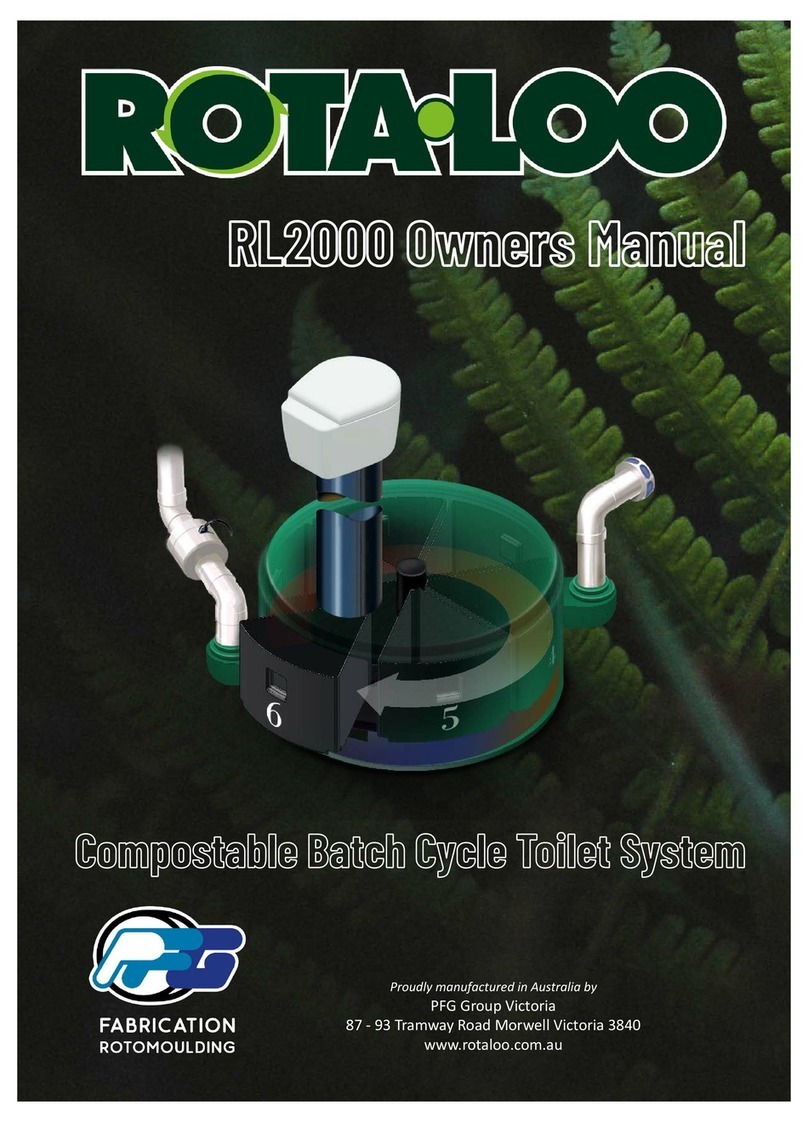

CONGRATULATIONS AND THANK YOU FOR PURCHASING YOUR NEW ROTA LOO

The reasons for purchasing a Rota-Loo may be varied. It could be to conserve water, the pursuit of a more

sustainable life style, or that mains sewer is not available. Your decision will help towards conserving

water, reduce waste processing costs and contribute to a more sustainable future.

The rst portable composting toilet came into Australia from Sweden in the late 1970’s. From this idea the

Rota-Loo was born, and has been developed and improved over the years to become one of the best

Waterless Composting Toilet (WCT) systems in the world and have been successfully installed and operated

in thousands of places throughout Australia, New Zealand and further aeld.

Today, Waterless Composting Toilets are becoming more widely accepted and other products have

appeared on the market. With Rota-Loos installed decades ago still operating well and owners

recommending them to others, the Rota-Loo remains the simplest, most efcient and cost effective WCT

available.

We hope the Rota-Loo fullls your expectations and that it may even ignite a hidden passion to live a

sustainable lifestyle and pass on the message. If you have difculty in installing or maintaining your

Rota-Loo, please get in touch with your supplier or through our website at www.rotaloo.com.au.

