Index

Contents ................................................................................ Page

1Adjustment ........................................................................................................................... 5

1.01 Notes on adjustment ............................................................................................................. 5

1.02 Tools, gauges and other accessories for adjusting ............................................................... 5

1.03 Abbreviations ......................................................................................................................... 5

1.04 Explanation of the symbols.................................................................................................... 5

1.05 Adjusting the basic machine .................................................................................................. 6

1.05.01 Basic position of the balance wheel (adjustment aid)............................................................ 6

1.05.02 Balance weight ...................................................................................................................... 7

1.05.03 Needle position in the direction of sewing ............................................................................ 8

1.05.04 Limiting the needle bar frame.............................................................................................. 10

1.05.05 Preliminary adjustment of the needle height....................................................................... 11

1.05.06 Needle rise, Gripper distance, Needle height and Needle guard......................................... 12

1.05.07 Needle position crosswise to sewing direction ................................................................... 14

1.05.08 Height and stroke of the bobbin case opener...................................................................... 15

1.05.09 Height of the feed wheel ..................................................................................................... 16

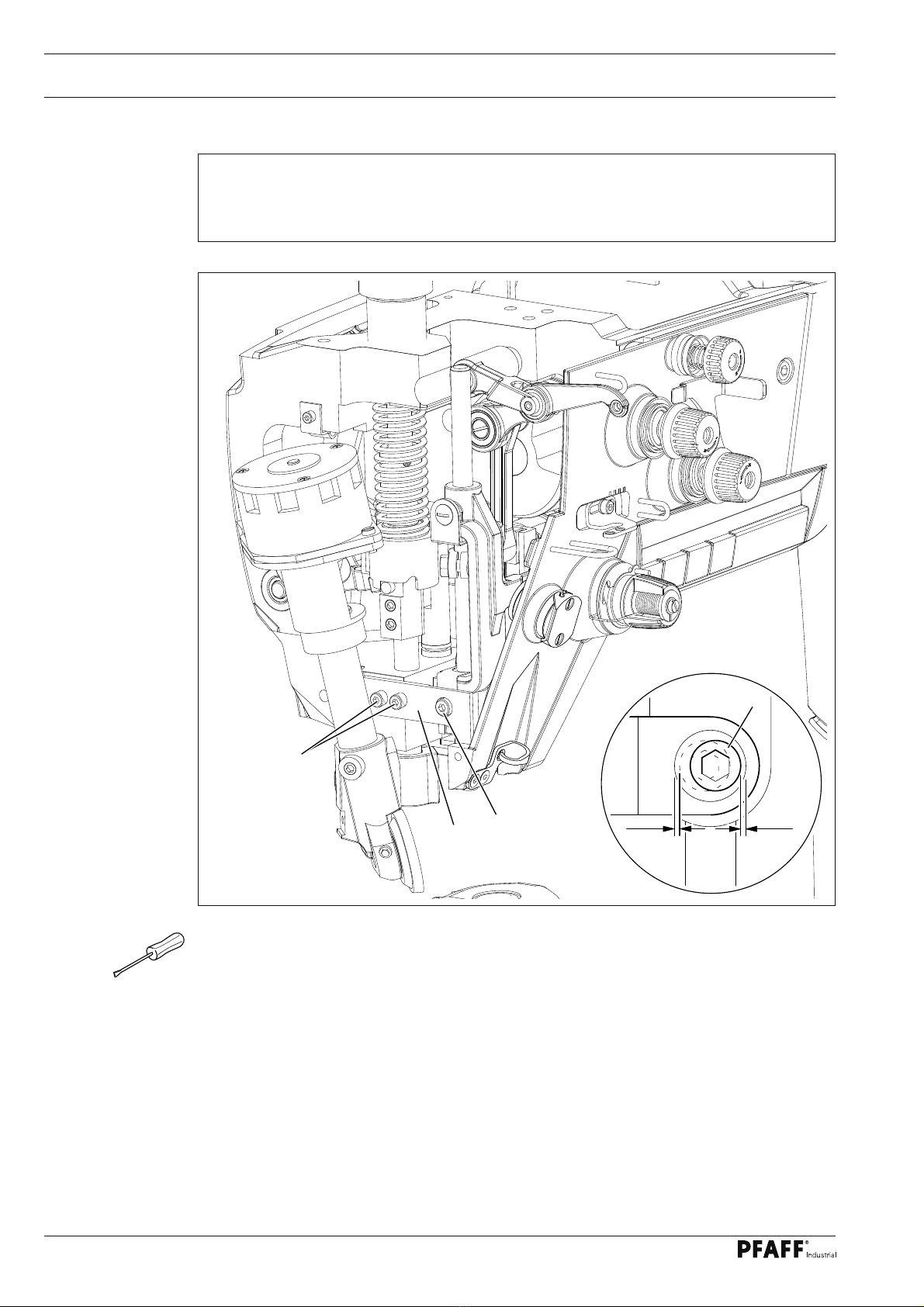

1.05.10 Roller-presser ....................................................................................................................... 17

