2 104 72 63-26

Contents

Foreword .......................................................................................................................................3

Replacing the External Parts.........................................................................................................4

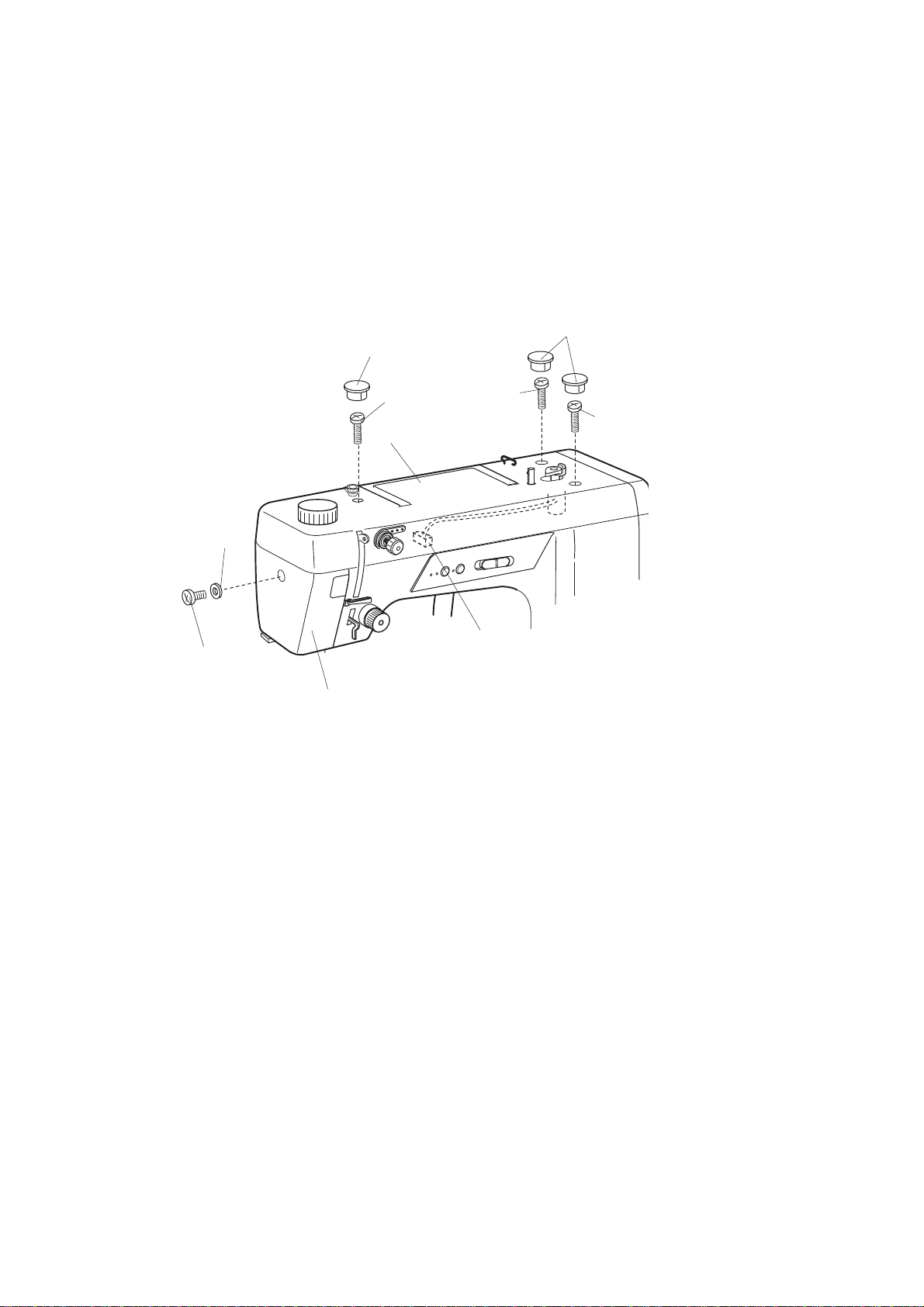

Face Plate .....................................................................................................................................4

Top Cover......................................................................................................................................4