OceanaMark

OPMK30059

AS/NZS 1546.2

PFG Group Victoria Pty Ltd

is a Quality Assured

company certied

as compliant to

ISO9001:2015

AS/NZS 1546.2:2008 is the Standard that sets out the

requirements for the design and performance of Waterless

Composting Toilets to assure of safe, effective and efcient

operation. Authorities regulating the installation of Waterless

Composting Toilets (local Councils etc) require Certication to the

Standard to approve the installation of a system like Rota-Loo

CONTENTS

Introduction..............................................................................................................................................................page2

The Composting Process....................................................................................................................................page 2

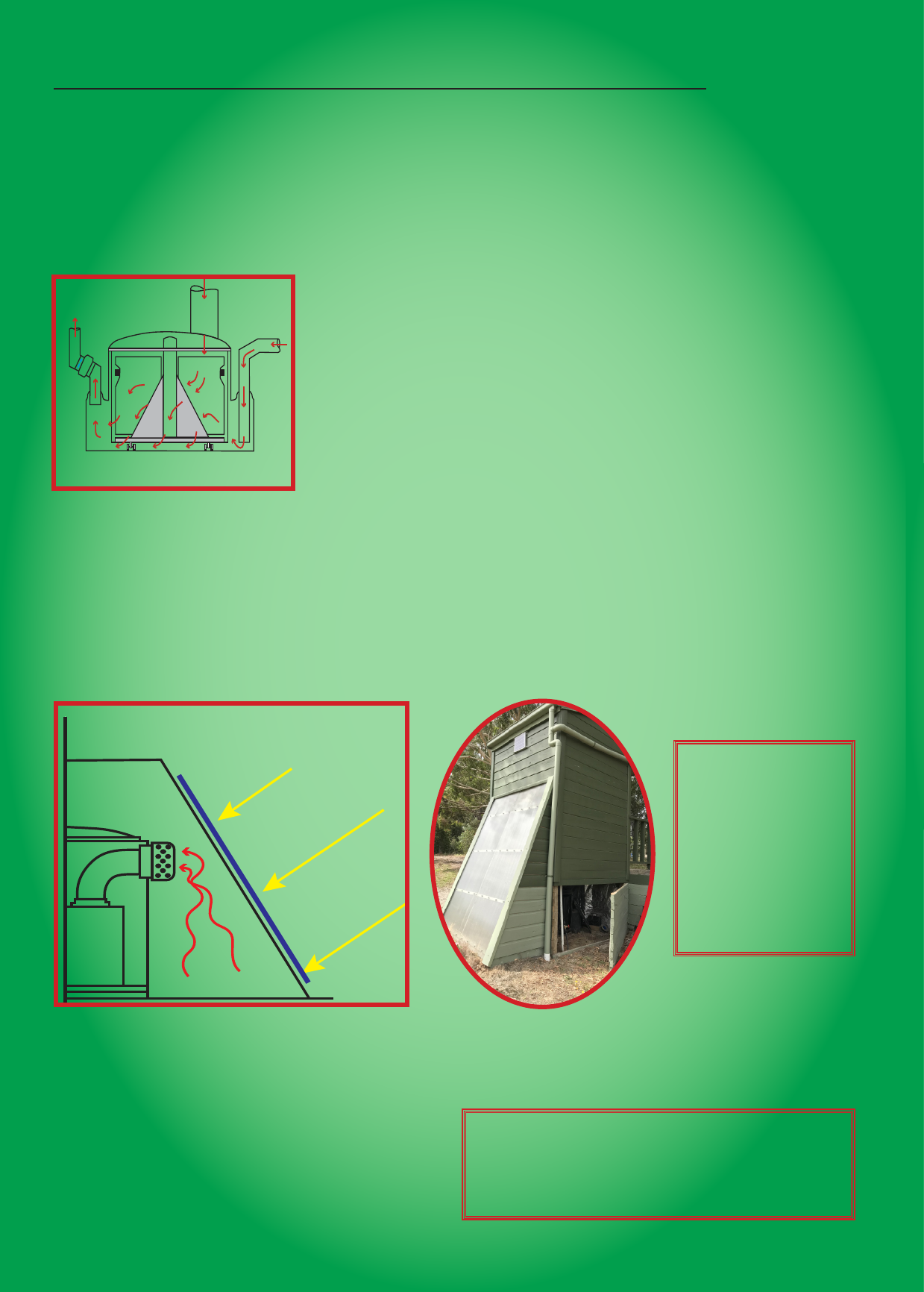

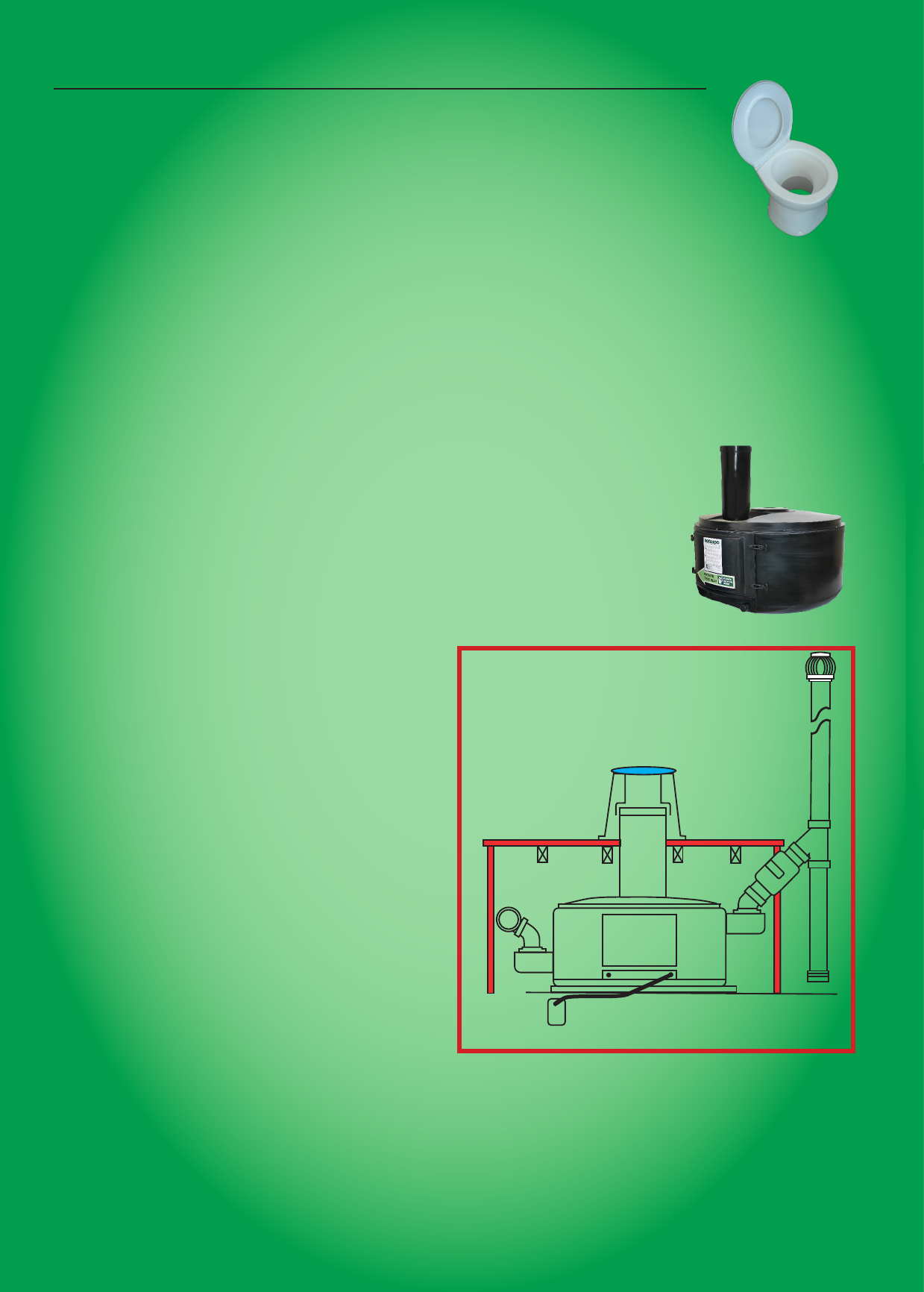

How Rota-Loo Works..........................................................................................................................................page 3

A Quick Guide..........................................................................................................................................................page 4

