Ind

n

n

.................................................................................

Pa

Safety

....................................................................................................................................

1

ir

ctiv

s

..............................................................................................................................

02 General notes on safet

.........................................................................................................5

afety symbols ......................................................................................................................

04 Important points

or the user

.................................................................................................

05 O

eratin

and s

ecialist

ersonnel........................................................................................

.

1

perating personnel..............................................................................................................

5.

Specialist personnel

...............................................................................................................

06

an

er warn

n

s....................................................................................................................

roper use

............................................................................................................................

S

ecification

.....................................................................................................................

0

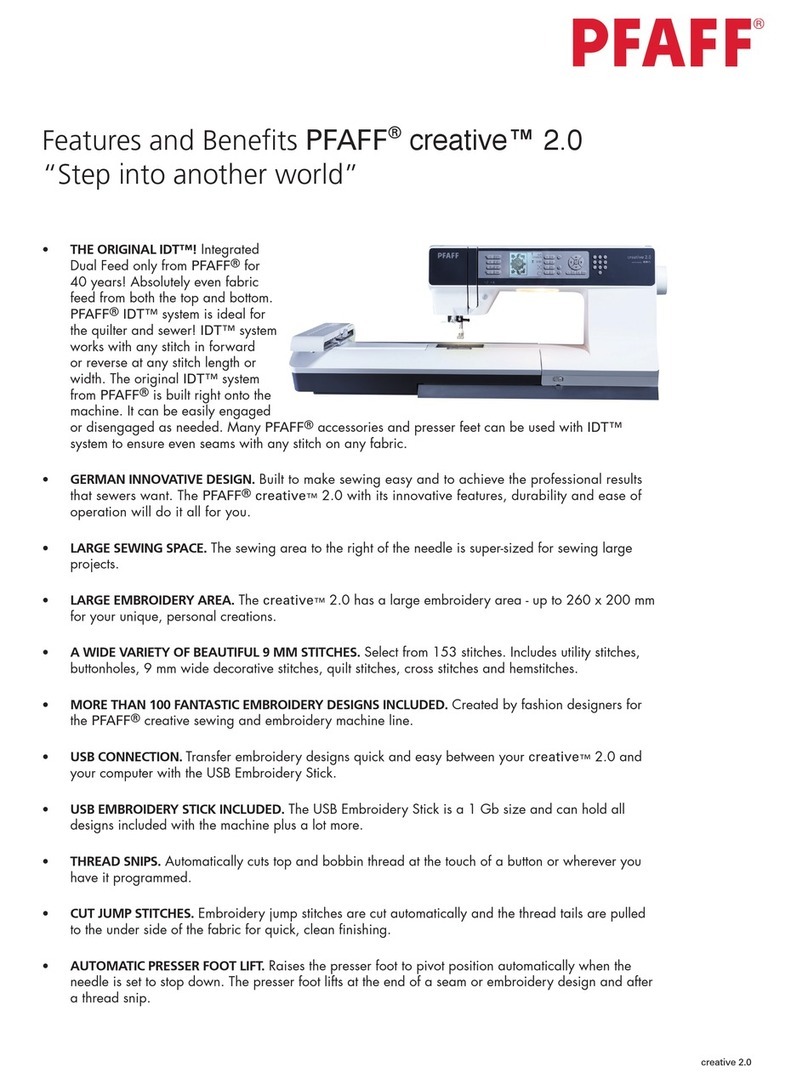

01 PFAFF 1181

PFAFF 1181-D

PFAFF 1183

PFAFF 1183-D.....................................................

2 V

r

i

n

n

l

......................................................................................................

is

osal of Machine ..........................................................................................................

Transportation, packing and storage

................................................................................

01

rans

ortat

on to customer

s

rem

ses...............................................................................13

02 Transportation inside the customer‘s premises...................................................................

03 Disposal o

packing materials

..............................................................................................

04

tora

e ................................................................................................................................13

Explanation o

symbols

.....................................................................................................

ontrols

..............................................................................................................................

1

n/

ff switch

.......................................................................................................................

02 Ke

s on the machine head (onl

for machines with -911/..).................................................15

P

....................................................................................................................................

4 Lever

or li

ting the presser

oot

...........................................................................................

05 Feed re

ulator disk / Reverse feed lever..............................................................................1

n

l

v

r............................................................................................................................

7 Thread trimmer -731

01

.......................................................................................................

0

ontrol

anel (onl

on machines with Quick-Eco drive or

uick-Pico drive

........................1

nstallation and commissioning

.......................................................................................

1

nstallation

............................................................................................................................

.

1

ust

n

t

e ta

e-to

e

t..............................................................................................

01.02 Ad

usting theV-belt tension

.................................................................................................

01.03

ount

n

t

e u

er

-

e

t

uar

........................................................................................

01.04

ount

n

t

e

ower

-

e

t

uar

.........................................................................................2

01.05 Mounting the spool holder

..................................................................................................