MFC International Powermat User manual

1

© MFC International 2017

Product Manual

12 bar

Powermat

2

© MFC International 2017

Warnings

Components

Technical Data

Materials List

Operational Instructions

Maintenance & Test Procedures

Storage

3

3

4

5

6

7

9

WARNING: Carefully read this manual before operating

NOTICE: The manufacturer takes no responsibility for the

consequences of actions not complying with the instructions

given in this manual.

Index

3

© MFC International 2017

• Ensure that this equipment is used only by trained personnel.

• PowermatsshouldonlybeinflatedusingMFCInternationalcontrolequipment.

• Neverexceedtheworkingpressureof12bar.

• EnsurethatPowermatsareprotectedfromhotexhausts.

• Keepclearofloadswhichareunsupportedbychocksduringliftoperations.

• Operatorshouldbepositionedawayfromthedirectionofanticipatedthrust

particularlywhenmakingspacewithpartially-insertedPowermats.

• Neverworkunderaloadwithoutsafetysupports.

• DonotusedeliveryhoseforretrievingorrepositioningPowermats.

• Do not stack Powermats.

• Ensureallgaugesarereadingzerobeforedisconnectinghose.

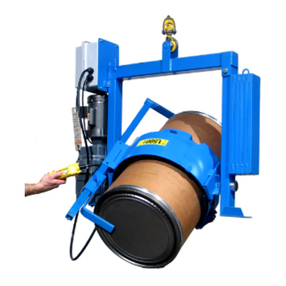

Standard components

2xPowermats(A).

2x10mDeliveryHosec/wsafetylockcouplings(B).1xDualController/Regulatortype

530/855(C).

1xHighPressureConnectingHosec/wbleedvalve(D).

Optional accessories

CarryingValisefor2xPowermats(notshown).CarryingValiseforDeliveryHose(notshown

C

A

B

D

Warnings

Components

12.0 bar

4

© MFC International 2017

Note: alldimensionsareaccurateto±3%andallweightsareaccurateto±5%.

Delivery Hose (controller to powermat)

10mmI/D,ReinforcedPVCHose.

Max.Workingpressure:16bar@23degrees.11Bar@60degrees

Standardlengthsupplied:10metres

Quickreleasesafetylockcouplingseachend.

High Pressure Hose (cylinder to controller)

6mmI/D,doublewirereinforcedsyntheticrubberhose.

Max.Workingpressure:400Bar

Standardlengthsupplied:450mm

Colour:Black

Technical Data

KS2 KS5 KS8 KS16 KS18 KS23 KS30 KS43 KS49 KS68 KS81 KS97

Product Code

KS02/12 KS05/12 KS08/12 KS16/12 KS18/12 KS23/12 KS30/12 KS43/12 KS49/12 KS68/12 KS81/12 KS97/12

Length (cm) 15 22.5 27 38 40.8 46 52 62 65.8 77.5 84 92

Width (cm) 15 22.5 27 38 40.8 46 52 62 65.8 77.5 84 92

Inated height

(cm)

8 13 16 23 25 28 32 38 41 48 52 57

Deated height

(cm)

2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5

Maximum lift

(tonne)

257.5 15.6 18.1 23.2 30 43.2 48.8 68.4 80.7 97.2

Air capacity at

12 bar (litres)

4 18 34 100 128 180 268 449 565 906 1151 1518

Weight (kg) 0.5 1.3 1.8 3.6 4.1 5.1 8 12 13.5 14.5 20 23

Max Pressure

(bar)