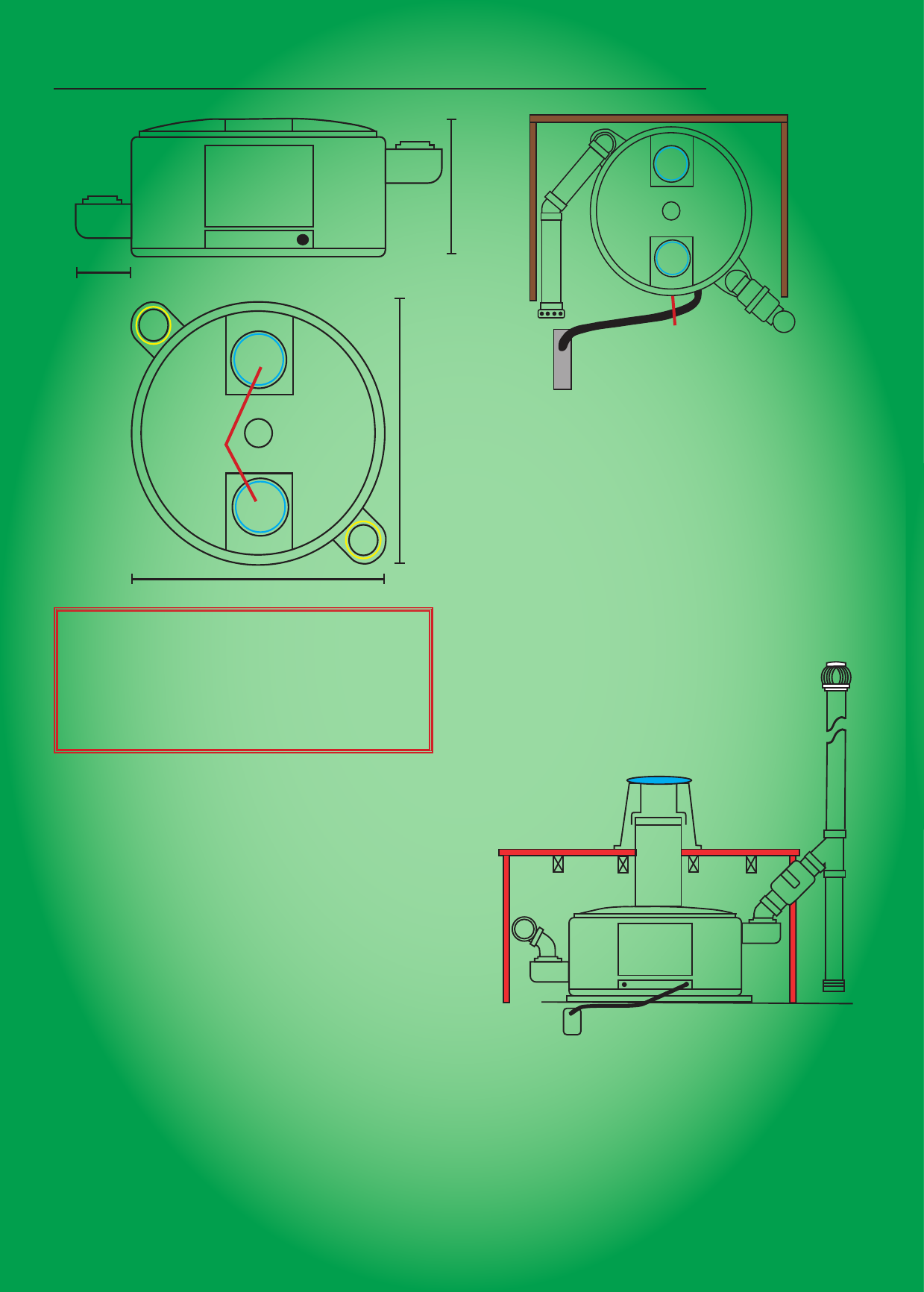

Installation Planning-Space Required..........................................................................................................page4

Installation Planning - Toilet Pedestal Location.........................................................................................page 5

