Pfaff coverlock 4872 User manual

Other Pfaff Sewing Machine manuals

Pfaff

Pfaff expression line User manual

Pfaff

Pfaff hobbymatic 953 User manual

Pfaff

Pfaff 5704 User manual

Pfaff

Pfaff ClassicStyle 1525 User manual

Pfaff

Pfaff 3117 User manual

Pfaff

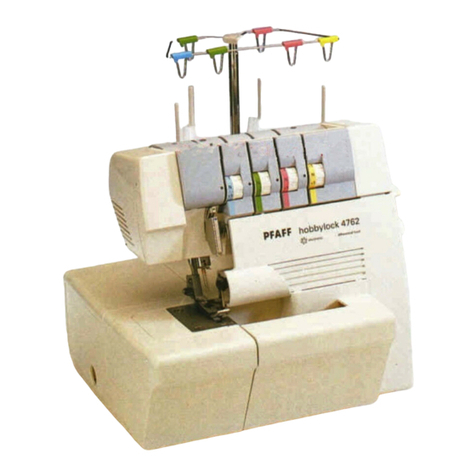

Pfaff hobbylock 4762 User manual

Pfaff

Pfaff Ccreative 2.0 User manual

Pfaff

Pfaff C1100 Pro User manual

Pfaff

Pfaff COVERLOCK 3.0 - User manual

Pfaff

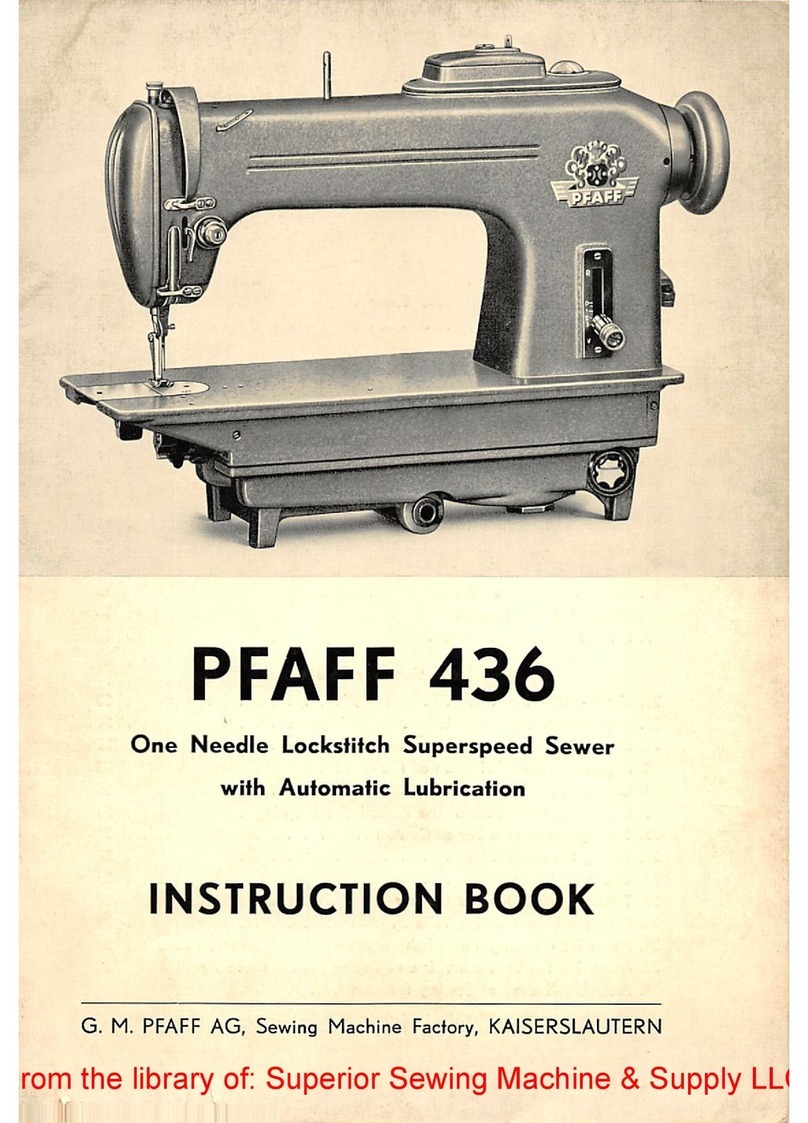

Pfaff 436 User manual

Pfaff

Pfaff 3582-2/01 User manual

Pfaff

Pfaff expression 2026 User manual

Pfaff

Pfaff 1529 User manual

Pfaff

Pfaff 3806-12/22 Guide

Pfaff

Pfaff 1571 User manual

Pfaff

Pfaff 3566-2/02 User manual

Pfaff

Pfaff creative 7570 User manual

Pfaff

Pfaff Creative Vision User manual

Pfaff

Pfaff 3827-4/33 User manual

Pfaff

Pfaff Series 580 Owner's manual