2BG 5036 BEN / A (2016-07) PS115_SC110.oi

In all communications with Pfeiffer Vacuum, please specify the information on the

product nameplate. For convenient reference copy that information into the space

provided below.

This document applies to products with part numbers

PT R02 110 (PS 115 Pressure Switch)

PT 120 171 -T (Differential Pressure Adapter)

PT 120 172 (Pressure switch adjustment)

PT R02 111 (SV 110 Switching amplifier)

The part number (No:) can be taken from the product nameplate.

We reserve the right to make technical changes without prior notice.

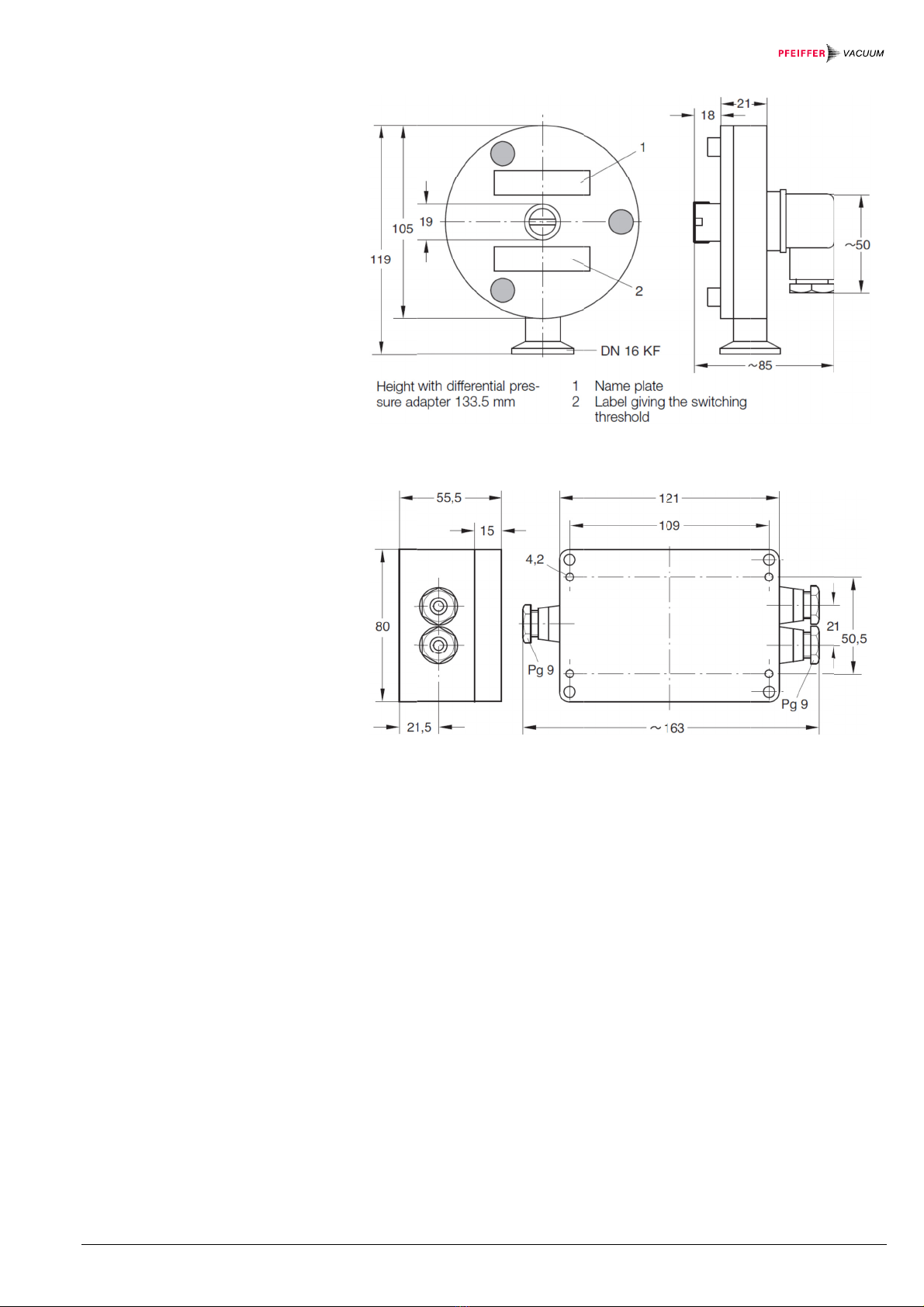

All dimensions in mm.