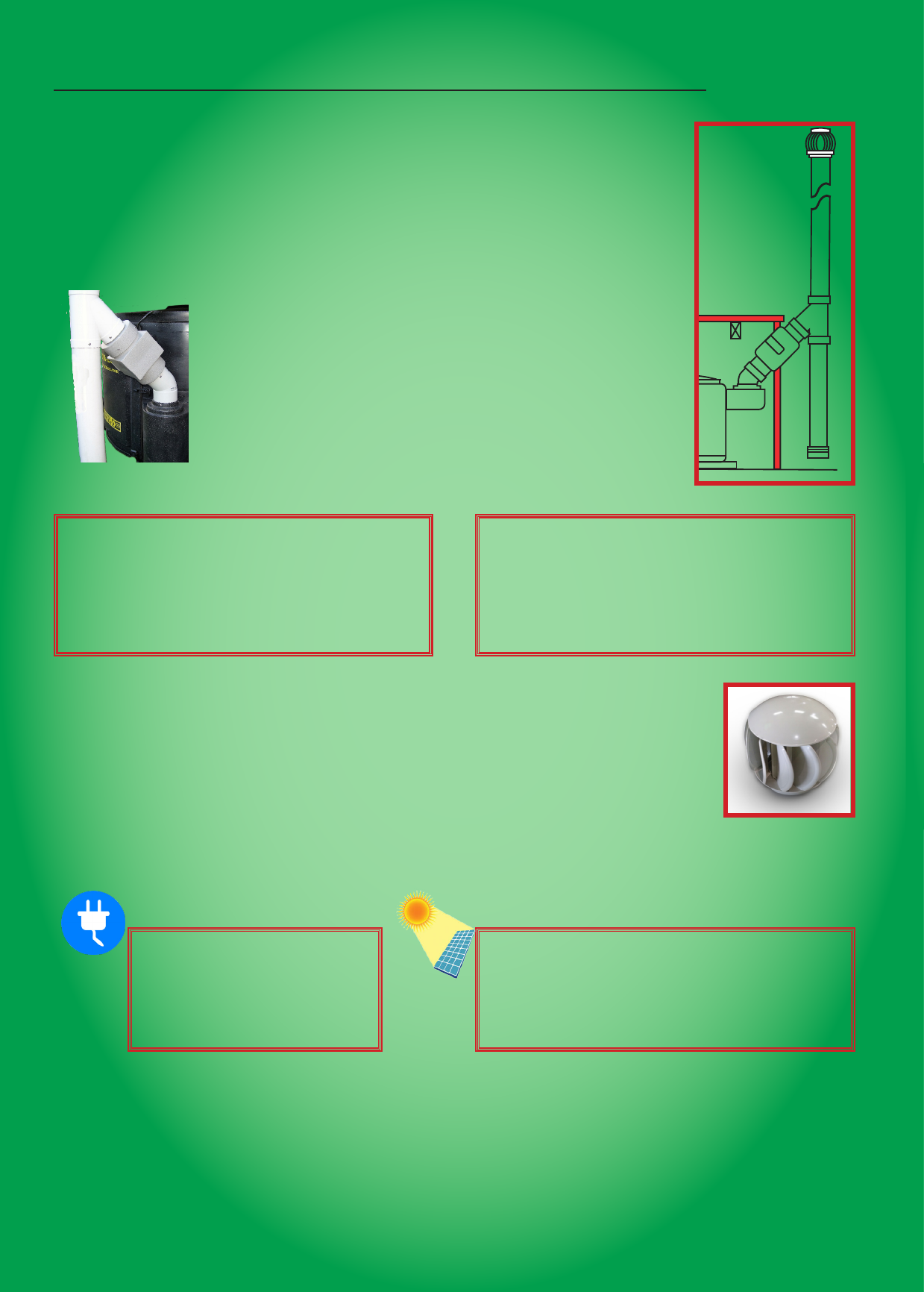

Installation Planning - Structural Issues, Vent System, Excess Liquid................................................page 6