12 12 12 12 12 12 12 12 12 12 12 12

5

© MFC International 2017

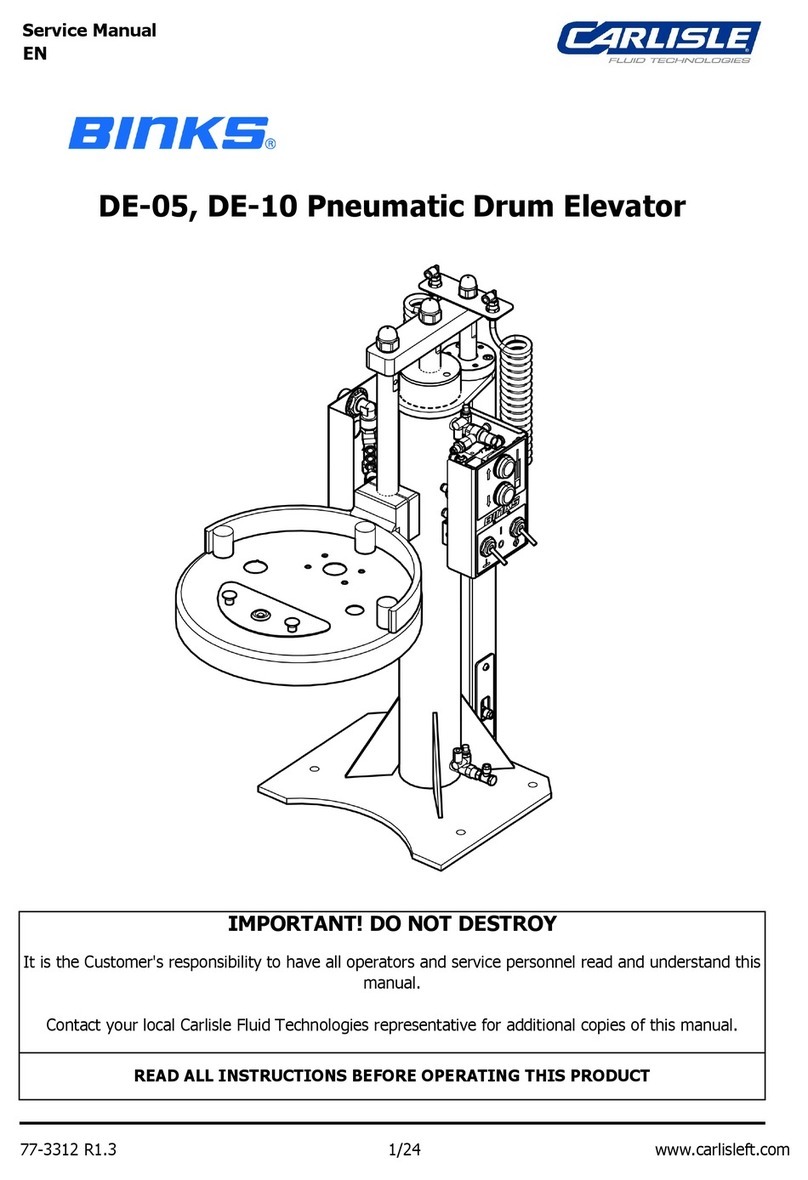

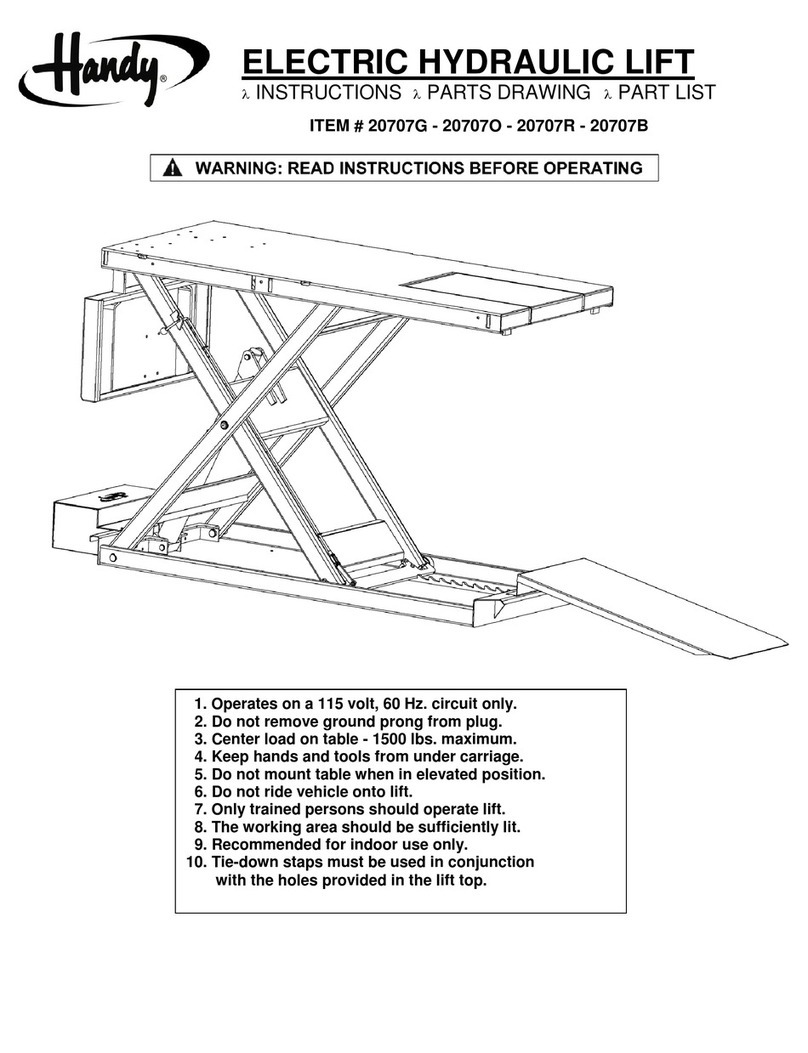

MFC COMBINED CONTROLLER/ REGULATOR TYPE 530/855

TheType530/855CombinedControllerregulatespressureoutputandgivesindependent

control to each cushion.

Theleveractuatedcontrolvalvesarethreepositionalprovidingforinflationordeflation.

Theyaresuppliedwithspringloaded“deadman”automaticreturntoocontrol.TheRelief

Valveisspringloadedwithnitrilerubberseals,re-seatingwithin-10%ofpre-setpressure.

1

5

2

1

4

3

3

1. 12.0BarpanelMountGuage.Lum.Ctd.Dial(airbagpressure).

2. 0-400BarpanelMountedGuage(cylinderpressure).

3. Leveractuatedspoolvalve.

4. Nylonwebadjustablecarrying/handlingshoulderstrap.

5. MFCprod/serialNo.label.

Materials List

W22.3XD20XH15.5cm

Weight:5.54Kgs

12.0

6

© MFC International 2017

• Assesstheweightloadtobelifted,selectsizeofPowermattobeused–Two

Powermatsusedintandemdoublestheliftpotential.Stabilityoftheliftingoperation

shouldbemonitoredthroughout.

• Do not stack powermats.

• InsertthePowermatwellundertheloadtoachievestabilityandmaximum

surfacecontact.

CAUTIONS:

• Avoidcontactwithsharporjaggedsurfacesastheymay

puncturethesurfacecausingthePowermattofail.

• Hotexhaustsshouldbecoveredwithafoldedfireand

heatresistantblanket.Failuretodosomaydamagethesurfaceofthe

Powermat.

• Takeallthenormalprecautionsagainstthedangerof

outbreakoffire,suchaslayingoutchargedlineofhoseorfoambranch

as appropriate.

WARNING: Withanyliftingoperation,safetysupportstructuresareessential.Carrying

outworkunderaloadsupportedonlybyaninflatedairbagisextremely

