15710-0004 | Rev C | 2018-04-01 | e-mail psd@pow.com Section 2 | 1

Section 2 | General Information

www.pflow.com

P 41 4 3 5 2 9 0 0 0

F 41 4 3 5 2 9 0 0 2

6 7 2 0 N. Te uto nia Ave .

Milwauke e , WI 5 3 2 0 9

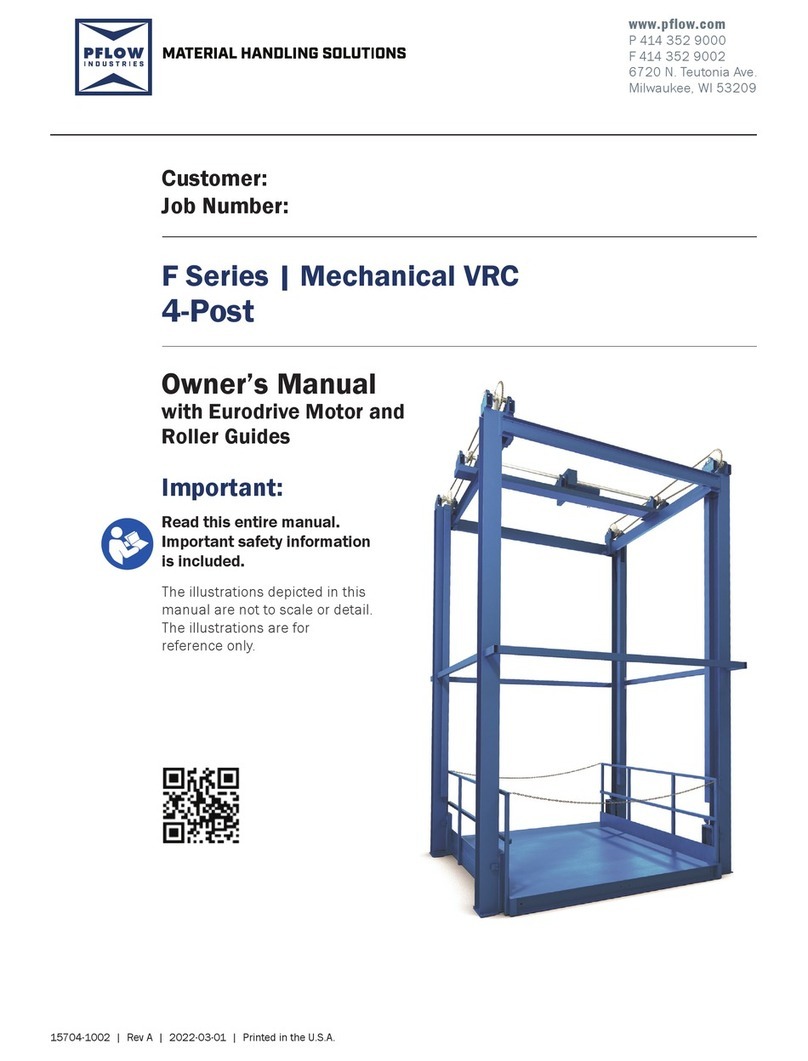

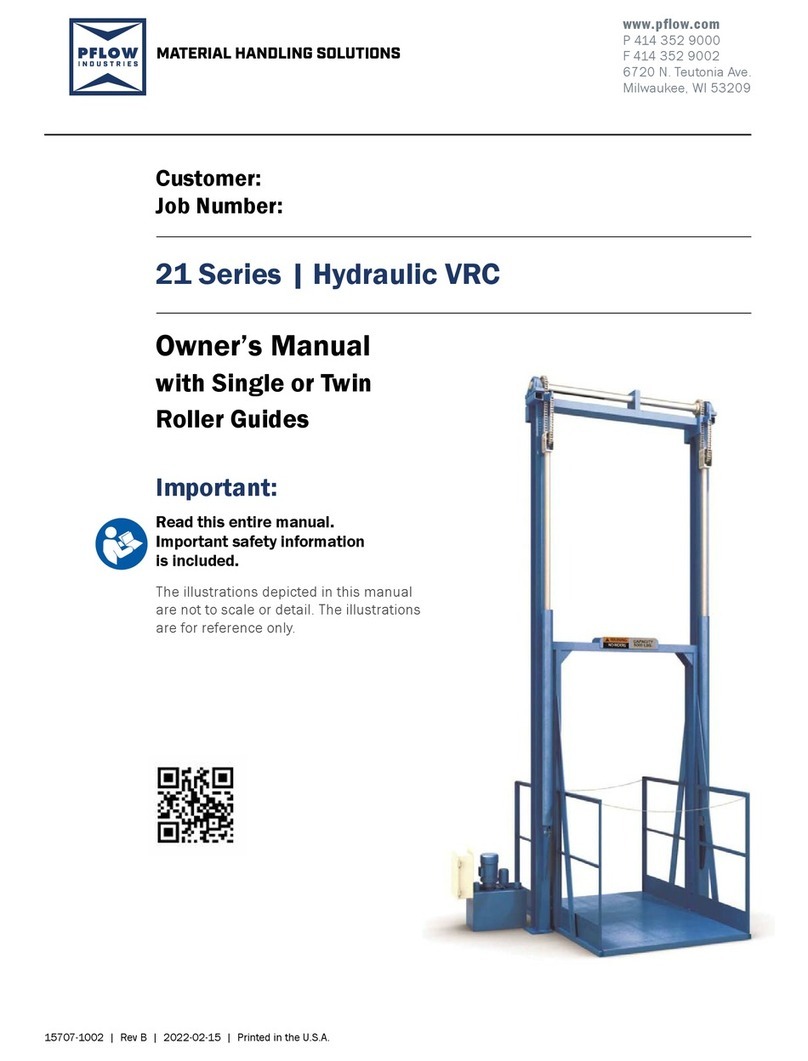

This manual provides information about the PFlow Industries, Inc. custom designed

Vertical Reciprocating Conveyor (VRC). As the nations’ leading manufacturer of

vertical material handling equipment, PFlow Industries, Inc. is condent that this

new VRC will provide many years of reliable service.

The VRC provides a safe and simple means of moving material from one level to

another. The simplicity of design and few moving components ensure a trouble-free,

long life, with low maintenance and little downtime.

This VRC is designed for the movement of materials only, up to the VRC’s rated capacity,

from one level to the next. Do not allow anyone to ride on the VRC. VRCs are not

elevators, and are specically excluded within the scope of the ASMEA17.1 Safety

Code for Elevators and Escalators. VRCs are included in ASMEB20.1 Safety Standard

for Conveyors and Related Equipment, which is incorporated by reference into OSHA

29 CFR 1910. A copy of the ASME B20.1 standard can be purchased at

www.asme.org and other sources. PFlow Industries, Inc. recommends that this

standard be referenced for appropriate installation, maintenance, inspection,

and operation in relation to hazards. All electrical designs and components are in

accordance with National Electric Code (NEC) requirements. Local codes may

require initial inspection of the installation and periodic inspection and testing of the

unit. Contact PFlow Industries, Inc. for more information in the event an inspection

is required.

The information and illustrations in this manual are intended only as an aid to understanding