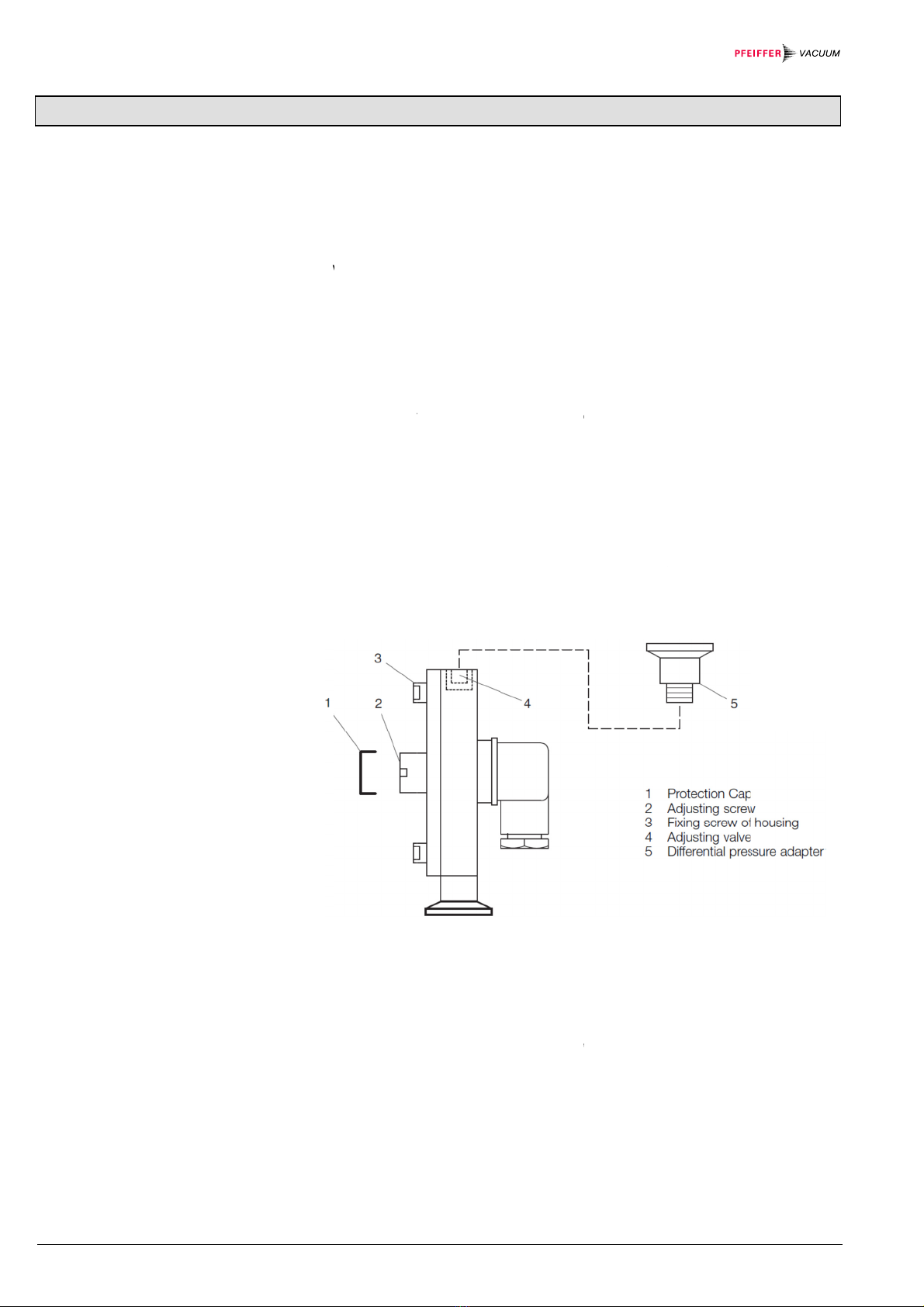

The references to diagrams, e.g. (4/5), consist of the fig. no. and the item no. in

that order.

The pressure switch PS 115 in connection with the switching amplifier SV 110 is

used to produce pressure dependent signals and for the control of valves and

pumps.

The pressure switch PS 115 can also be used as a differential pressure switch.

Unpack the pressure switch and the switching amplifier immediately after delivery,

even if they are to be put into operation at a later date.

Before doing so, examine the shipping container for any external damage.

Then completely remove the packaging materials.

The shipping container and packaging materials must be kept in the event of

complaints about damage.

Check for completeness.

Carefully examine the pressure switch and the switching amplifier visually.

If any damage is discovered, report it immediately to the forwarding agent and in-

surer. If the damaged part has to be replaced, please get in touch with the orders

department.