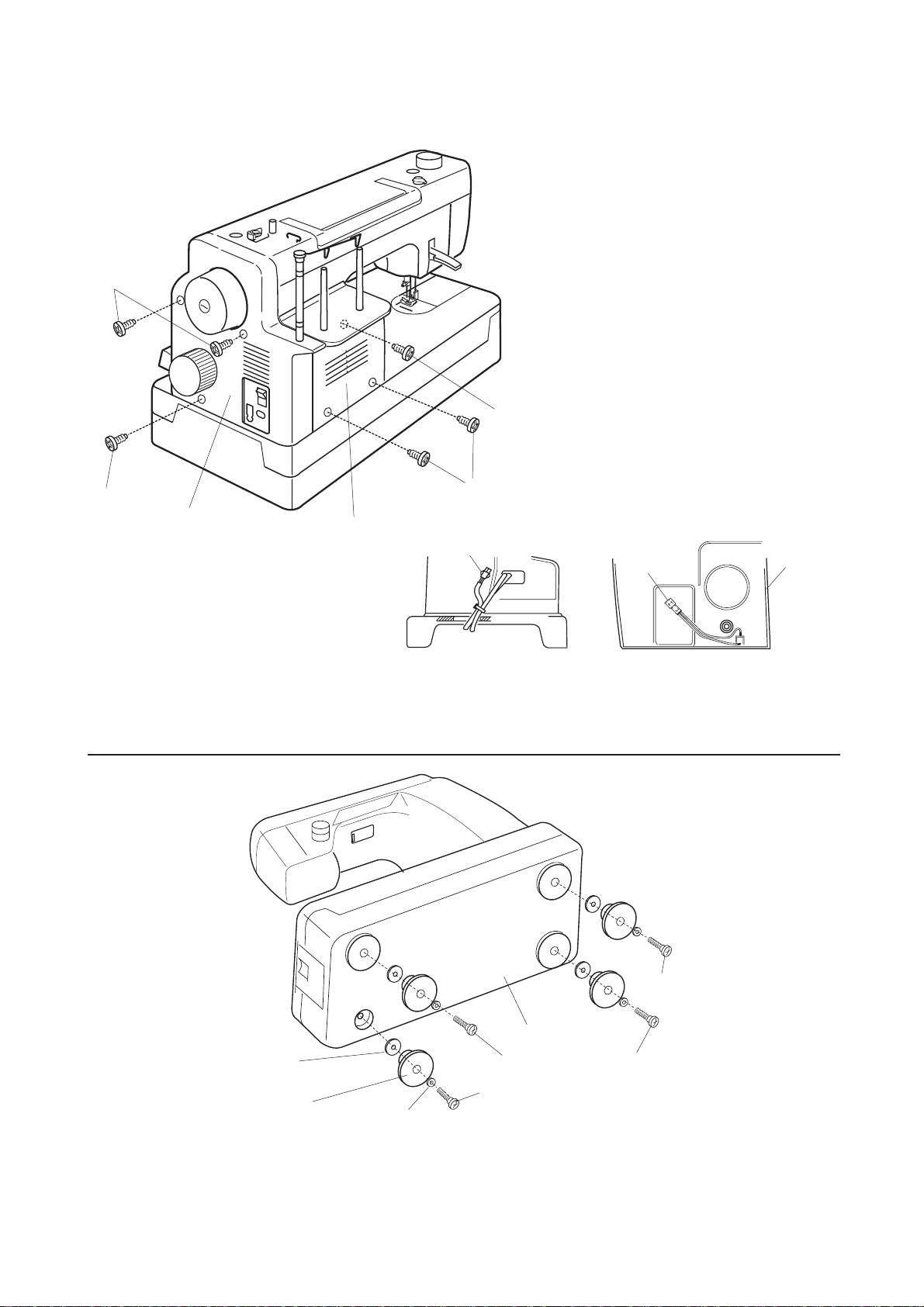

Belt Cover......................................................................................................................................5

Motor Cover...................................................................................................................................5

Base ..............................................................................................................................................5

Adjustment of the needle bar height..............................................................................................6

Adjustment of the timing of the hook in relation to the needle.......................................................8

