Contents

Contents ................................................................................. Chapter - Page

1Safety ........................................................................................................ 1 - 1

1.01 Directives ...................................................................................................................... 1 - 1

1.02 General notes on safety ................................................................................................ 1 - 1

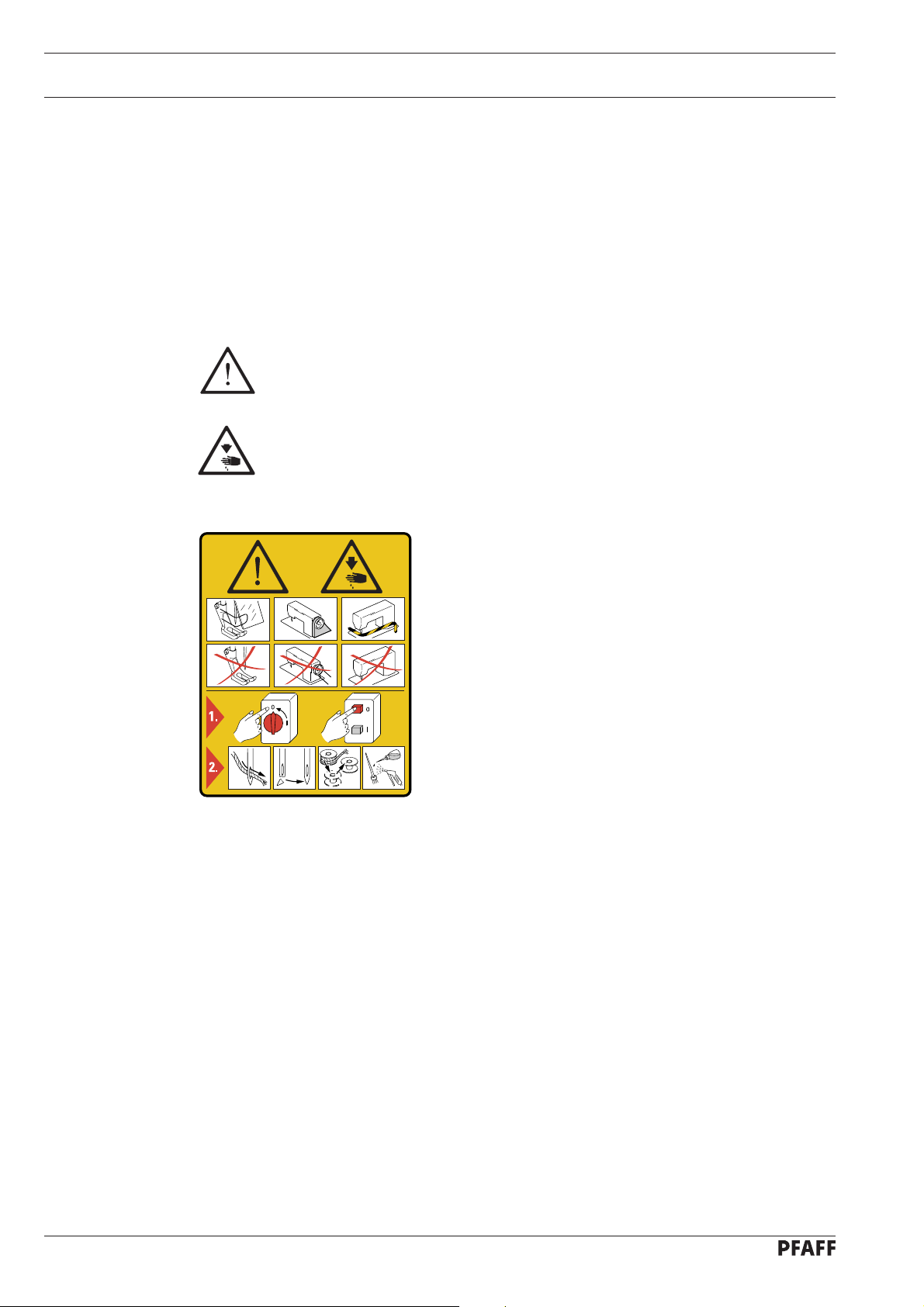

1.03 Safety symbols ............................................................................................................. 1 -2

1.04 Important points for the user ........................................................................................ 1 - 2

1.05 Operating and specialist personnel ............................................................................... 1 - 3

1.05.01 Operating personnel ...................................................................................................... 1- 3

1.05.02 Specialist personnel ......................................................................................................1- 3

1.06 Danger .......................................................................................................................... 1 - 4

2Proper use .................................................................................................. 2 - 1

3Specifications ............................................................................................. 3 - 1

4Disposal of the machine ............................................................................... 4 - 1

5Transport, packaging and storage ................................................................. 5 - 1

5.01 Transport to the customer ............................................................................................ 5 - 1

5.02 Transport within the customer’s premises ................................................................... 5 - 1

5.03 Disposal of the packaging ............................................................................................. 5 - 1

5.04 Storage ......................................................................................................................... 5 - 1

6Explanation of the symbols .......................................................................... 6 - 1

7Controls ....................................................................................................................... 7- 1

7.01 Adjusting the stitch length ............................................................................................ 7 - 1

7.02 Adjusting the top feed stroke on the PFAFF 5625-657/01 ............................................. 7 - 1

7.03 Adjusting the top feed stroke on the PFAFF 5625-657/02 ............................................. 7 - 2

7.04 Lifting the presser foot .................................................................................................. 7 - 2

7.05 Key for fixing the presser foot ....................................................................................... 7 - 3

8Installation and commissioning ................................................................................. 8 - 1

8.01 Installation ..................................................................................................................... 8 - 1

8.02 Commissioning ............................................................................................................. 8 - 1

9Setting up .................................................................................................................... 9 -1

9.01 Inserting the needle ...................................................................................................... 9 - 1

9.02 Threading the machine / adjusting the thread tension ................................................... 9 - 2

10 Care and Maintenance .............................................................................................. 10 - 1

10.01 Cleaning the looper compartment ............................................................................... 10 - 1

10.02 Checking the oil level / filling in oil ............................................................................... 10 - 2

10.03 Checking the oil level in the oil tank for the needle head parts / filling in oil ................ 10 - 3