaging and Storage.................................................................................... 12

5.01 Transport to the customer's premises................................................................................. 12

5.02 Transport within the customer's premises .......................................................................... 12

5.03 Disposal of the packaging materials .................................................................................... 12

5.04 Storage ................................................................................................................................ 12

6Work Symbols .................................................................................................................... 13

7Operating Controls ............................................................................................................ 14

7.01 Main switch ......................................................................................................................... 14

7.02 Keys on the machine head (only in machines with backtacking system -911/..) .................. 14

7.03 Pedal .................................................................................................................................... 15

7.04 Hand lever to raise the sewing foot ..................................................................................... 15

7.05 Lever for stitch length regulation and reverse sewing ......................................................... 16

7.06 Adjusting lever for the top feed............................................................................................ 16

7.07 Edge trimmer -731/11 .......................................................................................................... 17

7.08 Knee lever (in machines without backtacking system -911/..) .............................................. 17

7.09 Knee switch (only with subclass -918/14) ............................................................................ 18

7.10 Control panel (only in machines with P40 CD)..................................................................... 18

8Set-up and Initial Commissioning .................................................................................... 19

8.01 Set-up .................................................................................................................................. 19

8.01.01 Setting the table height........................................................................................................ 19

8.01.02 Inserting the sewing machine into the stand....................................................................... 20

8.01.04 Tensioning the V-belt............................................................................................................ 21

8.01.06 Assembling the upper V-belt guard ...................................................................................... 22

8.01.07 Mounting the synchroniser .................................................................................................. 23

8.01.08 Assembling the anti-tipping device ...................................................................................... 23