the VRCs general installation. The information and illustrations do not cover every possible

contingency or circumstance regarding nonstandard options or siteconditions.

If there is a problem, call PFlow Industries, Inc. at (414) 352-9000, during normal

business hours, 8:30 a.m. to 5:00 p.m. central standard time, Monday through

Friday. Outside of those hours, see the PFlow Industries, Inc. Contact Information

page for additional information. Use the model number and serial number or the

PFlow Industries, Inc. General Arrangement (GA) drawing number for the li in

allcorrespondence.

Equipment damage resulting from modication in any manner from the original

model, including the substitution of parts other than factory authorized parts, will

void thewarranty. Furthermore, PFlow Industries, Inc. will not be liable for any loss,

injury, or damage to persons or property, nor for direct, indirect, or consequential

damage of any kind resulting from modied or substitution of parts other than

factory authorized parts of said material or equipment.

PFlow Industries, Inc. maintains a complete stock of, or has access to, all replacement

components. Detailed records of all equipment sold are kept. If a component is

damaged in shipment, is defective or missing, contact PFlow Industries immediately.

The PFlow Industries, Inc. Product Support Department will assist maintenance

and service personnel with any questions or problems regarding the equipment

orinstallation.

Your feedback is important. Please help PFlow Industries, Inc. understand if the

equipment has met your expectations. Please complete the questionnaire in this

manual. The questionnaire will help us address any comments and/or concerns.

Introduction

General

Overview

Code

Requirements

Parts

Service

Feedback

NOTE