dangerousandiscontrarytoallsafetyguidelinesandinstructions.

1. ConnectthedeliveryhosesbetweenthePowermatsandcontroller.

Ensuredeliveryhosesarewelllaidoutandnot‘kinked’,maintaininga

clear line to respective Powermats.

2. Connecthigh-pressurehosefromcylindertocentreportonrearof

controller(Max.controllerinletpressureis300bar).

CAUTION:Ensurecontrollerleversarein‘o’positionbeforeopeningairsupply.

3. Commenceinflationbymovingcontrollever(s)toinflateposition.When

therequiredheightormaximumoperatingpressureof12barisreached,

releasetheinflationlever.WhenusingtwoormorePowermats,

balanceairinputbyattentiontocontrollergauges.

4. Onceinflated,donotattempttodisconnectthehosecouplingsfromthe

Powermats.DoingthiswillcausethePowermatstodeflateuncontrollably.

5. Packandblockasliftproceeds,takingcaretoseeblocksareplacedso

that,ifnecessary,theycansupporttheload.

Operational Instructions

7

© MFC International 2017

6. Shouldachangeofcylinderberequired,closethecylindervalve.

Disconnectbymeansofcylinderadaptorhandwheelandreconnectto

chargedcylinder.

7. Afteruse,deflatebyselectingrelevantpositionofcontrollever.Deflationis

thereverseoftheinflateprocedure.

ThefollowingMaintenanceandTestProceduresshouldbeobserved,andcarriedoutby

properlyqualifiedpersonnel.

Periodic Testing / After Operational Use

1. WashdownPowermatsurfacethoroughlywithwarmsoapywater.

2. ExaminesurfaceareathoroughlybeforeInitiallyinflatingthePowermatto

0.5bar.Carryoutafurtherthoroughexaminationandmarkoanycuts

orabrasionswithchalk.Increasethepressureto2.4bar(35psi)andrepeat

thevisualcheck.Allowtostandfor3minutes.