The PS 115 is a diaphragm absolute pressure switch. He can also be used as a

differential pressure switch.

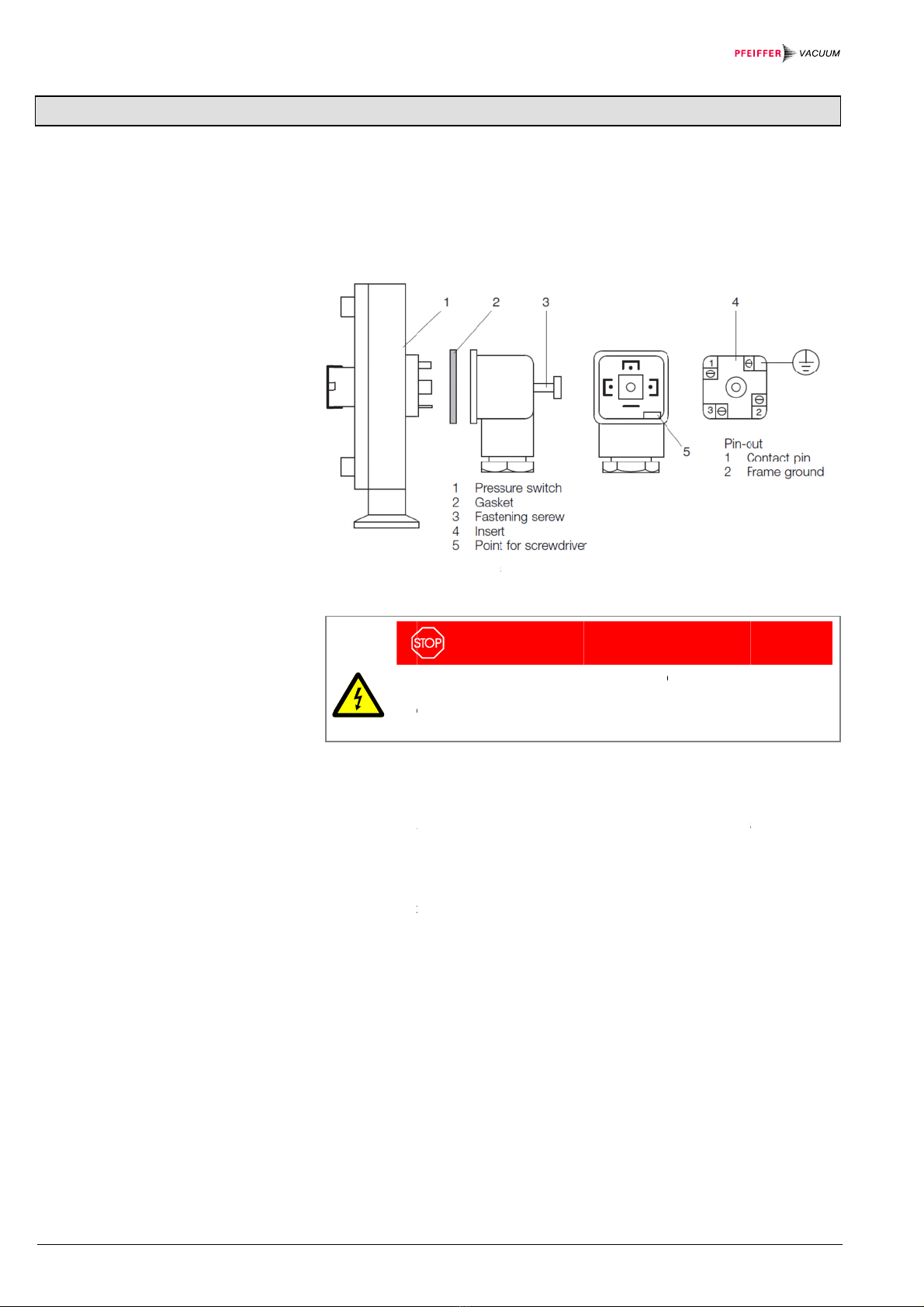

Within both pressure switches there is a sensing chamber (1/2) and a reference

chamber (1/5) separated by a highly sensitive sealed diaphragm made of stainless

steel (1/3). A pin (1/6) in the reference chamber (1/5) is led to the outside and

insulated (1/7). The ground connected diaphragm acts as the opposite contact.

This contact configuration is so designed that the diaphragm contacts the pin when

it is unstressed, i. e. with equal pressure in sensing and reference chamber.

Product Identification

Validity

Description

Unpacking and Checking

Design and Function