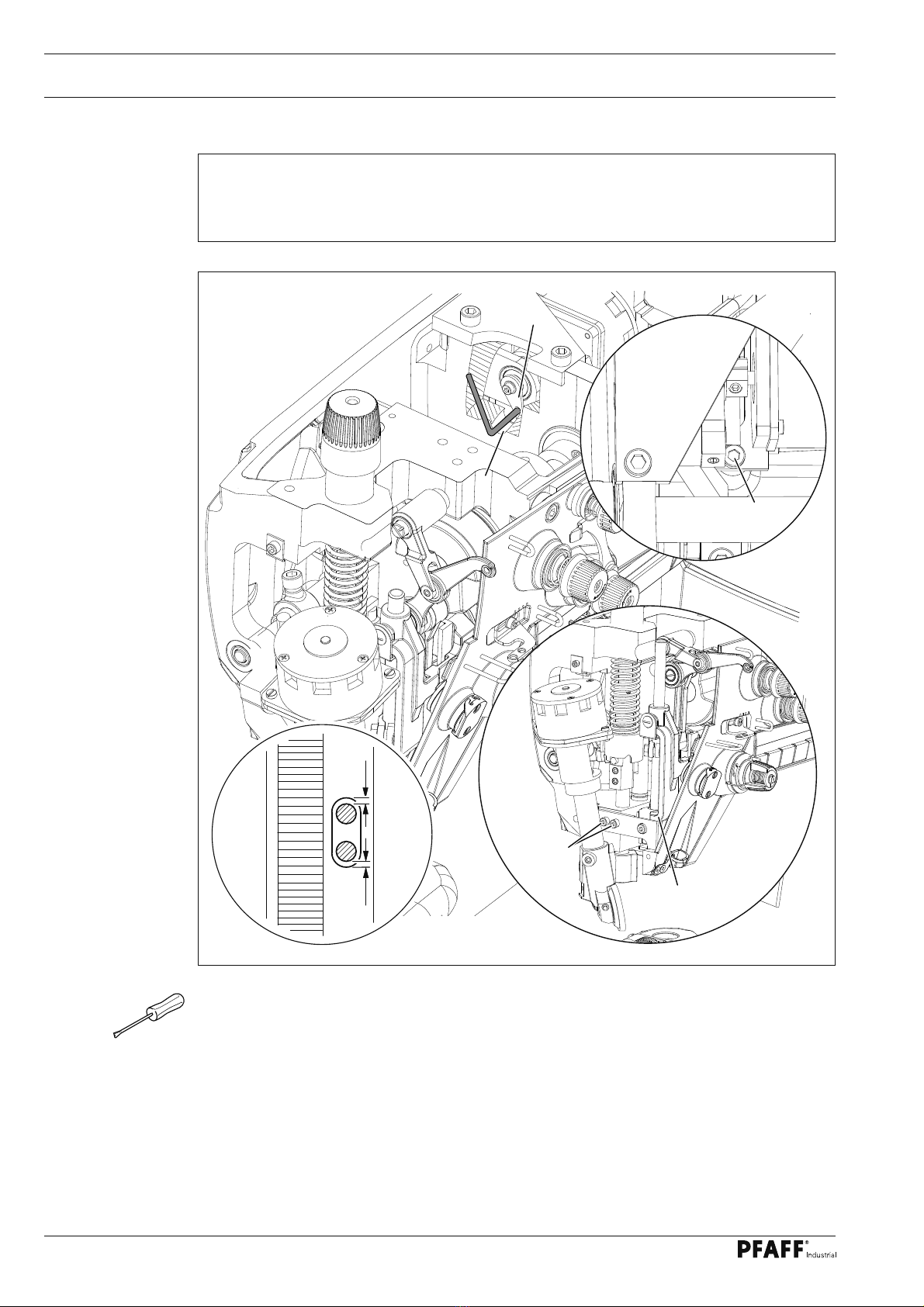

1.05.11 Clearance between roller presser and feed wheel .............................................................. 18

1.05.12 Knee lever ............................................................................................................................ 19

1.05.13 Tension release .................................................................................................................... 20

1.05.14 Thread check spring and thread regulator ............................................................................ 21

1.05.15 Bobbin winder...................................................................................................................... 22

1.05.16 Sewing foot pressure........................................................................................................... 23

1.05.18 Lubrication ........................................................................................................................... 24

1.05.19 Re-engaging the slip-clutch .................................................................................................. 25

1.06 Adjusting the thread trimmer -900/81.................................................................................. 26

1.06.01 Resting position of the roller lever / radial position of the control cam................................ 26

1.06.02 Position of the thread catcher holder ...................................................................................27

1.06.03 Distance between thread catcher and needle plate ............................................................ 28

1.06.04 Position of the thread catcher .............................................................................................. 29

1.06.05 Knife position and knife pressure......................................................................................... 30

1.06.06 Bobbin thread retaining spring............................................................................................. 31

1.06.07 Manual cutting test .............................................................................................................. 32