3. Examinemarkedareasandlookforanyfurthercuts,abrasions,andany

obviousdeformityoftheinflatedcushion.Ifthereisevidenceofany

damageordeformity,thepowermatshouldbewithdrawnfromservice.

Itcanthenbereturnedtothesupplierforexpertexaminationifrequired.

4. Shallowsurfacecutsorabrasionsshouldnotaecttheefficiencyofthe

Powermat.Inthecaseofholesorcuts,throughwhichtheinnerfabric

isvisible,theairbagsshouldbewithdrawnfromoperation.IfaPowermat

leaks,itisNOTrepairable.Iftheuserisuncertainabouttheconditionofa

damagedPowermat,itshouldbereturnedtothesupplierforexpert

examination.

5. InflatethePowermatto4bar(58psi)maximumandchecktheinlet

couplingwithsoapywater.Thoroughlywipedrybeforereturningto

storage.

Delivery Hoses

Periodicallyorafteroperationaluse,checkforabrasionmarks.Chargehosetoworking

pressurewithhosedisconnectedfromPowermat,usesoapywatertocheckairholding

integrityofconnections.Tightenloosefittingswherenecessary.

Maintenance & Test Procedures

8

© MFC International 2017

Annually

Annualtesttobecarriedoutbythemanufacturer,orafullyqualifiedcompetentbody.

UK:MFCInternationalLtdhasafacilityfortesting,whichcustomersandbrigade

personnelmayobserve.Alsoavailableisanon-siteservicevehicle,pleasecontactour

servicingdivisionforfurtherinformation.

Overseas:Contactagentforadviceoffacilitiesavailable.

Dual Controller Type 530/855 - Quarterly and after Operational Use

1. Visuallyinspectcontrollerforsignsofdamage.

2. Checkmechanicaloperationofflowcontrollevers.

3. Connectcontrolunittoairsourcebymeansofreduced-pressurehose

fromcylinderordirectlyfromcompressor(maximuminletpressure300

bar).

4. Withcontrolleversinthe“OFF”positionturnonairsupply.Check

integrityofinletsupplyconnections.Connectdeliveryhosesto

controllerbutnottothePowermats.Movecontrolleverstoinflate

position.Checkfunctioningofreliefvalvesbyreferencetodischarge

pressurelineonfaceofgauge.Thereliefvalvesshouldventat12.0bar

+/-10%.

5. Withcontrollerpressurisedcheckforleaks.Aleakisindicatedbya

pressuredecreaseontheAirbagPressureGauge(NOTE:allowthe

pressurereliefvalvestore-seatbeforecheckingforleaks).Ifaleakis

detected,pleasecontacttheservicingauthorityimmediately.

6. Thoroughlywipedownanddrycontrollerbeforestoring.

9

© MFC International 2017

Storage

Powermatsshouldbestoredinaclean,dustfreeenvironmentandinaccordancewithBS

3574whichstates:

• StorageTemperaturebetween10ºCand25ºC.Humiditybelow75%.

• Protectionagainstlight,particularlydirectsunlightorintenseartificiallight

withhighultra-violetcontent.

• Avoidequipmentcapableofgeneratingozonee.g.highvoltageelectrical

equipment.

Storage

10

© MFC International 2017

11

© MFC International 2017

MFCInternational

Naval Yard

Tonypandy

RhonddaCynonTa

CF401JS

T.+44(0)1443433075

F.+44(0)1443420448

www.mfc-international.com

ARespirexInternationalLimitedGroupCompany SA-MA72-01

This manual suits for next models

12

Table of contents

Popular Lifting System manuals by other brands

Pentair

Pentair AQUATRAM 90 Installation and user guide

ATD Tools

ATD Tools ATD-7321A owner's manual

Bishamon

Bishamon FP3500 Operation manual

morse

morse 195 Series Operator's manual

Ravaglioli

Ravaglioli RAV 635.1 ISI Translation of the original instructions

The Handy

The Handy 20707G INSTRUCTIONS, PARTS DRAWING, PART LIST

Grainger

Grainger 12R538 instruction manual

Upright

Upright AB-46 Bi-Energy Operator's manual

probst

probst TAS-UNI Translation of original operating instructions

Tuxedo

Tuxedo TP9KF-TUX Installation & operation manual

Extreme Max

Extreme Max Boat Lift Buddy Installation & use instructions

Suspa

Suspa Movotec SMS installation instructions