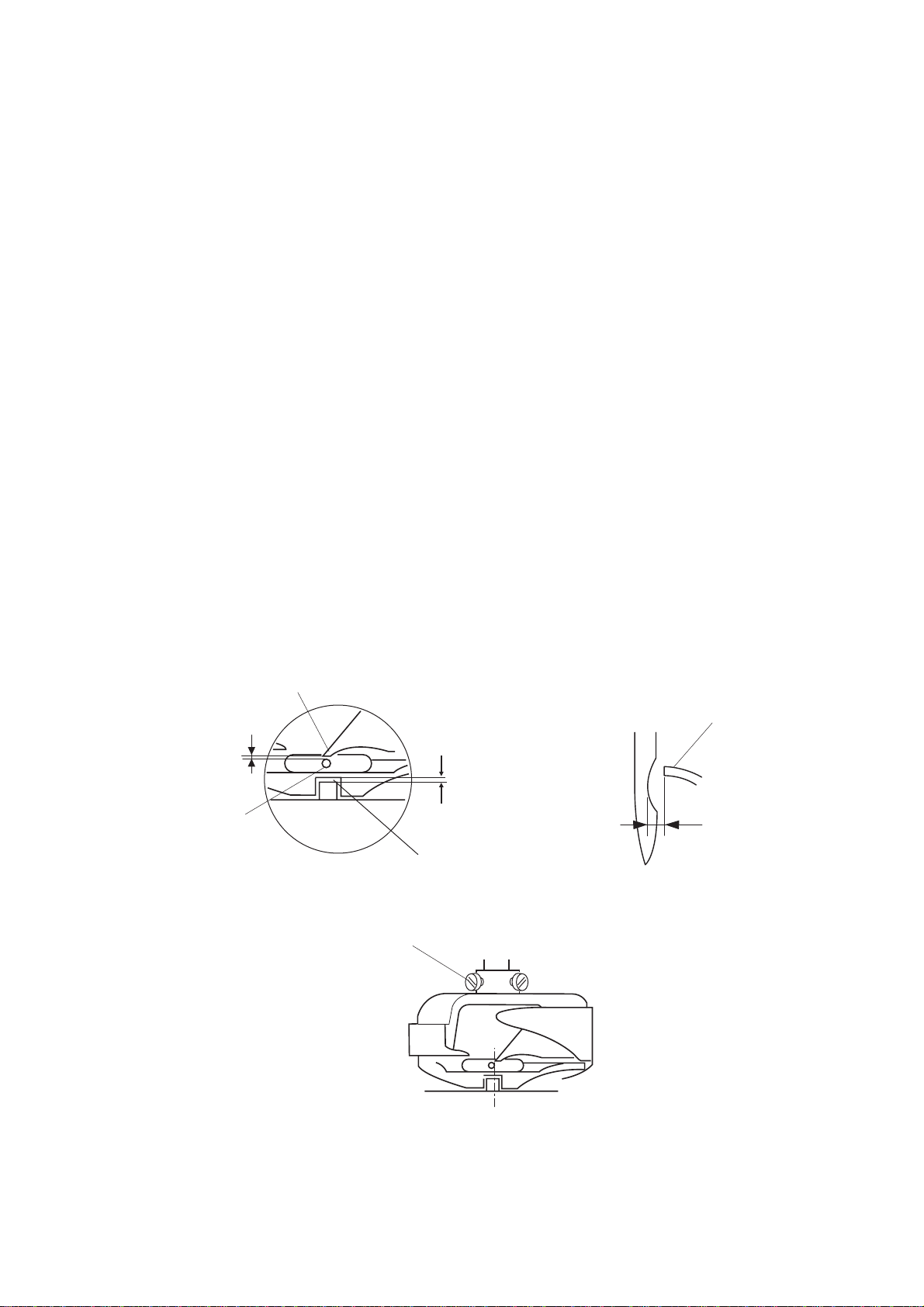

Adjustment of the clearance between needle and point of hook...................................................9

Adjustment of bobbin case position finger...................................................................................10

