ZP 3 M delivery pump / Part 2 Overview, operation and service

Table of contents

Table of contents

1 General information................................... 6

1.1 Information regarding the operating

manual.............................................. 6

1.2 Division............................................. 6

1.3 Display of safety and warning

notices.............................................. 6

1.4 Keep the manual for future refer-

ence.................................................. 7

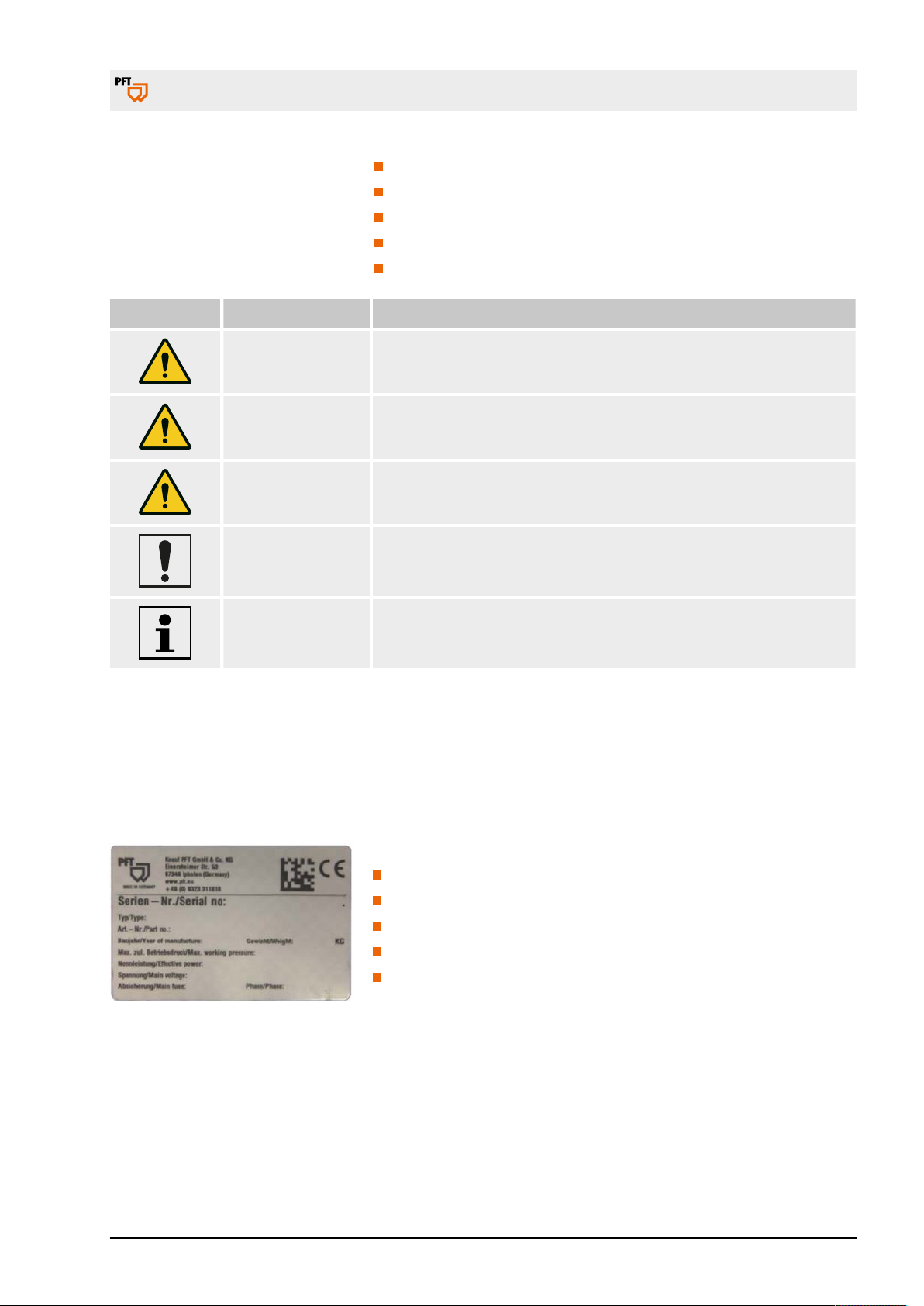

1.5 Name plate....................................... 7

1.6 EC Declaration of Conformity........... 8

1.7 Quality Control sticker...................... 9

1.8 Intended use.................................... 9

1.8.1 Purpose of air compressor............... 9

1.8.2 Safety devices of air compressor..... 10

1.8.3 General setup of the air compressor 10

1.8.4 Hot surfaces on the air compressor.. 10

2 Technical data............................................. 11

2.1 General information.......................... 11

2.2 Operating conditions........................ 11

2.2.1 Operating conditions FC-230V 50Hz 12

2.2.2 Operating conditions 230V 60Hz...... 12

2.2.3 Operating conditions FC-400V......... 13

2.2.4 Operating conditions 400V pole-

changing........................................... 13

2.3 Performance values pump unit 2L6

RENDER STAR................................ 13

2.4 EMC test.......................................... 14

2.5 Sound power level............................ 14

2.6 Vibrations.......................................... 14

3 Transport, packing and storage................ 15

3.1 Safety instructions for transport........ 15

3.2 Transport inspection......................... 16

3.3 Packaging......................................... 16

3.4 Transport.......................................... 17

3.5 Crane transport................................ 17

3.6 Transport by car or truck.................. 17

3.7 Transporting a running machine....... 18

4 Description.................................................. 19

4.1 Overview - ZP 3 M........................... 19

4.2 Functional description ZP 3 M.......... 19

4.3 Fields of application......................... 20

4.4 Description of assemblies................ 20

4.4.1 Material hopper................................ 21

4.4.2 Control cabinet item no. 00531100... 21

4.4.3 Control cabinet item no. 00531101... 22

