2 BG 5034 BEN (2017-01) IMR420_430.oi

Meaning of the sticker "Calibration", 12).

In all communications with Pfeiffer Vacuum, please specify the information on the

product nameplate.

Specimen nameplate

This document applies to products with part numbers

PT T07 359 900 (IMR 420, Bayard-Alpert Gauge)

PT T08 359 900 (IMR 430, Extractor Gauge)

PT 548 332 -T (Gauge head cable, 3 m)

PT 548 333 -T (Gauge head cable, 5 m)

PT 548 334 -T (Gauge head cable, 10 m)

PT 548 338 -T (Gauge head cable, 50 m)

PT 548 342 -T (Gauge head cable, temperature resistant 200 °C, 3 m)

PT 548 343 -T (Gauge head cable, temperature resistant 200 °C, 5 m)

PT 548 344 -T (Gauge head cable, temperature resistant 200 °C, 10 m)

PT 548 348 -T (Gauge head cable, temperature resistant 200 °C, 50 m)

The part number (No:) can be taken from the product nameplate.

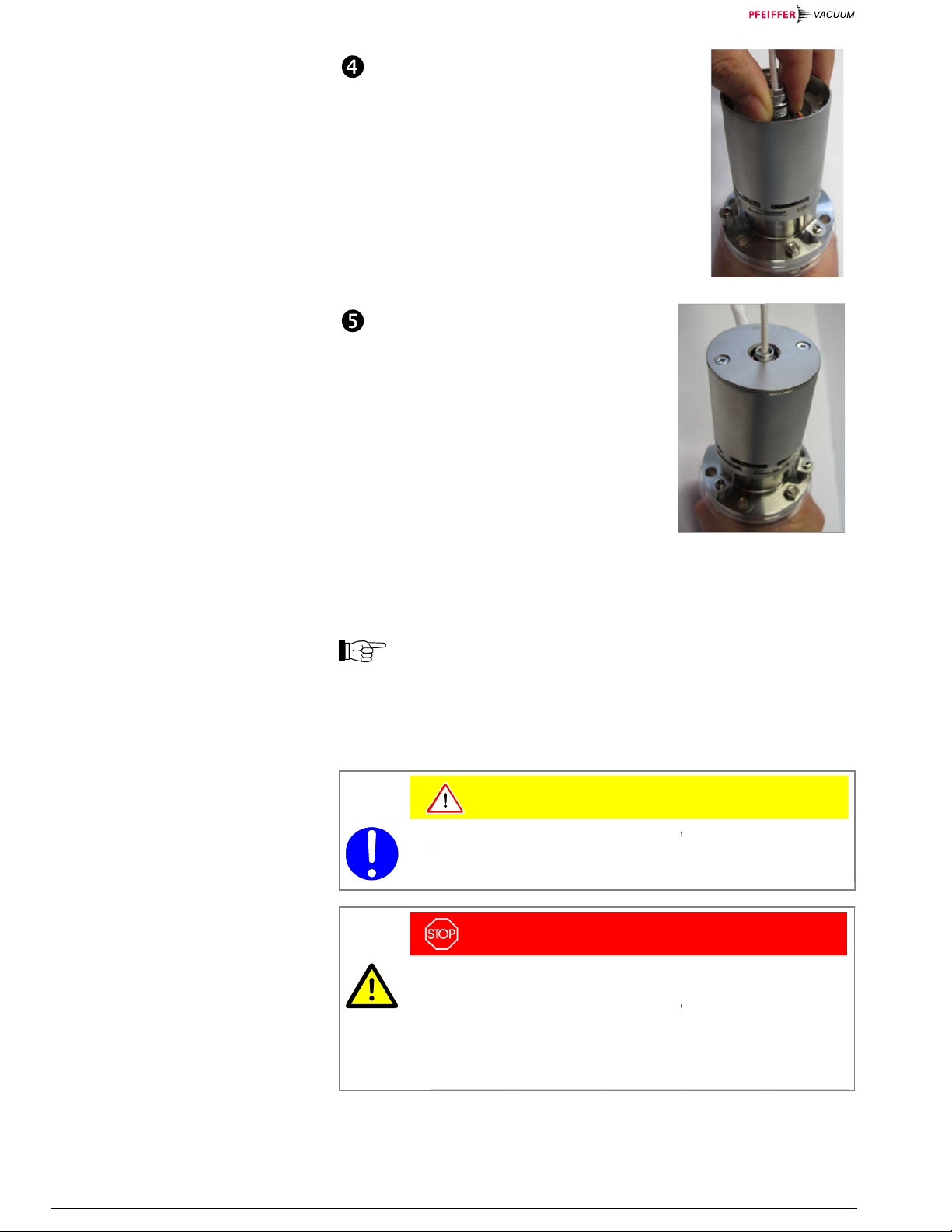

If not indicated otherwise in the legends, the illustrations in this document corre-

spond to the IMR 420 Bayard-Alpert gauge. They apply to the IMR 430, extractor

gauge by analogy.

We reserve the right to make technical changes without prior notice.

All dimensions in mm.

The references to diagrams, e.g. (2/3), consist of the fig. no. and the item no. in

that order.

The IMR 420 is a Bayard-Alpert measurement system and the IMR 430 is an ex-

tractor measurement system for connection to an IMG 400 operating unit. Opera-

tion of these passive sensors is based on the hot cathode ionisation effect.

The temperature resistant gauge head cable must not be exposed to a tempera-

ture exceeding 200 °C max. (250 °C at the flange of the sensor).

The IMR 420 and IMR 430 gauges may only be used for the measurement of total

pressures in vacuum systems and this only in connection with the IMG 400 opera-

ting unit.

Sticker

Product Identification

Validity

Description

Intended Use