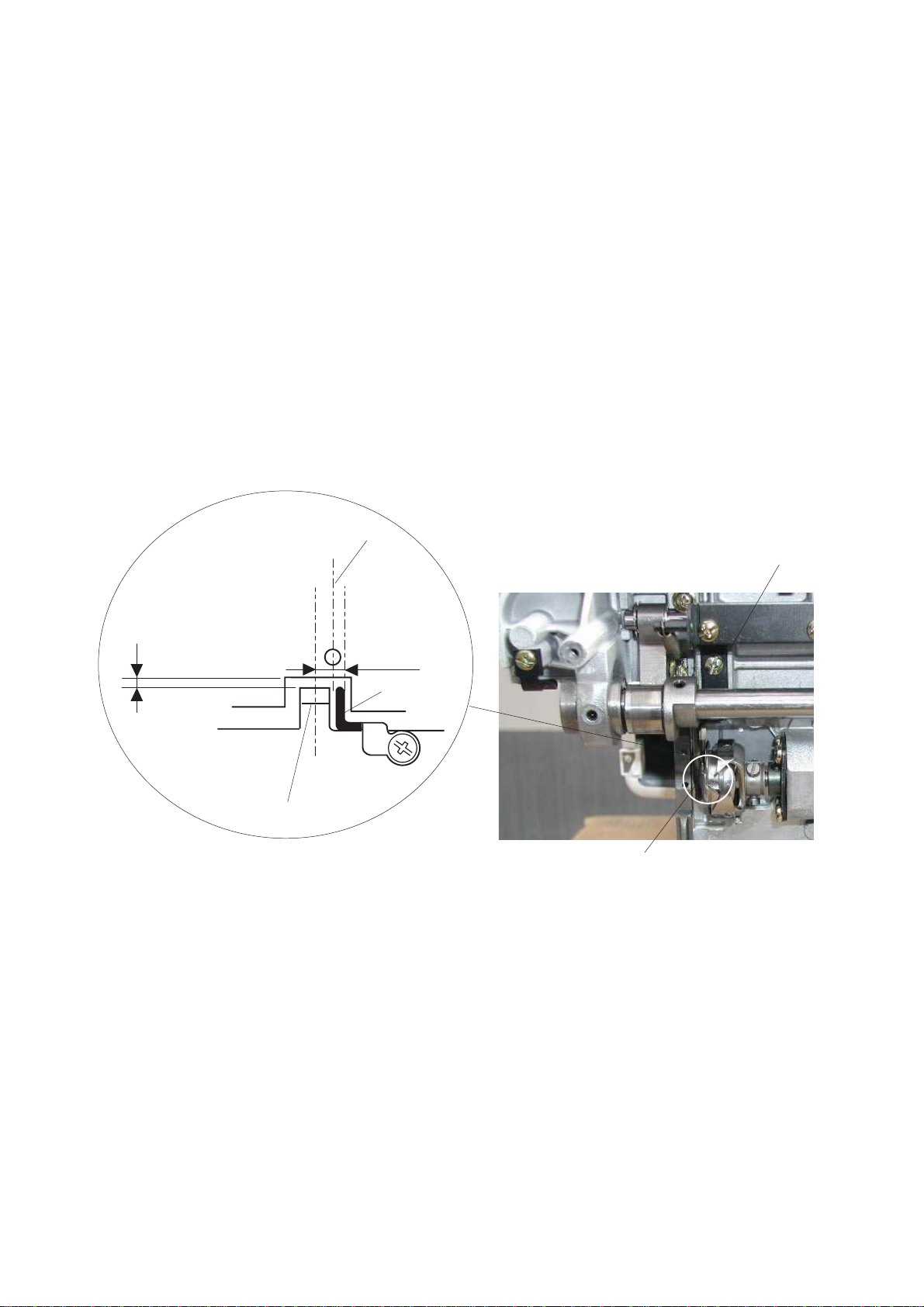

Adjustment of the presser bar height and alignment...................................................................11

Adjustment of the knee lifter lever...............................................................................................12

Adjustment of the Feed Cam Timing...........................................................................................13

Adjustment of the Feed Lifting Cam Timing................................................................................14

Adjustment of the parallelism and lengthwise movement of the Feed Dog ................................16

Adjustment of synchronizer.........................................................................................................17

Adjustment of bobbin thread tension...........................................................................................18

Adjustment of pre-tension dial.....................................................................................................18

Adjustment of thread check spring stroke ...................................................................................19

Replace and Adjust the Thread Guide Plate ...............................................................................20

Adjustment of the Fixed Cutter Knife...........................................................................................21

Adjustment of the needle to cutter cam timing............................................................................24

Adjustment of the thread drawing lever.......................................................................................25

Adjustment of the auto tension release.......................................................................................26

Thread Cutter Troubleshooting....................................................................................................27

Adjustment of bobbin winder stopper..........................................................................................28

Replacing the Electronic Components ........................................................................................29

Location of the Electronic Components.......................................................................................29

Location of the Connectors..........................................................................................................29

Internal Wiring .............................................................................................................................30

Replace the Circuit Board-A........................................................................................................31

Replace the Circuit Board-F and Slide Volume...........................................................................32

Replace the Light Bulb ................................................................................................................32

Replace the motor and Adjust the motor belt tension..................................................................34

Replace the transformer..............................................................................................................35

Replace the Machine Socket.......................................................................................................35