4.4.4 Control cabinet item no. 00531102... 22

4.4.5 Control cabinet item no. 00617410.. 23

4.4.6 Pump unit......................................... 23

4.4.7 Vibrating screen............................... 23

4.4.8 Air compressor................................. 24

4.4.9 Mortar pressure gauge..................... 24

4.5 Operating modes.............................. 25

4.6 Accessories...................................... 26

5 Operation..................................................... 30

5.1 Safety............................................... 30

5.1.1 Safety rules...................................... 30

5.1.2 Monitoring the machine.................... 31

5.1.3 Hazardous dusts.............................. 31

5.1.4 Safety system................................... 31

5.1.5 Mortar pressure gauge..................... 32

5.2 Inspection by machine operator....... 32

5.3 Preparing the machine..................... 32

5.3.1 Risk of injury due to rotating pump

shaft.................................................. 32

5.3.2 Setting up the machine.................... 33

5.3.3 Connecting the power supply........... 33

5.3.4 Checking the direction of rotation..... 35

5.3.5 Mortar hoses.................................... 37

5.3.6 Drain residual water......................... 39

5.3.7 Compressed air supply.................... 39

5.3.8 Feeding material to the machine...... 41

5.4 Shutdown in case of emergency...... 41

5.5 Putting the machine into operation... 42

5.5.1 Checking the mortar consistency..... 42

5.5.2 Feeding material to the machine...... 43

5.6 Remote control................................. 44

5.7 Applying mortar................................ 44

5.7.1 Opening the air tap on the spray

gun.................................................... 44

5.8 Pump screed or masonry mortar...... 45

5.9 Interruption of work.......................... 45

5.9.1 In case of longer interruption of

work / break...................................... 46

5.10 Switching off the air compressor...... 47

5.11 Switching off the air compressor...... 47

5.12 Switching off the machine................ 47

5.13 Action in case of power failure......... 48

5.13.1 Discharging mortar pressure............ 49

5.13.2 Switching on the machine again

after a power failure......................... 49

5.14 Measures in case of risk of frost....... 50

5.15 Ending work / cleaning the machine. 51

5.15.1 Cleaning........................................... 51

page 4 / 72