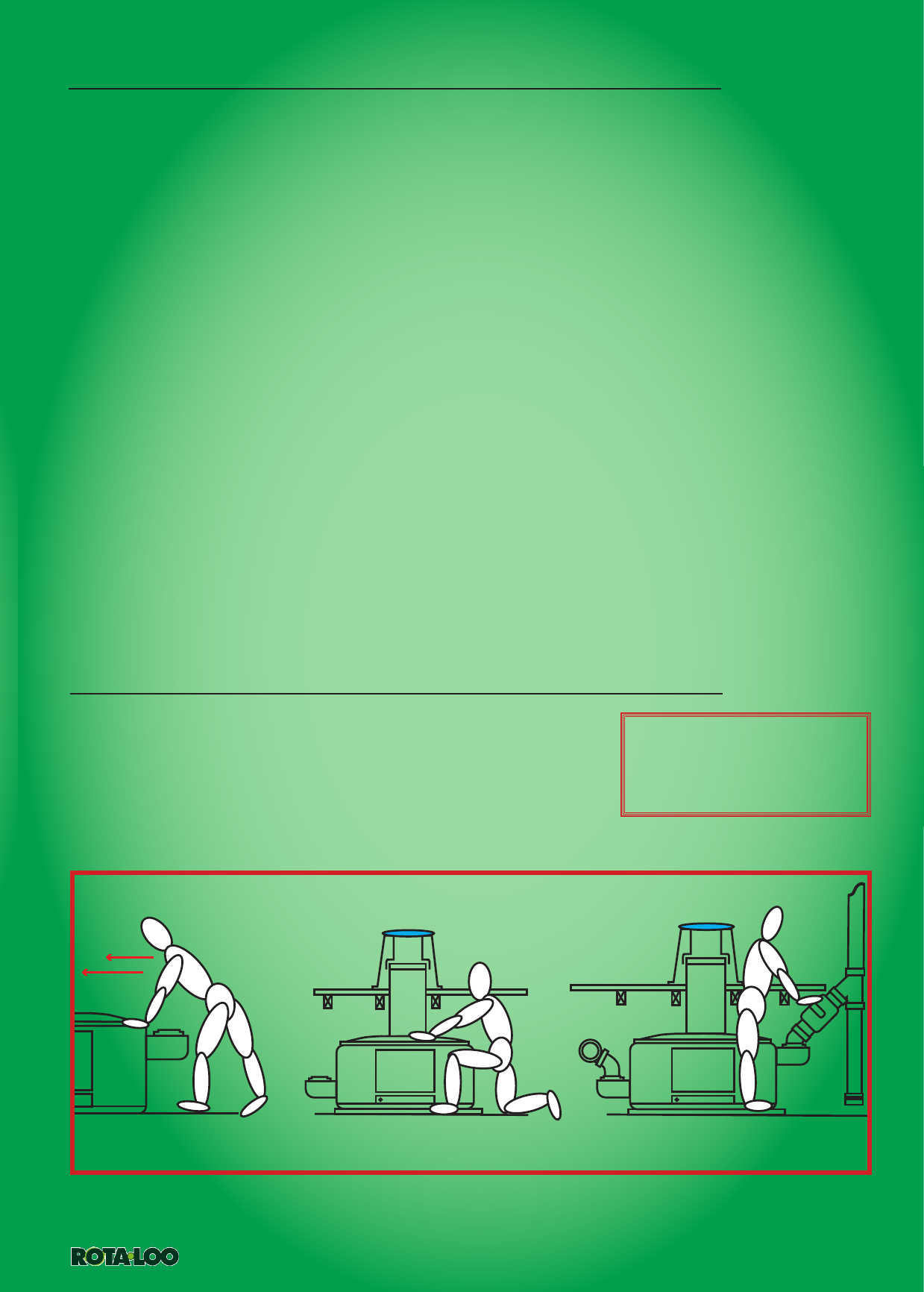

Installation - Locate Rota-Loo, Prepare Floor..............................................................................................page 7

Installation - Attach Pods, Final Location, Attach Inlet Piping................................................................page 8

Installation - Attach Fan & Outlet Piping, Turbo Vent, Fan, Electrical Connection, Insulation.........page 9

Installation - Waste Chute & Pedestal, Final Checks................................................................................page 10

Operation Overview...........................................................................................................................................page 11

Operation - Start, Bin Filling............................................................................................................................page 11

Operation - What to put in, What NOT to put in, Cleaning Pedestal.................................................page 12

Operation - Bin Rotation, Keeping Record.................................................................................................page 13

PeriodicMaintenance- Salt Build up, Fan....................................................................................................page 14

Trouble Shooting...............................................................................................................................................page 15

Risk Assessment - Inspection, Storage, Access, Quality....................................................................page 17

Risk - Transfer of Ownership, No Bulking Material, Carousel Not Turned, Too Hot..................page 18

Risk - Too Cold, Too Humid, Is Removed Early, Poor Drainage, Flooding.....................................page 19

Risk - Decommissioning.................................................................................................................................page 20

Warranty..............................................................................................................................................................page 21

Appendix - Checklist, Kit Parts List, Tools List.......................................................................................Page 22